Liquid supply system

A liquid supply and liquid technology, which is applied in the direction of liquid variable capacity machinery, pump components, pulse balance, etc., can solve the problems of ultra-low temperature slurry without wear resistance and loss of elasticity, so as to inhibit bending, inhibit damage, and stabilize the pump The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

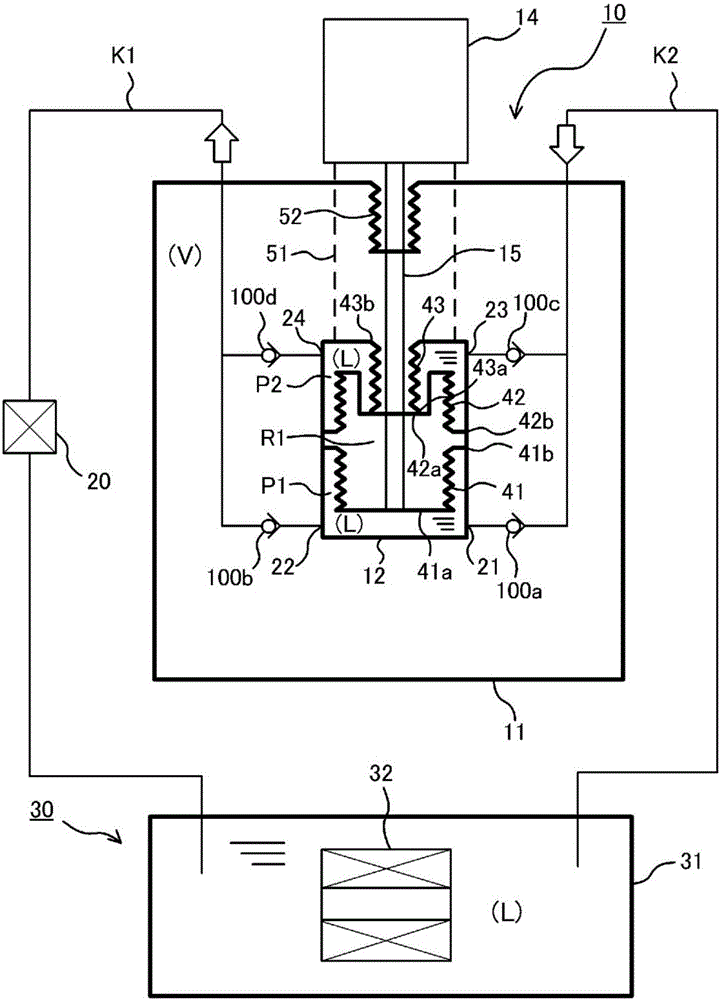

[0066] refer to figure 1 A liquid supply system according to an embodiment of the present invention will be described. figure 1 It is a schematic structural diagram of the liquid supply system related to the embodiment of the present invention.

[0067] The liquid supply system 10 is a pump device for cryogenic fluid, and the liquid supply system 10 always supplies liquid into the container 31 in order to maintain the superconducting cable 32 in a superconducting state in the cooled device 30 having the superconducting cable 32 inside the resin container 31. Ultra-low temperature liquid L. Specific examples of the cryogenic liquid L include not only liquid nitrogen or liquid helium but also liquids having a temperature below the liquid temperature of liquid nitrogen or liquid helium.

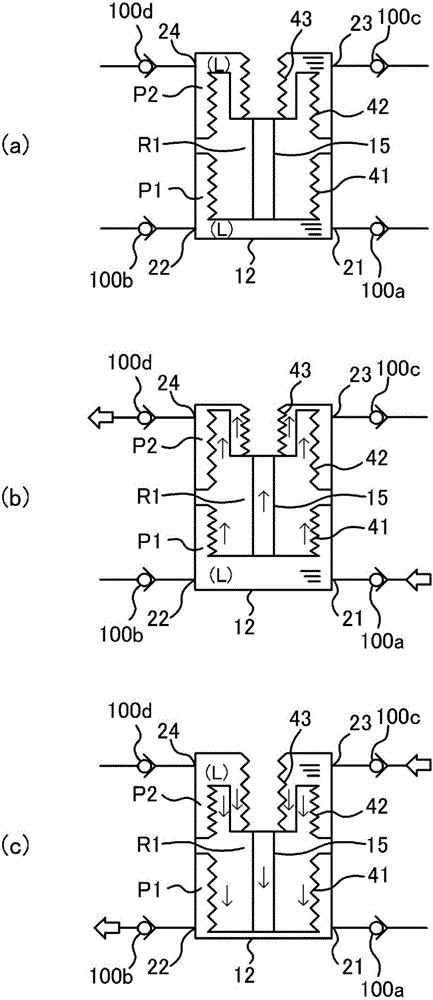

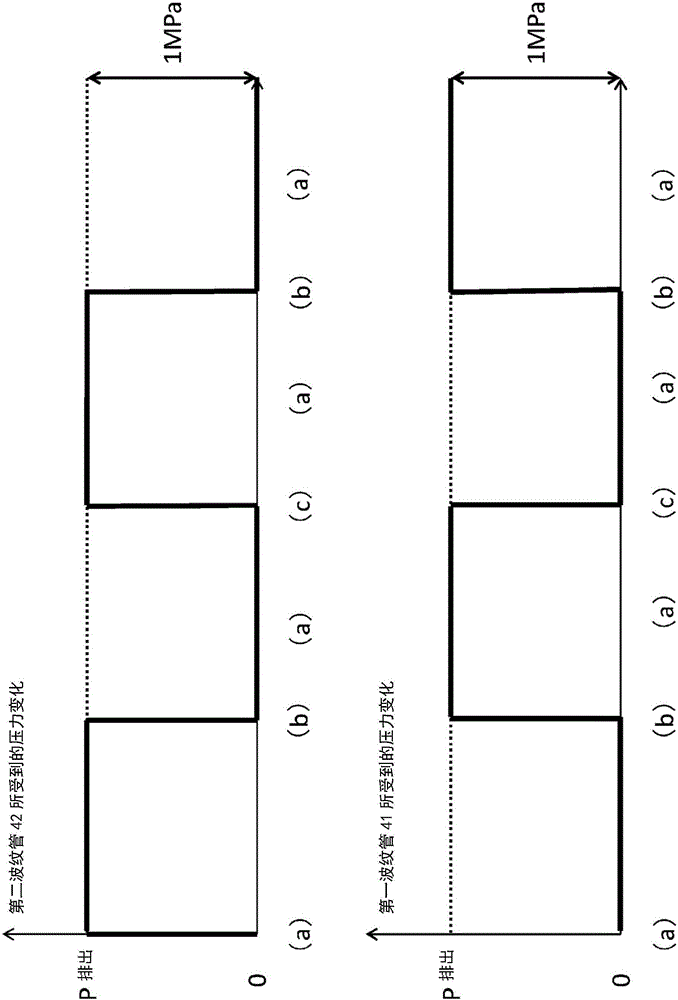

[0068] The liquid supply system 10 roughly includes: a first container (outer container) 11 , the inside of which is vacuum; and a second container 12 arranged to be surrounded by a vacuum spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com