Production method for noodles, and noodle separation improver

A manufacturing method, noodle technology, applied in the direction of dough handling, application, dough preparation, etc., which can solve the problems of lack of simplicity and insufficient effect, and achieve the effect of maintaining elasticity and improving looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

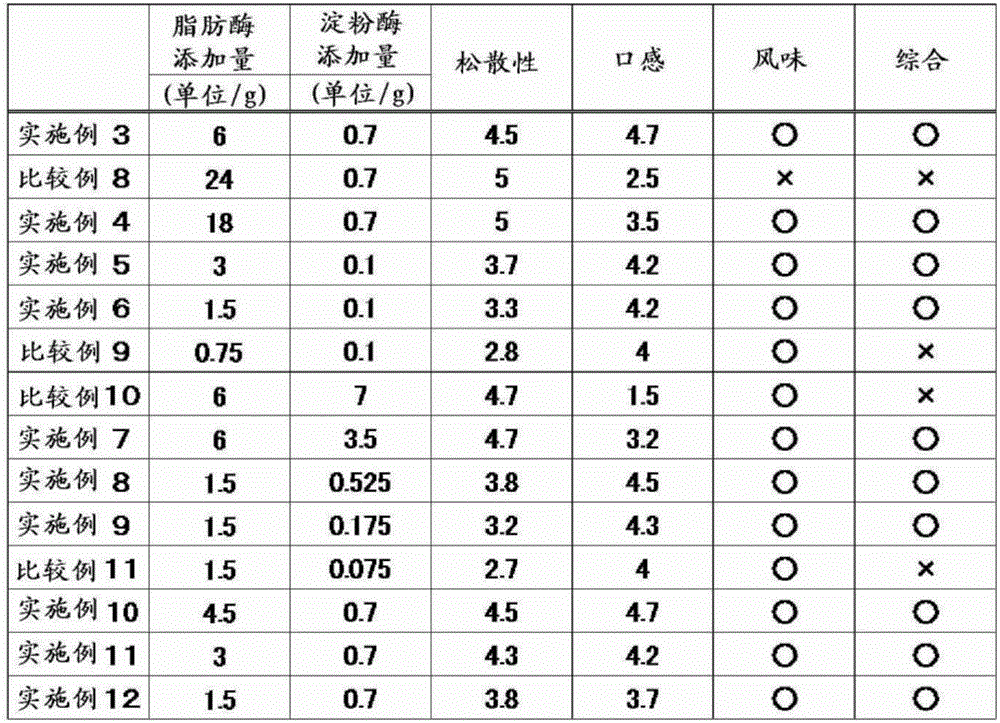

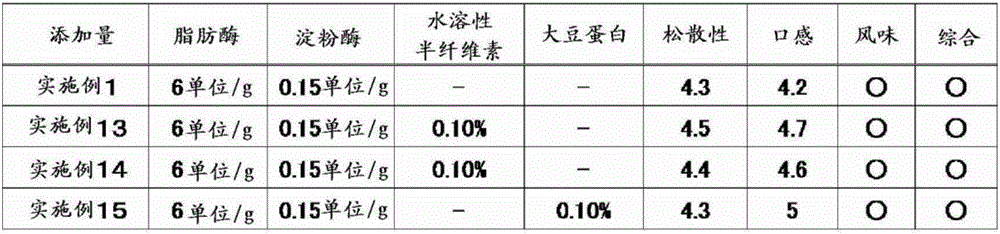

Embodiment 1

[0068] To a mixture of 600 g of wheat flour, 390 g of tapioca starch, and 10 g of wheat gluten, add 20 g of common salt and lipase A “Amano” 6 (Amano enzyme: 60,000 units / g) that is a lipase with 1,3-position specificity 0.1 g of amylase Sumizyme AS (manufactured by Shin Nippon Chemical Industry Co., Ltd.: 1500 units / g) was dissolved in 450 g of water and kneaded to prepare noodle dough. The dough is rolled, and cut out with #20 incisors to obtain Chinese noodles, as Example 1. The Chinese noodles were boiled for 80 seconds, washed with water, divided into hexagonal containers per 100 g, and stored at 4° C. for 2 days. Looseness and noodle quality (elasticity, hardness) of these Chinese noodles were evaluated.

Embodiment 2

[0070] In the method described in Example 1, lipase DF "Amano" 15 (manufactured by Amano Enzyme Co., Ltd.: 150,000 units / g) as a lipase having 1,3-position specificity and Biozyme A as an amylase were used. (Manufactured by Amano Enzyme Co., Ltd.: 7,500 units / g), Chinese noodles were prepared in the same manner as above.

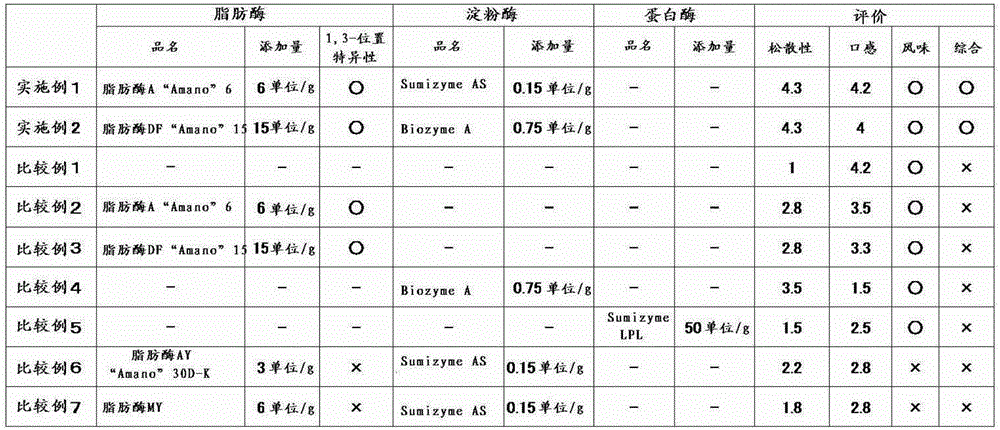

Embodiment 3~12、 comparative example 8~11

[0100] In the method described in Example 1, as shown in Table 2, lipase "Amano" 6, which is a lipase with 1,3-position specificity, and Biozyme A, which is an amylase, were added, and the obtained Chinese noodles were used as an example. Examples 3-12, Comparative Examples 8-11. Table 2 shows the results of the evaluation.

[0101] (Table 2)

[0102]

[0103] The addition amount of lipase having 1,3-position specificity in the range of 1 to 20 units / g and amylase in the range of 0.1 to 5 units / g exhibited good looseness, texture and flavor of noodles. In Comparative Examples 8 to 11 in which the addition of lipase and amylase having 1,3-position specificity was out of these ranges, the looseness deteriorated, or even if the looseness was good, food texture deteriorated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com