Low constant speed control method of diesel locomotive

A control method and technology for internal combustion locomotives, applied to electric vehicles, vehicle components, electric braking systems, etc., can solve the problems of poor steady-state accuracy of locomotive speed, large fluctuations in locomotive speed, stop-and-go, etc., and achieve good control accuracy and the effect of speed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

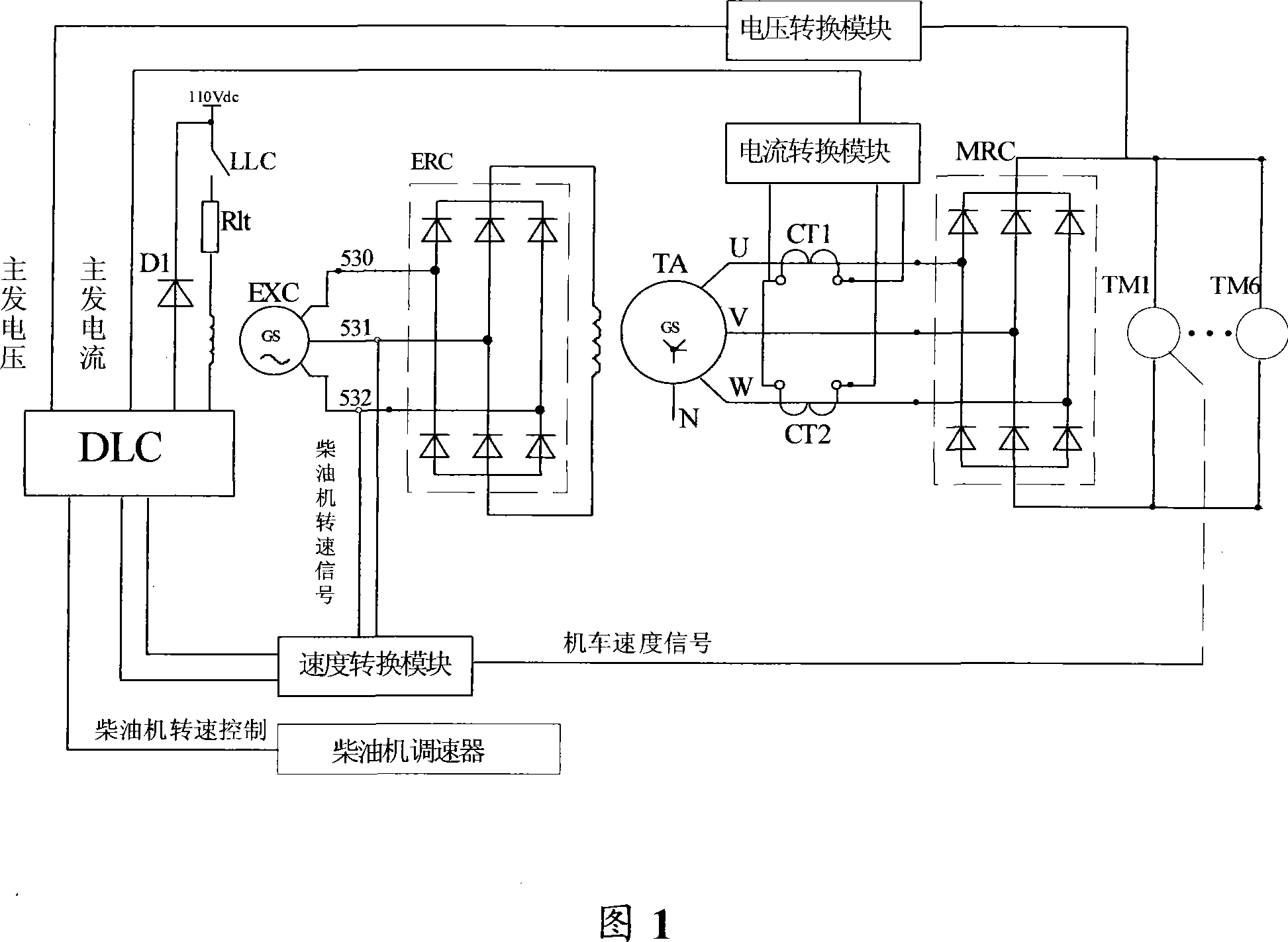

[0021] See attached figure 1 , the system hardware realizing the control method of the present invention is mainly made up of diesel locomotive microcomputer controller DLC and some signal devices. The signal device is a signal conversion device between the microcomputer control system and the locomotive system, including a voltage detection module for the main generator, a current module for detecting the main generator, a voltage transformer isolation module for detecting the speed of the locomotive, etc., which converts the analog signal on the locomotive (including voltage, current) and frequency signals (locomotive speed, diesel engine speed) are isolated and converted to the microcomputer controller DLC, and then the DLC sends the control signal to the exciter EXC and the diesel governor. By adjusting the diesel engine speed and the main generator TA current to achieve low constant speed operation of the locomotive.

