Check valve capable of controlling fast and slow closing by means of variable throttle

A check valve, a variable technology, applied to the valve's device for absorbing fluid energy, control valve, valve device, etc., can solve vibration and water hammer, cannot fully provide the inherent function of the check valve, and cannot realize the check valve. Valve inherent function and other issues to achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

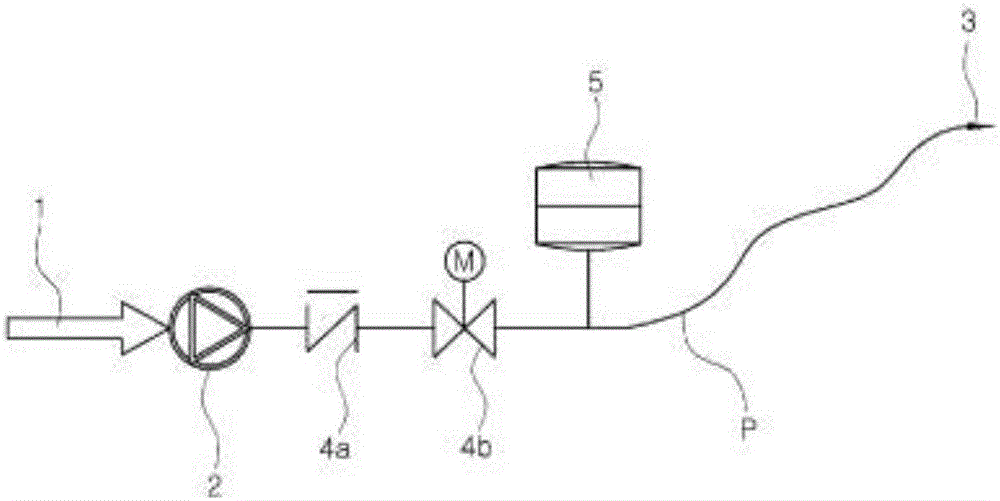

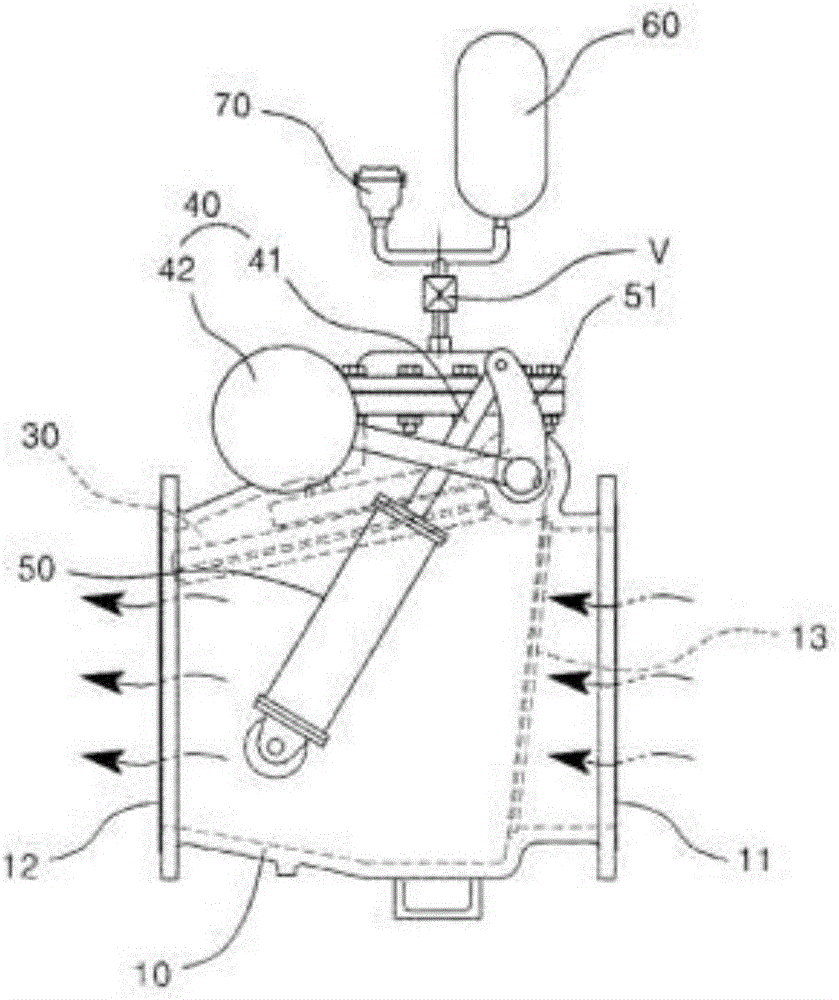

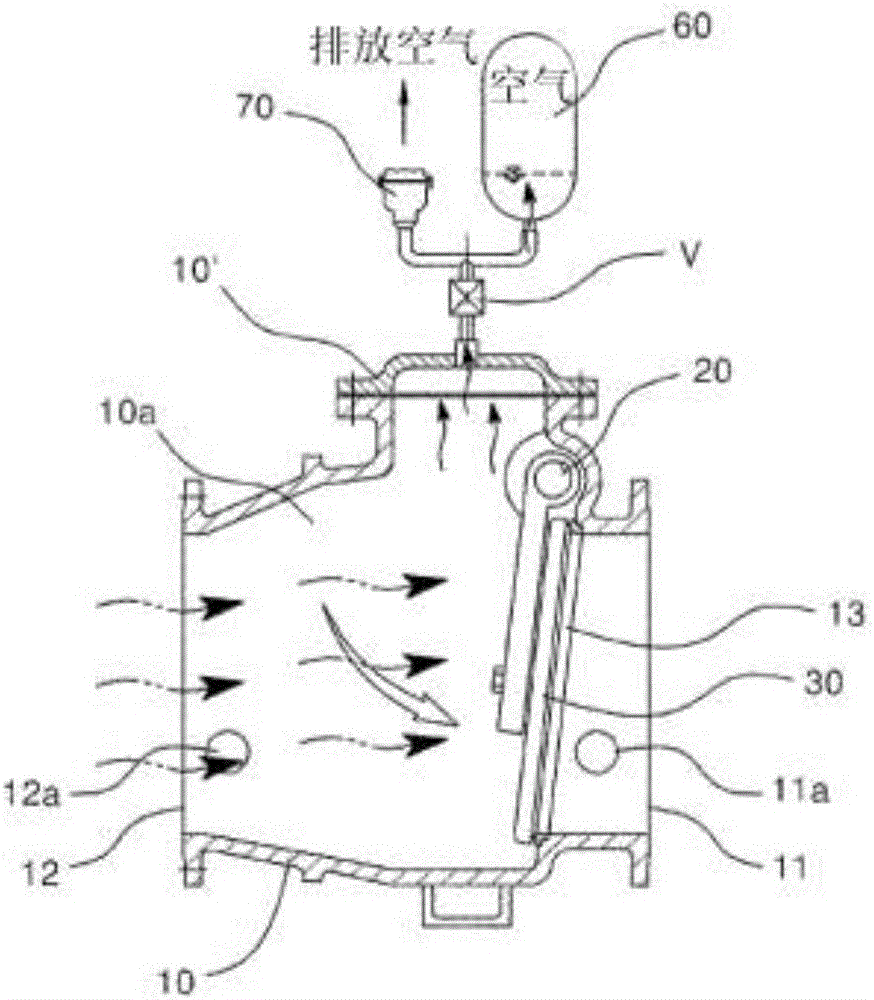

[0054] A check valve that can adjust fast closing and slow closing by means of variable throttling according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0055] First, if Figure 4 and Figure 5 As shown, the check valve of the present invention that can adjust fast closing and slow closing by means of variable throttling includes: valve body 110, cover plate shaft 120, cover plate 130, balance counterweight 140, buffer damper 150, equipped with adjustment Button (CB) buffer force adjustment device 160, and variable throttle type buffer operator 170.

[0056] Accordingly, in the present invention, when the pump of the water piping system is stopped and the cover plate 130 is covered or the cover plate 130 is opened after the pump returns, the variable throttle type buffer operator 170 is operated in conjunction with the action of the cover plate 130 .

[0057] Therefore, the adjustment but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com