Tape core

A core seat and body technology, applied in the field of tape measure cores, can solve the problems of large coil spring rewinding pre-tightening force, separation of the ruler core cover from the ruler core seat, and easy occurrence of radial deformation, so as to prevent radial distortion and deformation. , prolong the service life, the effect of firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

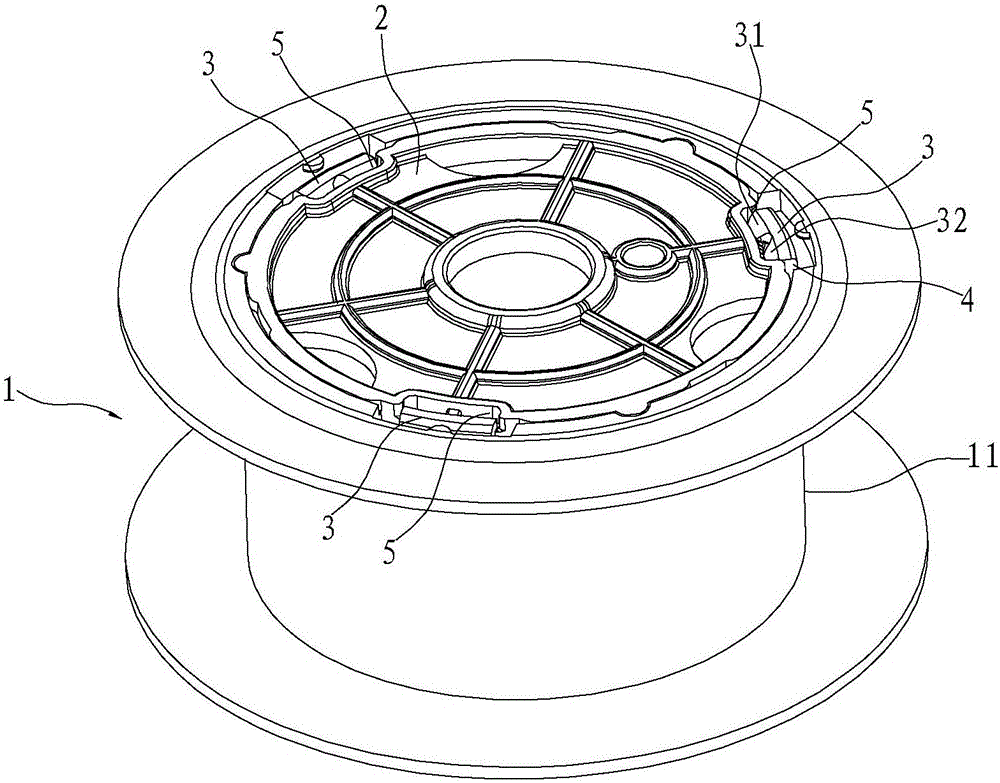

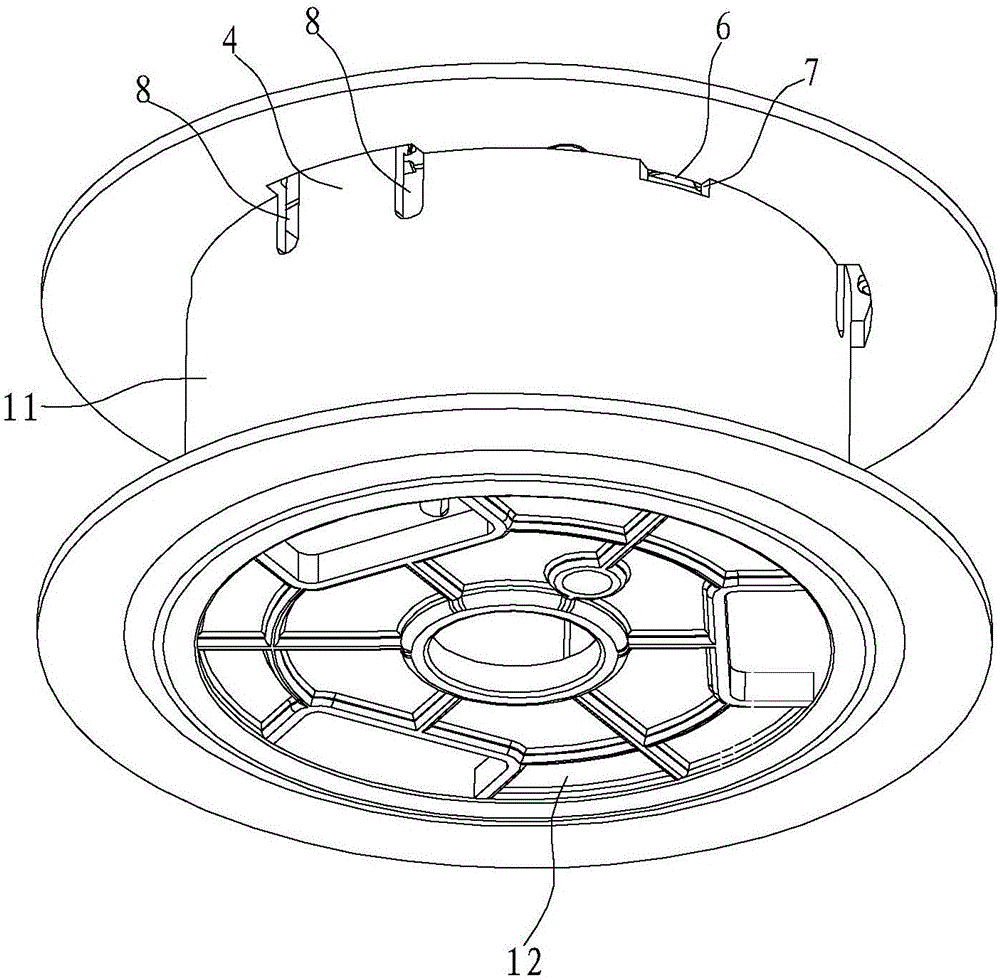

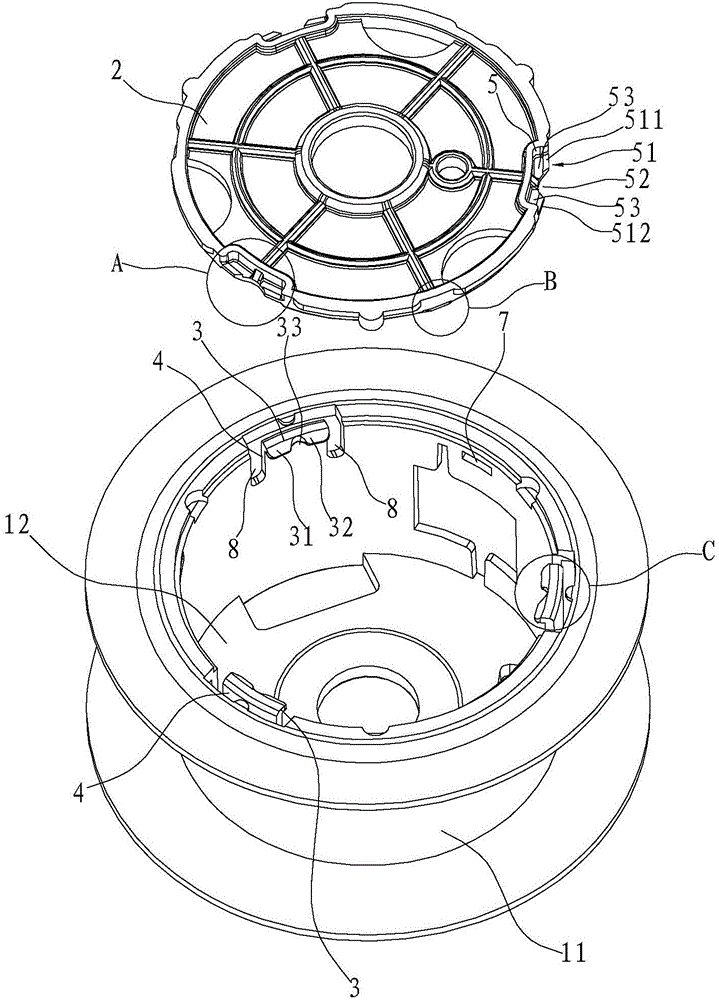

[0020] Such as Figure 1-9 As shown, a tape measure core includes a core base 1 and a disc-shaped core cover 2, wherein the core base 1 includes a cylindrical body 11, and one end of the body 11 is covered by a chassis 12 Hold and open the other end.

[0021] The end of the above-mentioned opening wall is provided with at least three radially inwardly protruding baffles 3 , and the baffles 3 are evenly arranged along the circumference of the opening. In this embodiment, the blocking pieces 3 are three pieces. Specifically, the side walls of the body 11 are provided with first notches 8 at intervals, and the side walls of the body between two adjacent first notches 8 form connecting pieces whose ends are suspended. 4, and the blocking piece 3 is arranged at the end of the connecting piece 4.

[0022] Correspondingly, the above-mentioned rule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com