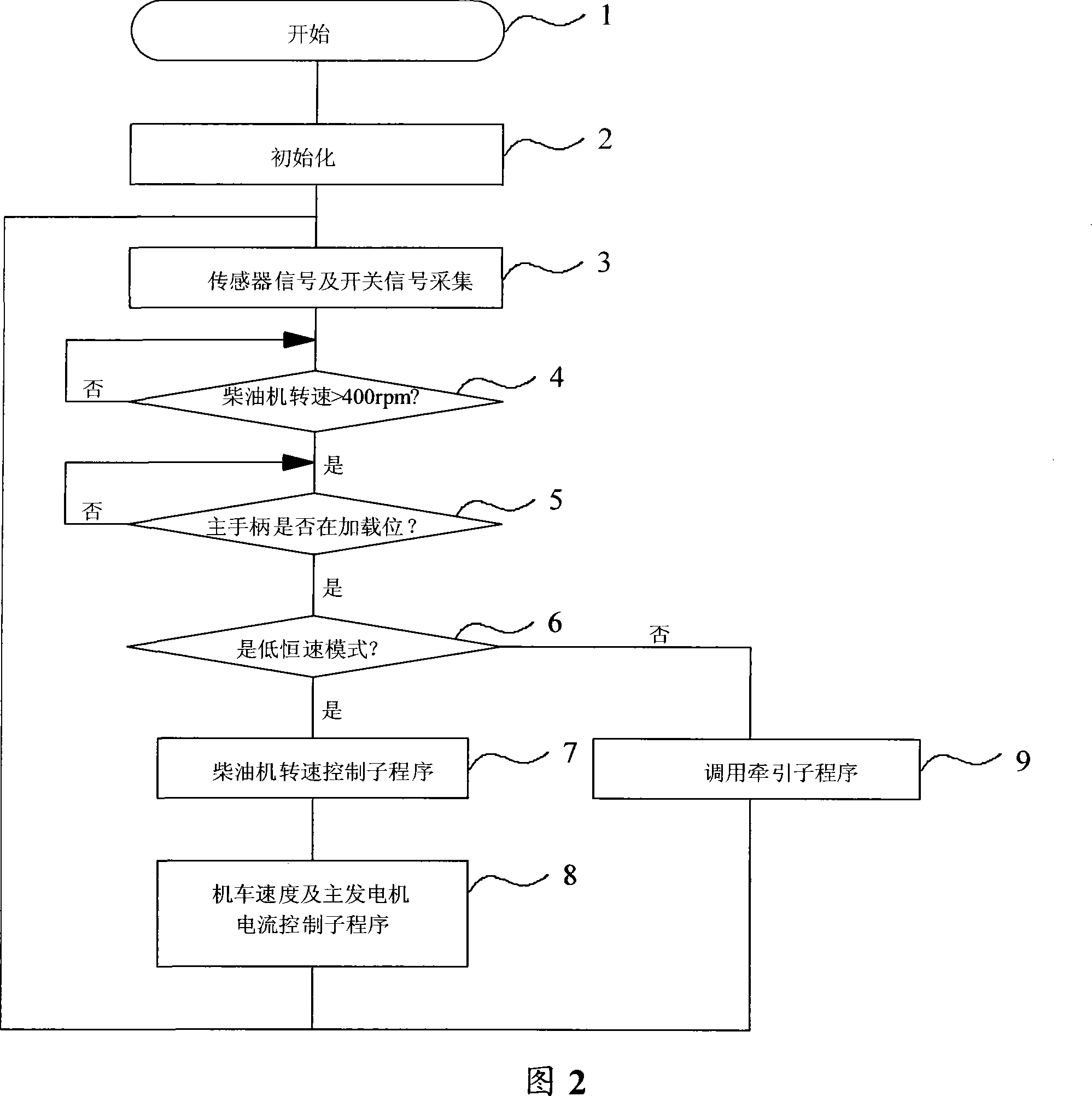

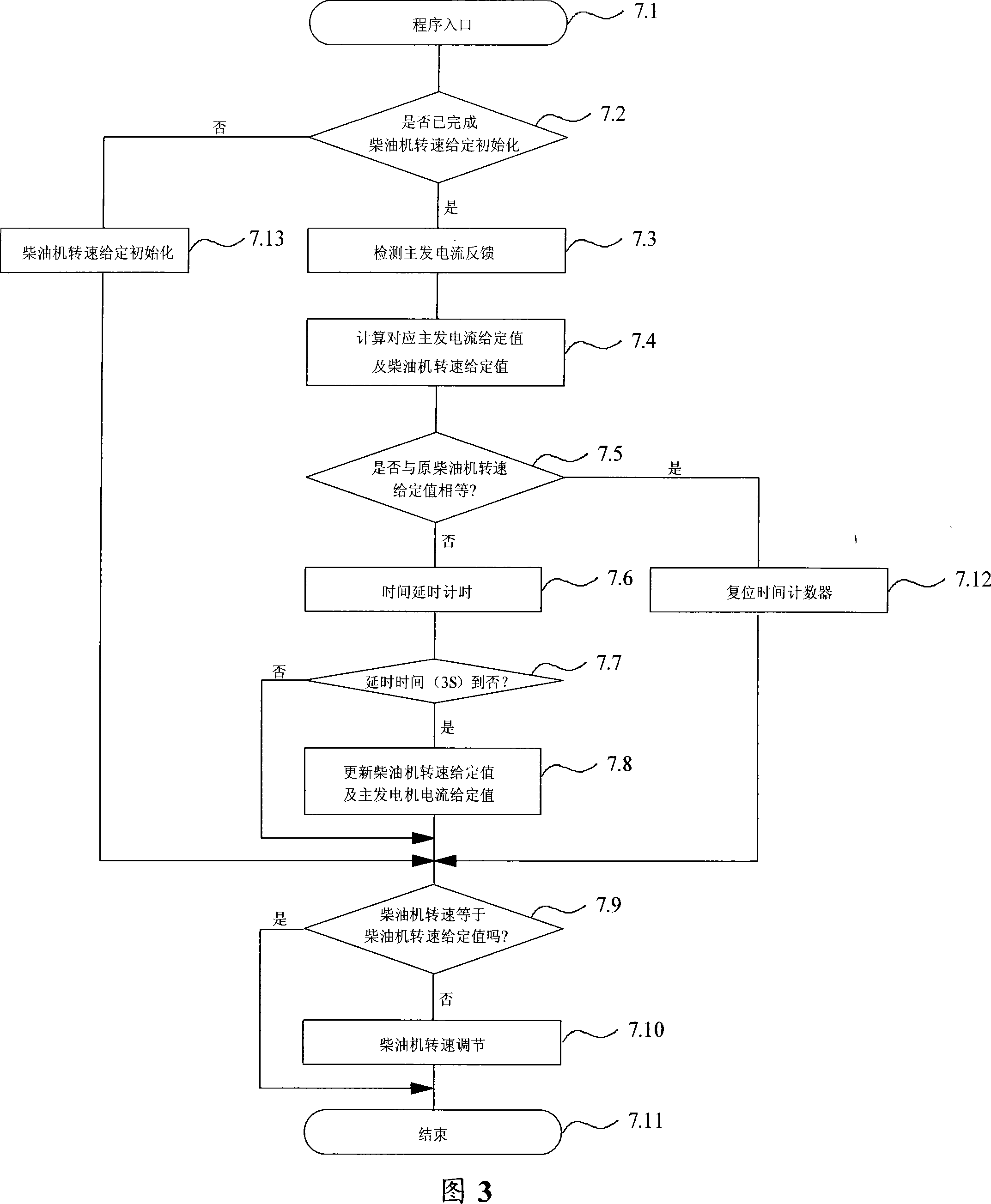

[0022] The steps of the control method in the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com