Ignition electrode cap

An ignition electrode and electrode hole technology, applied in the direction of combustion ignition, ignition using electric spark, combustion method, etc., can solve the problems of high-frequency interference, loosening, high-current impact of control circuit, etc., to weaken high-frequency oscillation, improve Robustness and reliability of contact, effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

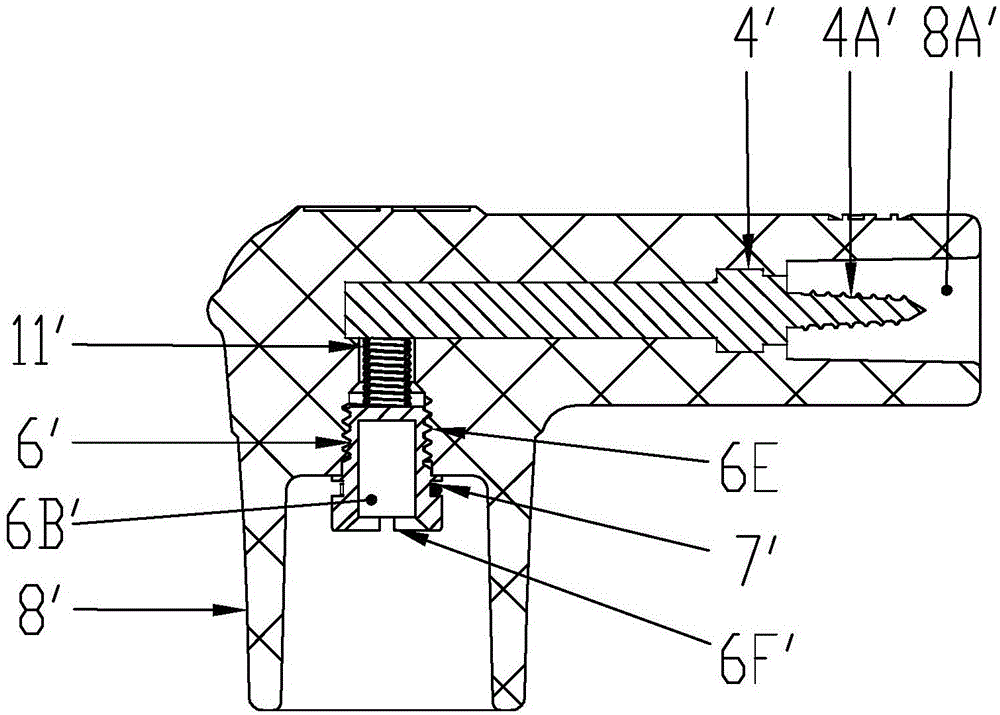

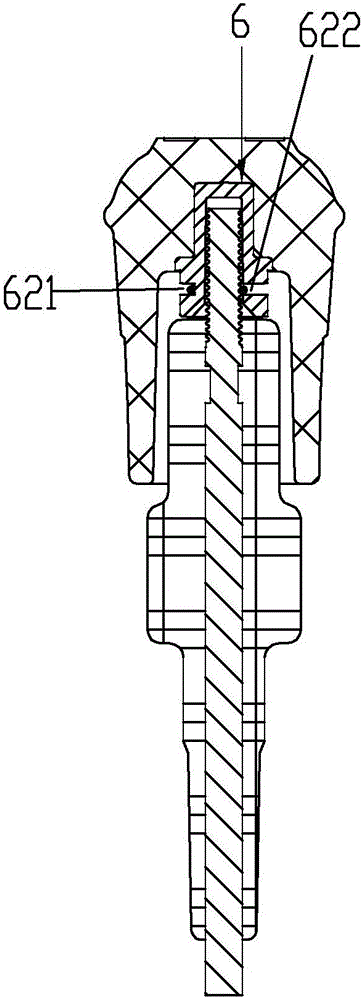

[0016] see figure 2 As shown, the present invention relates to an ignition electrode cap, which includes a shell 8, a connecting pin 4, and a connecting sleeve 6. The two ends of the shell 8 are respectively provided with a high-voltage ignition wire hole 81, an ignition electrode hole 82, a connecting pin 4, and a connecting sleeve 6. The high-voltage ignition wire hole 81 and one end of the ignition electrode hole 82 are correspondingly arranged in the housing 8 respectively. Connected in the ignition electrode hole 82 and electrically connected to one end of the connecting sleeve 6, which also includes a resistor 5, the connecting pin 4 and one end of the connecting sleeve 6 are respectively provided with a first riveting hole 42 and a second riveting hole 61, so The connecting pin 4 and the connecting sleeve 6 are electrically connected to both ends of the resistor 5 through the first riveting hole 42 and the second riveting hole 61 respectively, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com