Coaxial double-bar ejection-type cylindrical gear-elliptical bevel gear planetary system wide-narrow row seedling slinging mechanism

A technology of cylindrical gear and elliptical cone, which is applied in the field of coaxial double-rod ejection cylindrical gear-elliptical bevel gear planetary system wide and narrow row rice seedling throwing mechanism, can solve the problems of high processing precision, low work efficiency, complex structure, etc., and achieve Increase the ejection link, save labor costs, and improve the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the utility model will be further described.

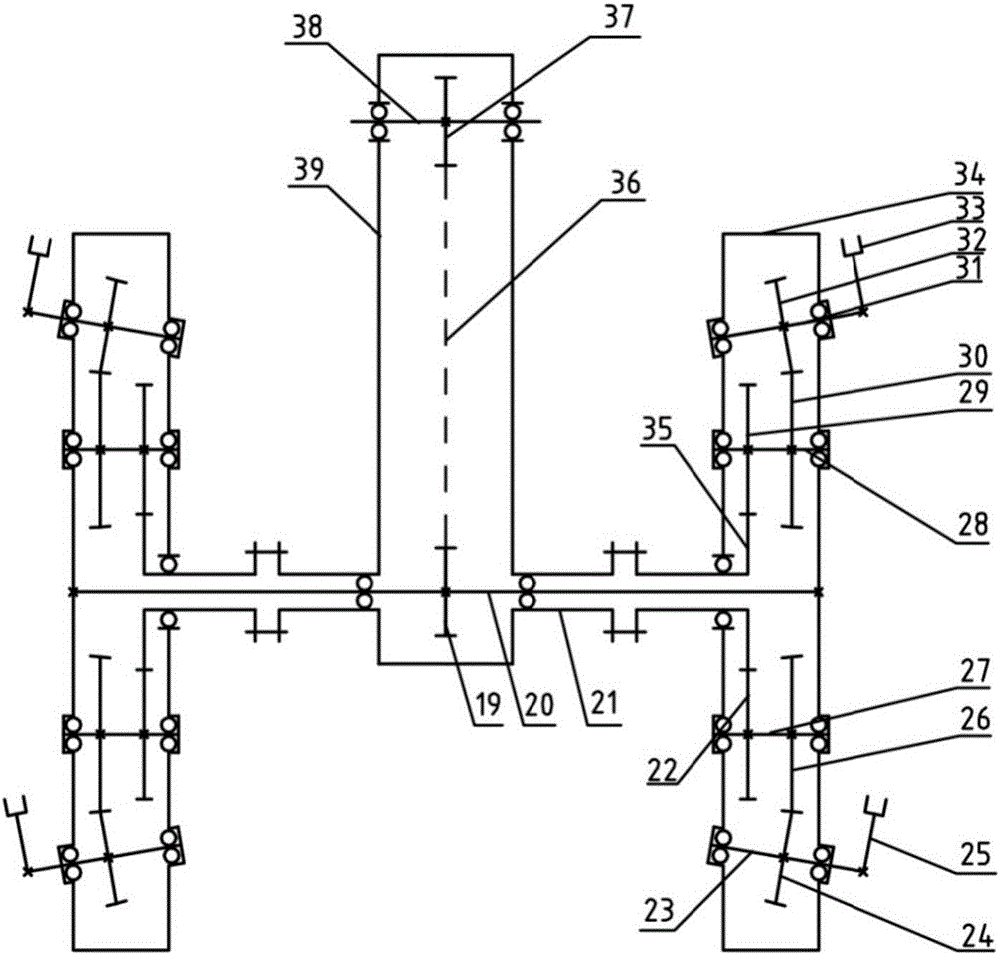

[0035] Such as figure 1 As shown, the present invention is installed on the transmission parts of the seedling throwing machine, and the transmission parts include a sprocket box 39, and the power in the sprocket box 39 is passed through the chain 36 by the driving sprocket 37 installed on the driving sprocket shaft 38 Transfer to the central sprocket 19, the central sprocket 19 is fixed on the central shaft 20, and the two shaft ends of the central shaft 20 are respectively fixed with the present invention with the same internal transmission structure;

