Method for measuring gas flow through ultrasonic flowmeter

A gas flow and flow measurement technology, applied in the field of metering instruments, can solve problems such as flow measurement error and gas flow disturbance, and achieve the effects of high measurement accuracy, accurate measurement of gas flow, and real-time monitoring of pipe network status.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

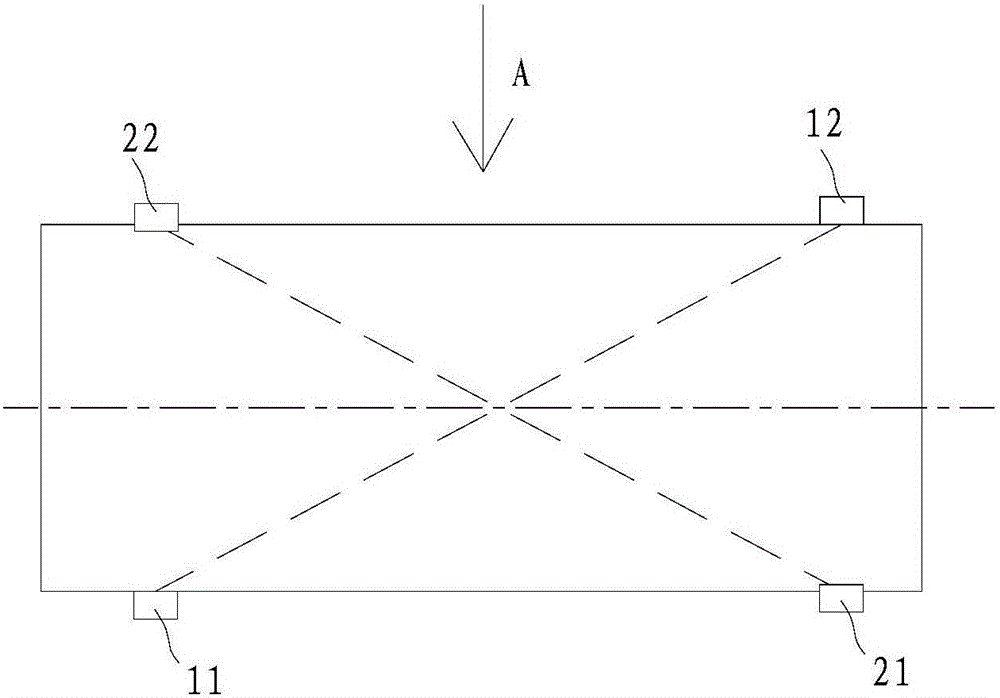

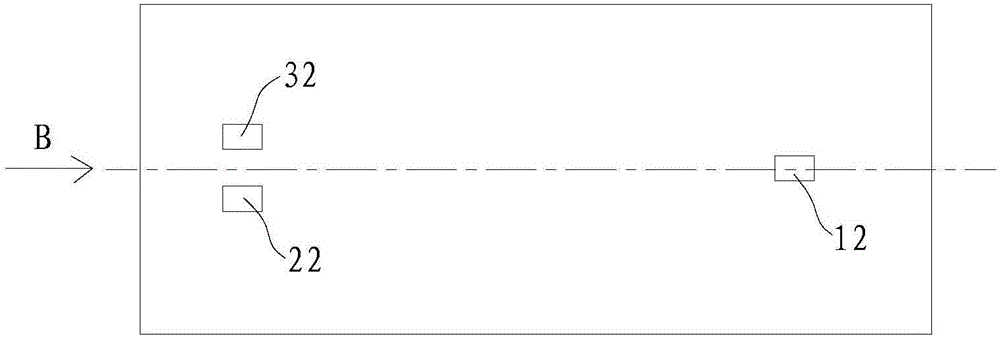

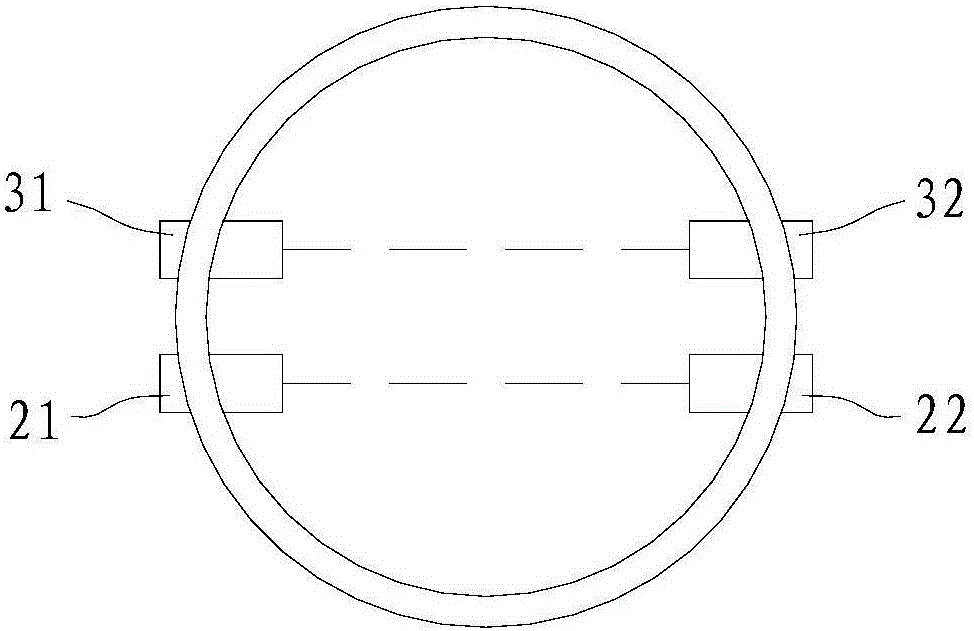

[0040] The method for measuring the gas flow rate by using an ultrasonic flowmeter according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] The present invention utilizes ultrasonic flow meter to measure the principle of gas flow as follows:

[0042] During the process from the ultrasonic signal sent by the ultrasonic probe upstream of the air flow to the ultrasonic probe downstream of the air flow receiving the ultrasonic signal, because the gas flow generates a velocity component in the transmission direction of the ultrasonic signal, the transmission of the ultrasonic signal will be accelerated; During the process of receiving the ultrasonic signal from the ultrasonic signal to the ultrasonic probe upstream of the gas flow, the gas flow generates a velocity component in the transmission direction of the ultrasonic signal, which will slow down the transmission of the ultrasonic signal, and use the ultrasonic si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com