Polarized light reuse imaging method and micro optical engine system based on optical wand

An optical engine, polarized light technology, applied in optics, instruments, projection devices, etc., can solve the problems of complex manufacturing process, small size of lens unit and polarization conversion device unit, difficult production and processing, etc., to achieve the effect of increasing size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

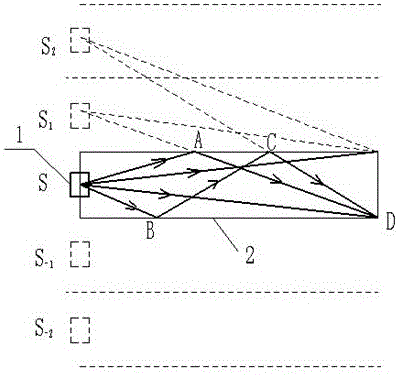

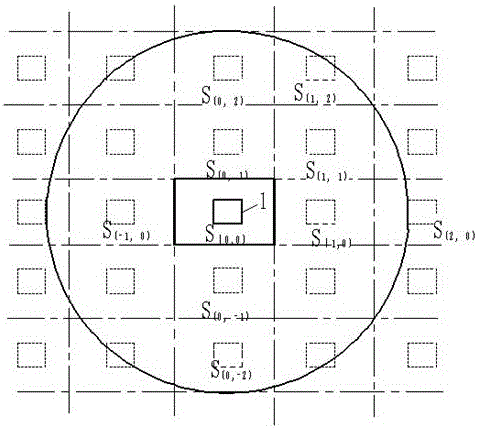

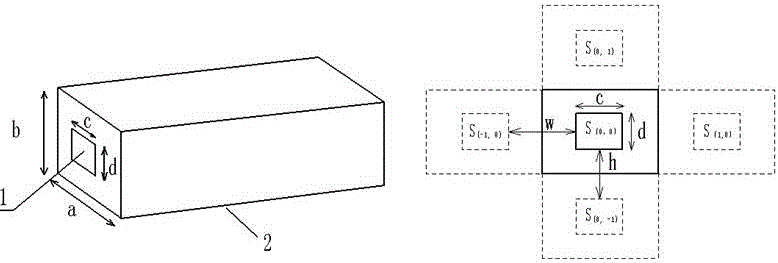

[0034] The traditional compound-eye polarized light multiplexing method uses the basic principle of the compound eye to split the wavefront of the plane wave to realize the beam splitting of the illumination light and complete the polarization conversion; while the polarization multiplexing method based on the cone-rod and 4F optical system does not exist to divide the illumination light The process of segmentation processing in advance will increase the caliber of the original lighting system to a certain extent. The invention mainly provides a polarized light multiplexing imaging method and a micro optical engine system based on an optical rod. The present invention realizes beam splitting and shaping of illumination light by combining non-imaging optics with imaging optics. On the premise that the caliber of the illumination system remains basically unchanged, the secondary imaging of the two-dimensional virtual light source array located at the front surface of the light ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com