Liquid protective structure used for back surface of wafer

A protective structure and wafer technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult removal of chemicals, and achieve the effect of convenient maintenance and replacement, and protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the drawings.

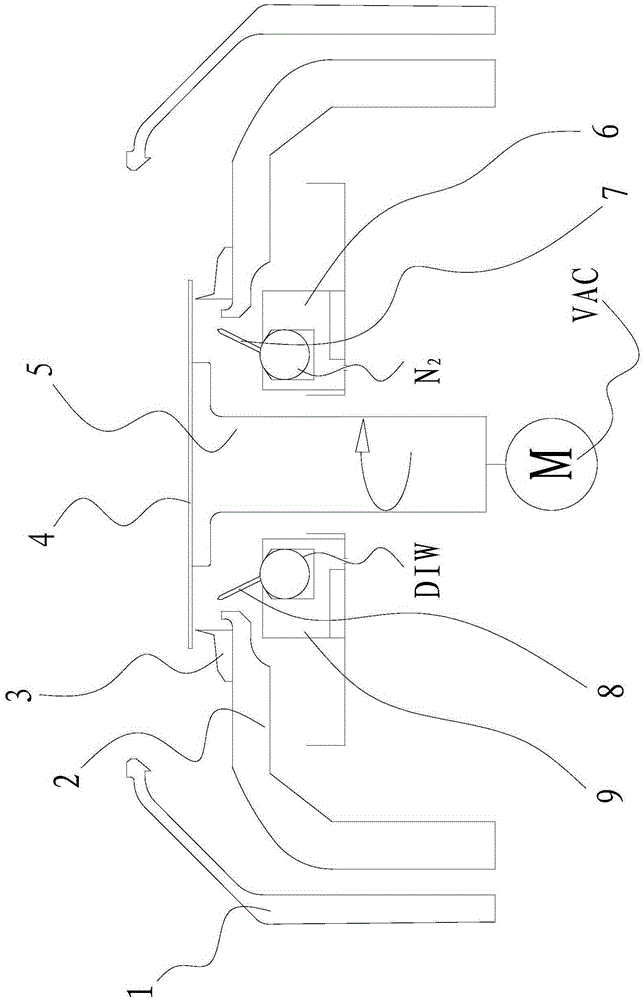

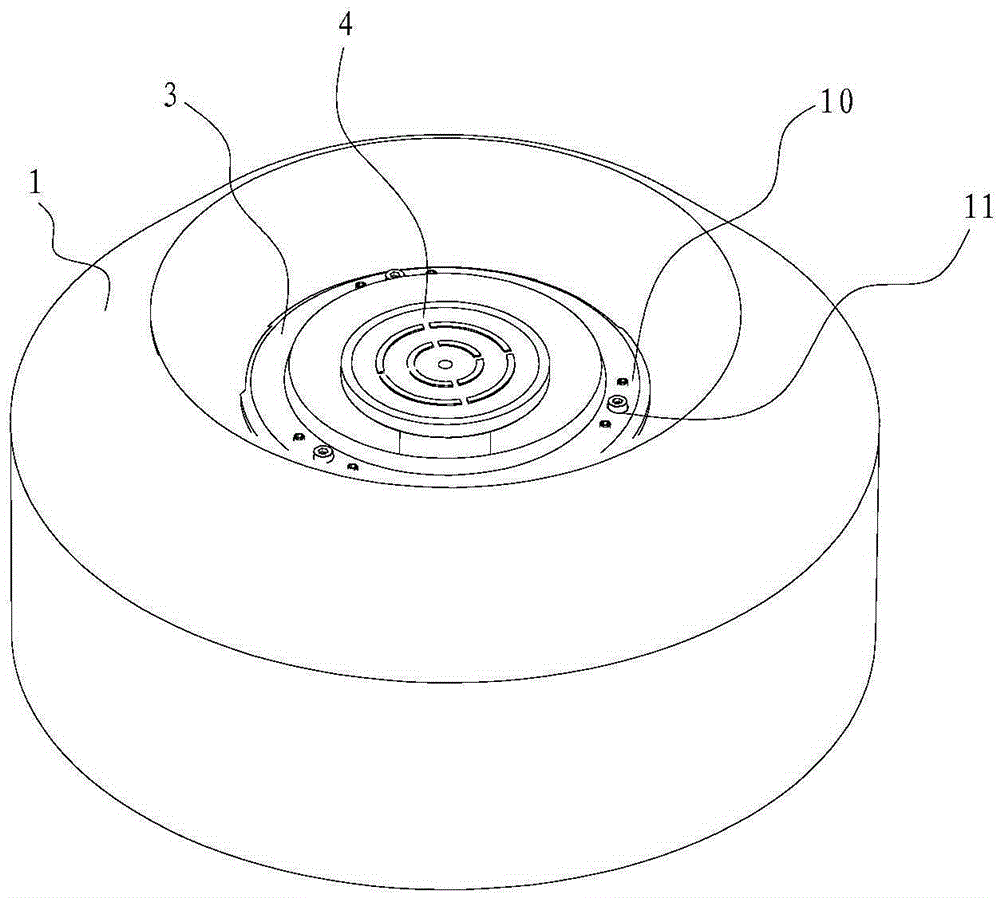

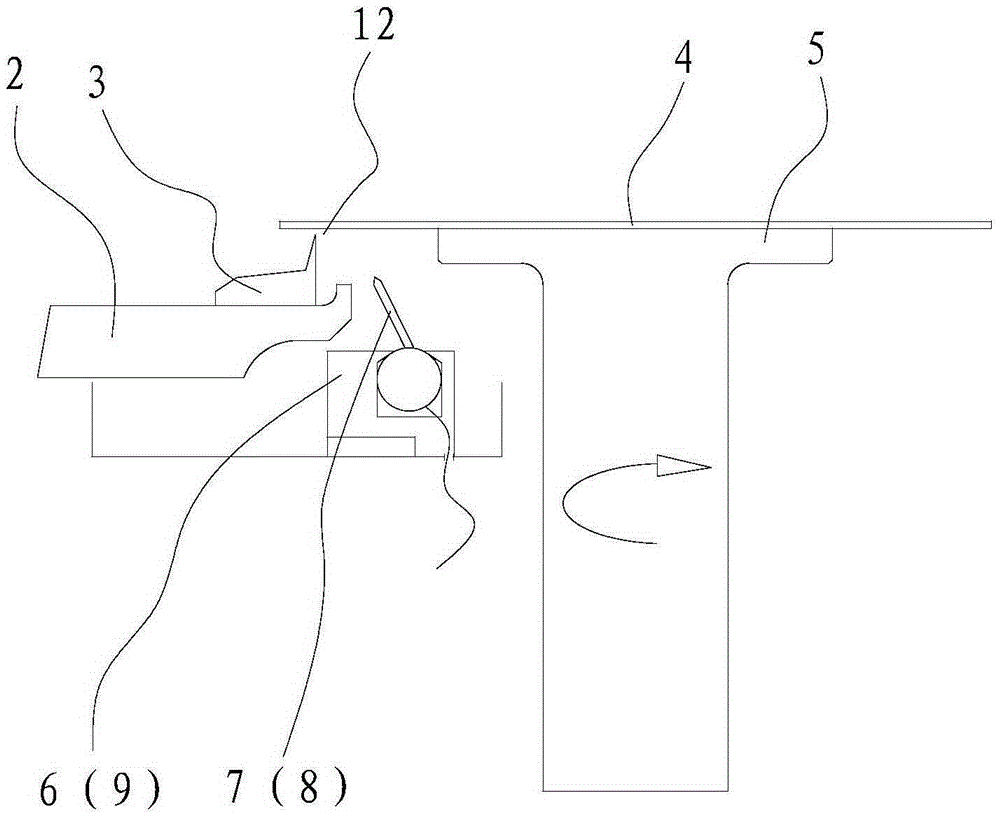

[0025] In a complete development or cleaning process unit, the collection cup is used for chemical protection (to prevent splashing to the outside of the unit) and waste liquid collection, as well as for gas-liquid separation. Such as figure 1 As shown, the liquid protection structure of the present invention includes a collection cup and a vacuum chuck 5 in the collection cup that absorbs the wafer 4 and drives the wafer 4 to rotate. The collection cup and the vacuum chuck 5 are both installed in the process unit. The collection cup is divided into a collection cup outer cover 1 and a collection cup inner cover 2. The collection cup outer cover 1 is the outermost protective layer to completely isolate the process area and the non-process area; the collection cup inner cover 2 is located on the collection cup outer cover 1 The inside is used to separate gas and liquid, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com