A step force generating device for dynamic calibration of force sensor

A force sensor and dynamic calibration technology, applied in the field of sensor testing, can solve problems such as difficulty in application, and achieve the effects of large impact force, high flexibility and high impact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

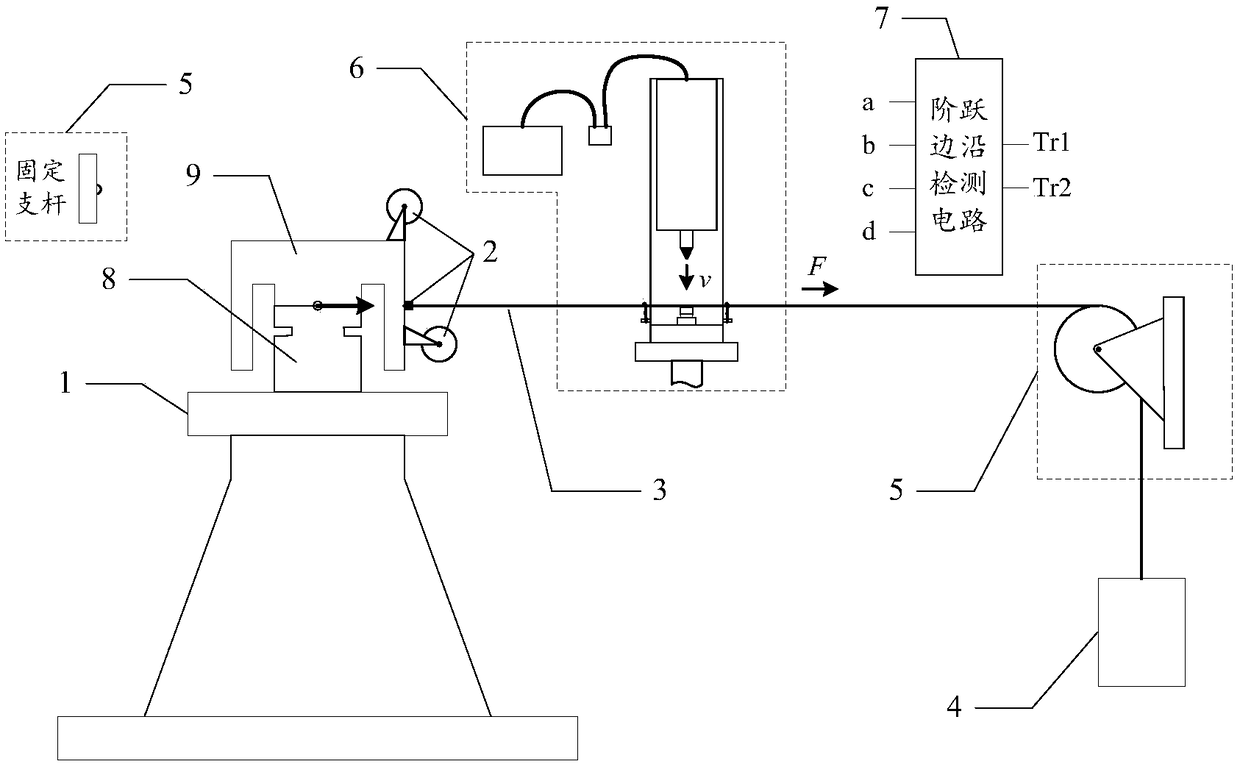

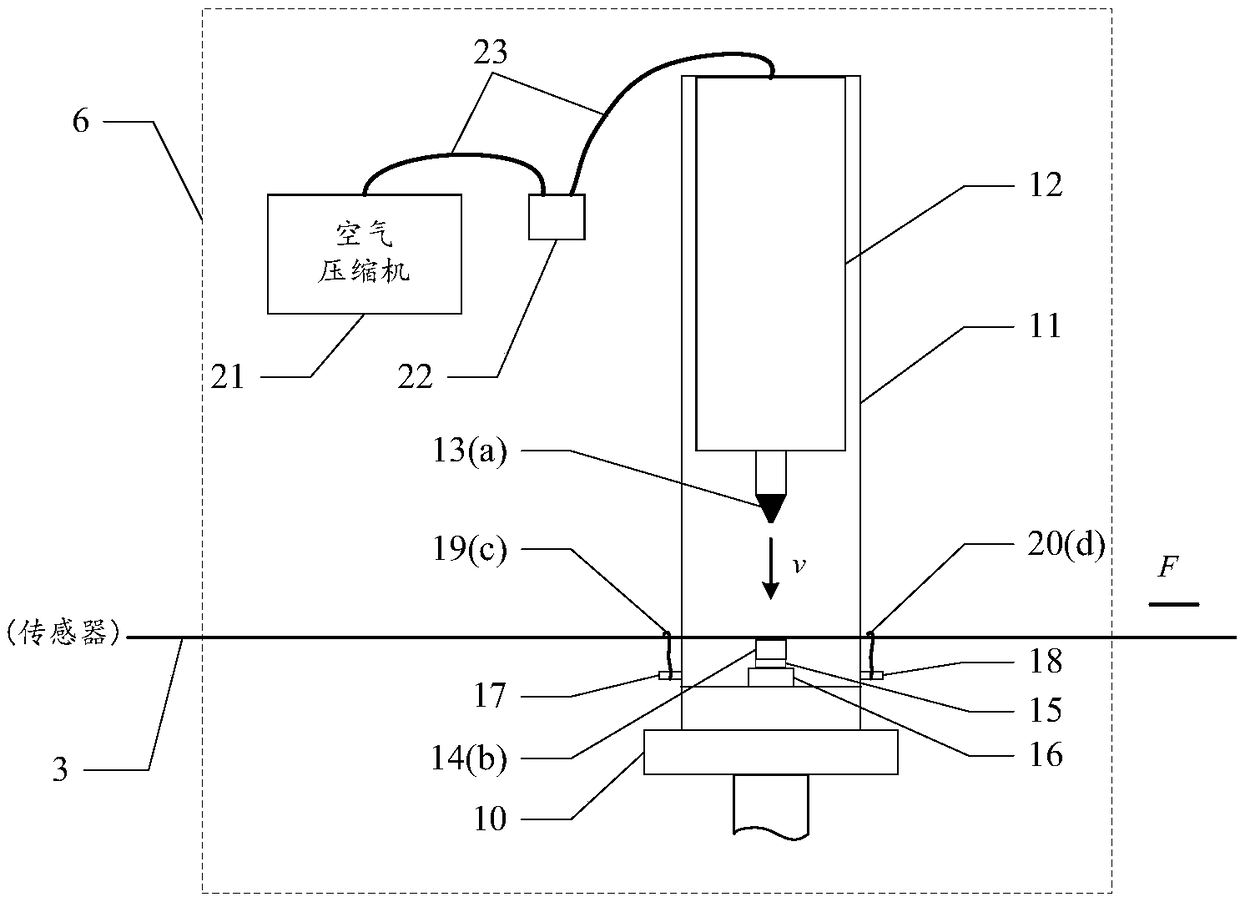

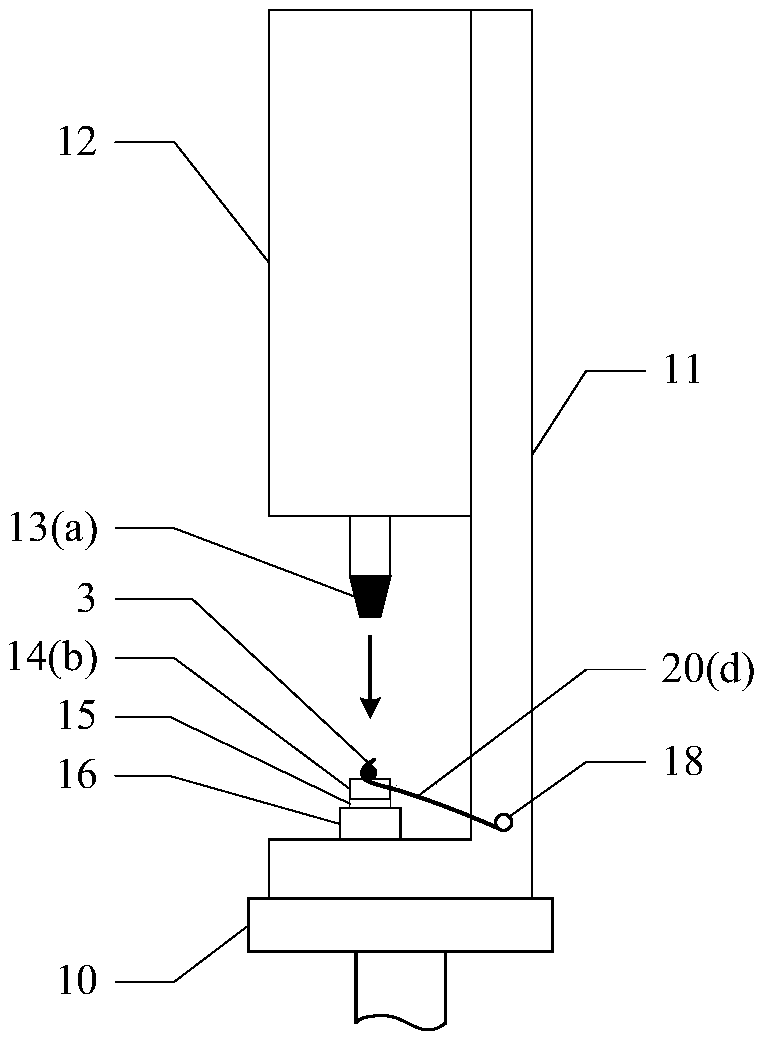

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] The design concept of the present invention is: for the force sensor step response dynamic calibration requirement of the load end tooling with irregular shape or multi-direction force / torque loading, the loading screw and fixed The method of the pulley pair is used to provide a directional loading point in the direction of force and moment, and the steel wire is used as the force transmission part to apply the force generated by the force source to the force direction or moment direction to be calibrated by the force sensor through the loading screw or fixed pulley pair, and then use Instantaneously cut the steel wire method to realize the negative step response dynamic calibration of the force sensor; the high-speed, high-impact impact cylinder is used to drive the impact head to impact and shear the force-transmitting steel wire, which can cut thicker steel wire mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com