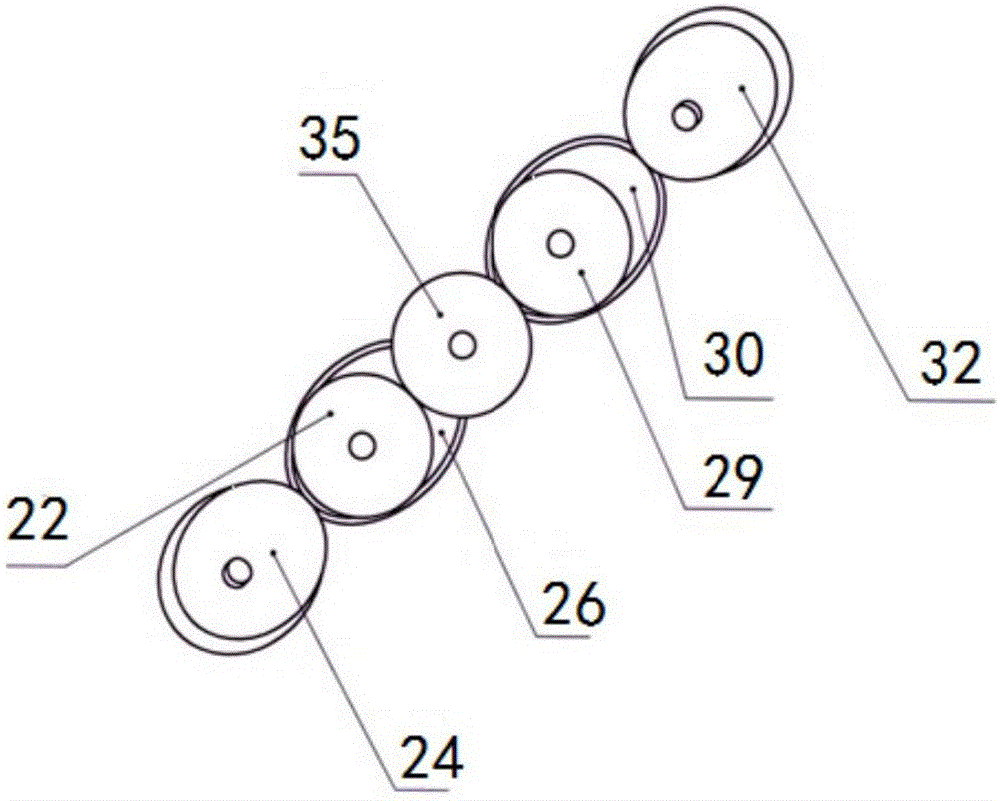

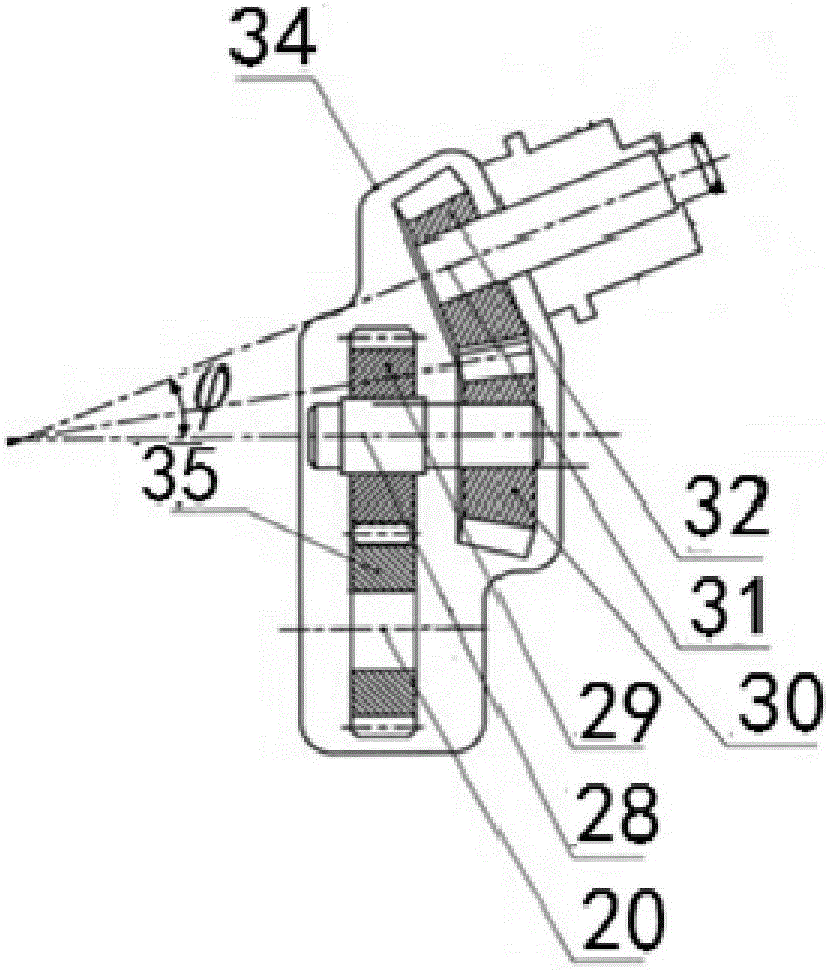

[0036] Such as Figure 1-2As shown, the present invention includes a gear box 34, and a central cylindrical gear 35 in the gear box 34 is vacantly sleeved on one end of the central shaft 20, and is fixedly connected with one end of the sprocket box 39 through the tooth-embedded flange 21, and the central cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com