A magnetron anode assembly and a magnetron provided with the magnetron anode assembly

An anode assembly and magnetron technology, applied in the field of magnetron, can solve the problems of easy deformation of welding ring, scrapped workpiece, short circuit, etc., and achieve the effects of high welding quality, avoiding welding failure and stable working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

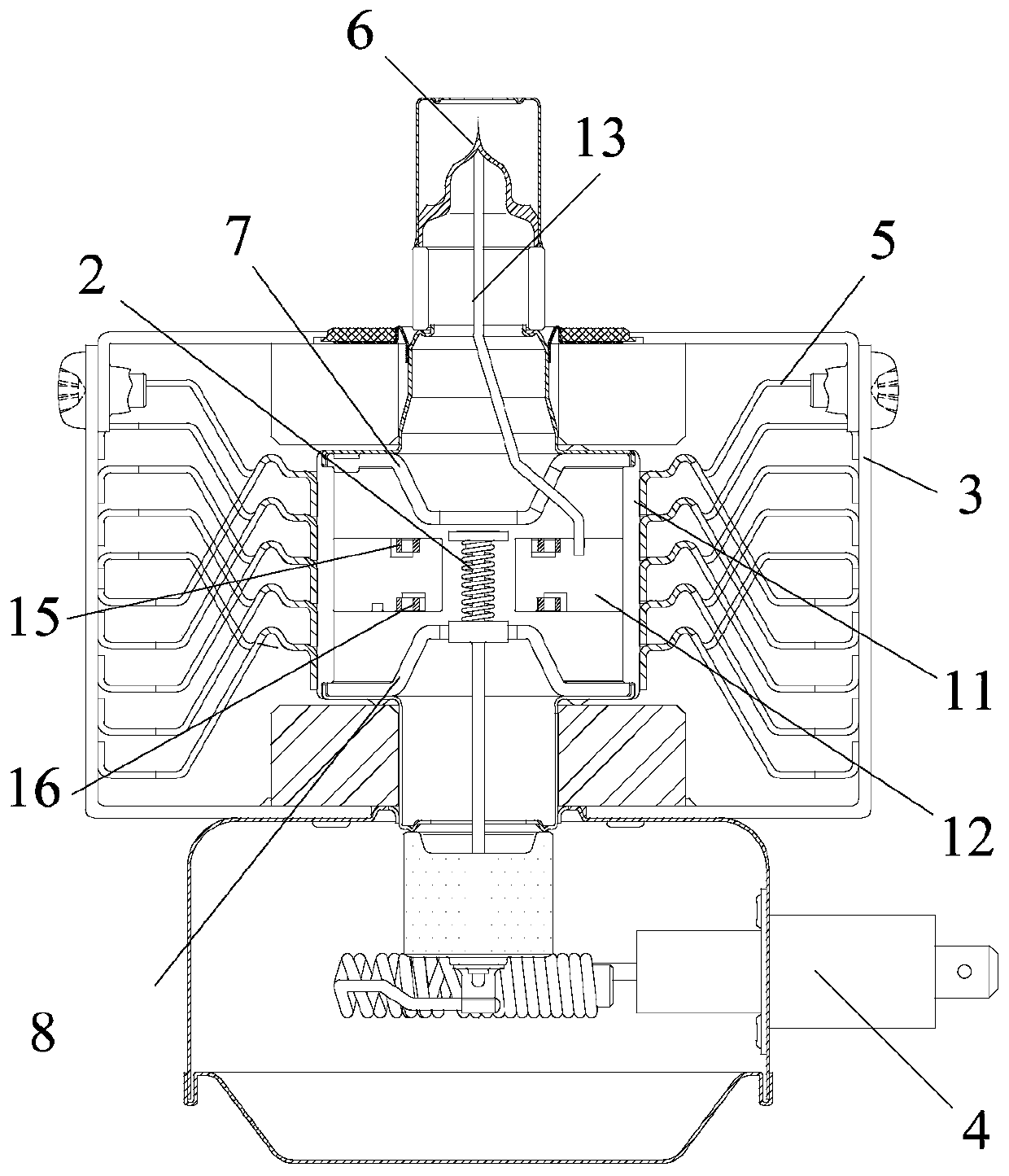

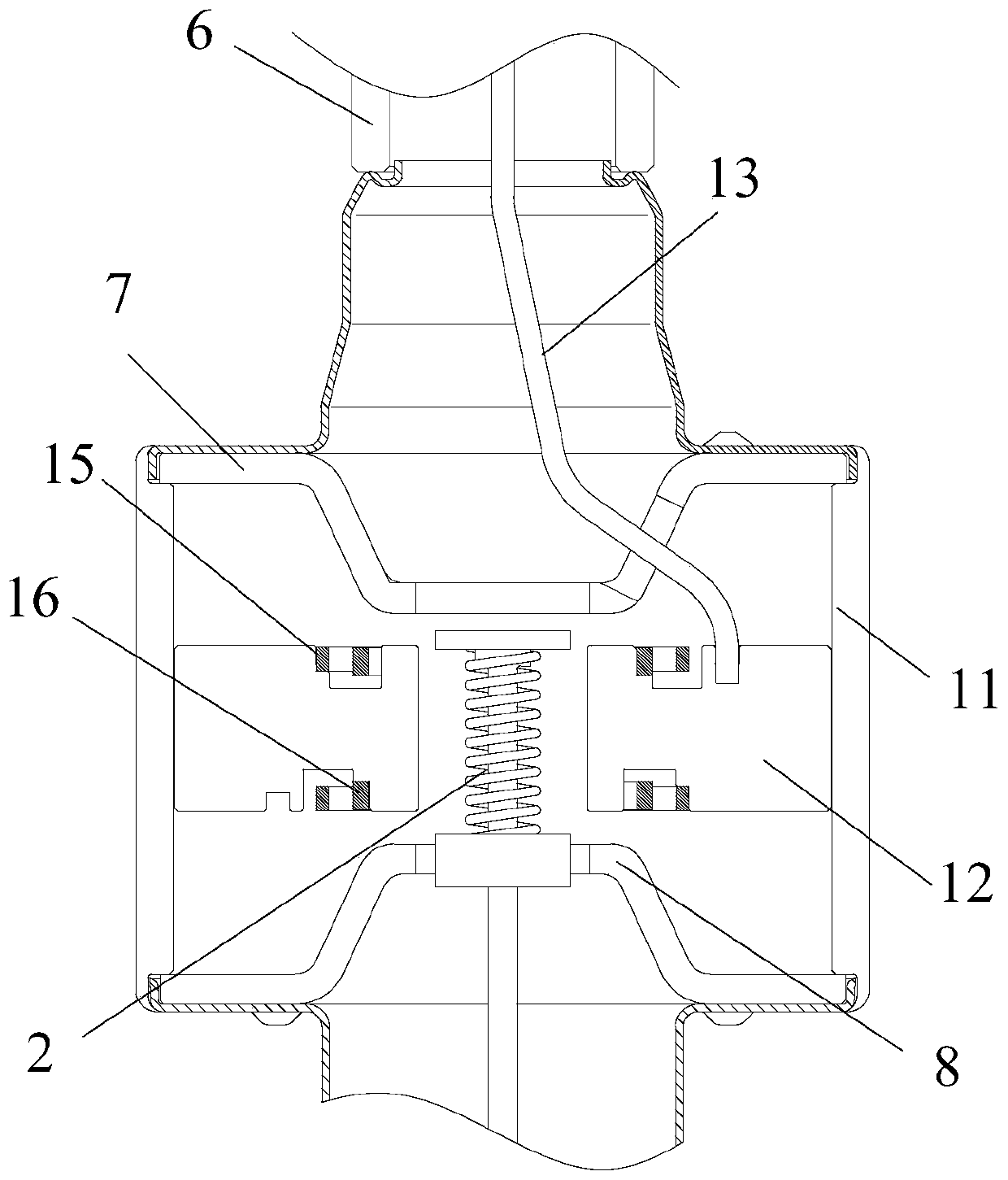

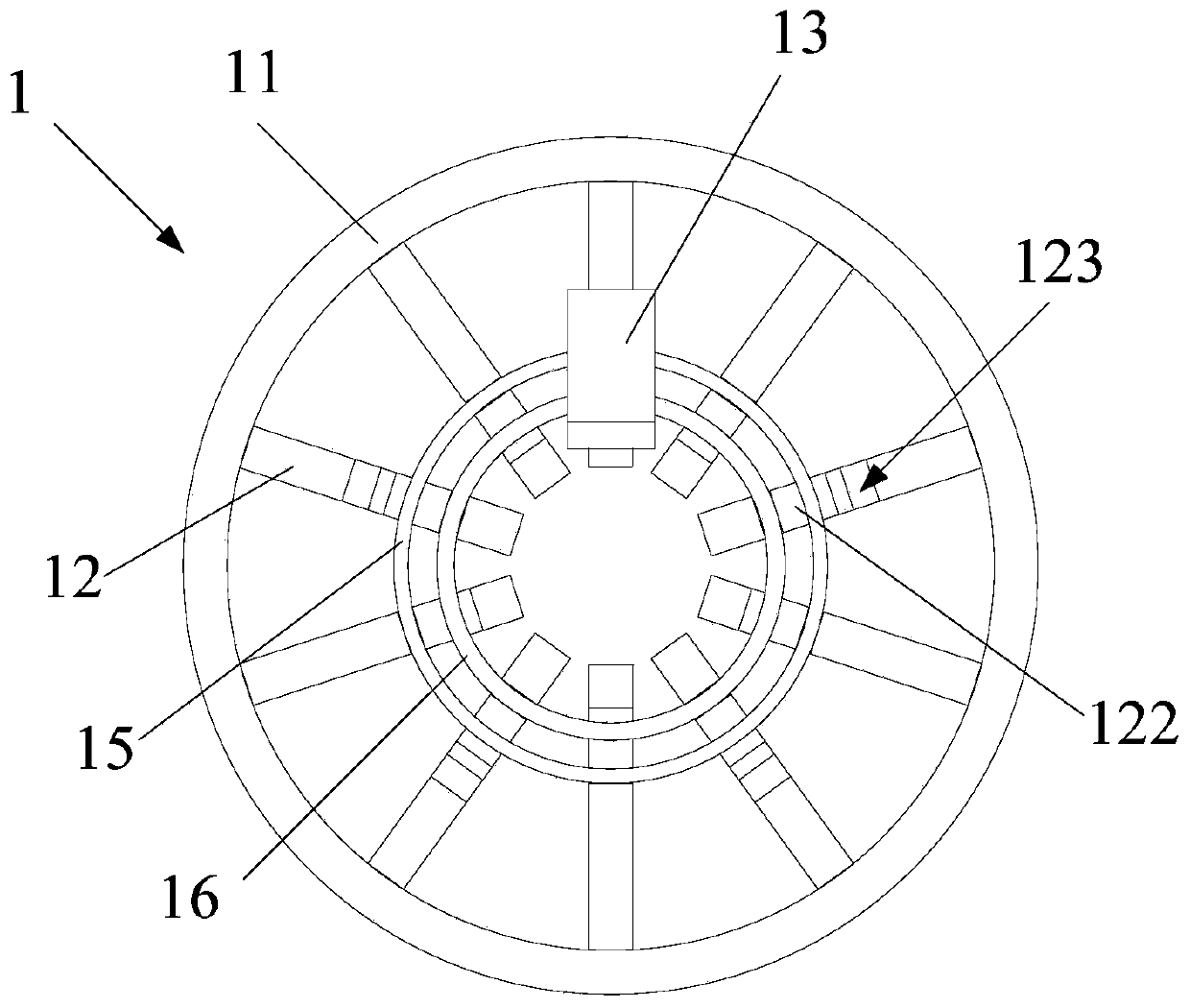

[0043] Such as Figure 10 to Figure 12 As shown, the present invention provides a magnetron anode assembly 1, comprising an anode cylinder 11 and a plurality of radially distributed anode blades 12 arranged in the anode cylinder 11, and a plurality of anode blades 12 One end is respectively connected with the inner wall of the anode cylinder 11, and the other end is a free end, and the joint between each anode vane 12 and the inner wall of the anode cylinder 11 is welded by solder 14; Two diversion grooves 121, two diversion grooves 121 are arranged on the side wall of one side of the diversion groove 121, and the diversion groove 121 includes a first diversion section 1211 arranged horizontally and a second diversion section 1212 arranged obliquely One end of one of the guide grooves 121 extends to the upper surface of the anode blade 12, and the other end extends to the end where the anode blade 12 and the inner wall of the anode cylinder 11 are welded; one end of the other ...

Embodiment 2

[0056] This embodiment is substantially the same as the technical solution in Embodiment 1, the main difference is that two diversion grooves 121 are provided on the side wall of the diversion groove 121 in this embodiment, as Figure 13 and Figure 14 As shown, the guide groove 121 includes a first guide section 1211 arranged horizontally and a second guide section 1212 arranged obliquely, and the length d1 of the second guide section 1212 from the welding end of the anode blade 12 and the anode cylinder 11 is 0- 4mm, and the angle between the second guide section 1212 and the upper surface of the anode vane 12 is 30-90°, because the welding ring used for welding the anode vane 12 is generally placed between the anode vane 12 and the anode cylinder 11 At the gap, if the distance is too large, the solder 14 melted on the upper surface of the anode vane 12 is too far away from the diversion groove 121, and the solder 14 cannot be guided to the welding place between the anode va...

Embodiment 3

[0061] The technical solution of this embodiment is substantially the same as that of Embodiment 1, the main difference is that in this embodiment, only one diversion groove 121 is provided on the same side of the anode vane 12, such as Figure 15 As shown, a diversion groove 121 is provided on the side wall of one side of the diversion groove 121, and one end of the diversion groove 121 extends to the upper surface of the anode vane 12, and the other end extends to the welded joint between the anode vane 12 and the inner wall of the anode cylinder 11. one end. In this way, when the anode vane 12 and the anode cylinder 11 are welded, the solder 14 is melted on the upper surface of the anode vane 12, and then the melted solder 14 flows to the anode vane 12 and the anode vane 12 through the guide groove 121 under the action of capillary action and gravity. At the welding place of the inner wall of the anode cylinder 11 , the anode blades 12 are welded on the inner wall of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com