Weak leakage oil return preventing fuel injection device

A fuel injection device and anti-return technology, which can be applied to fuel injection devices, special fuel injection devices, fuel injection devices with oil reservoirs, etc. cost, the effect of improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

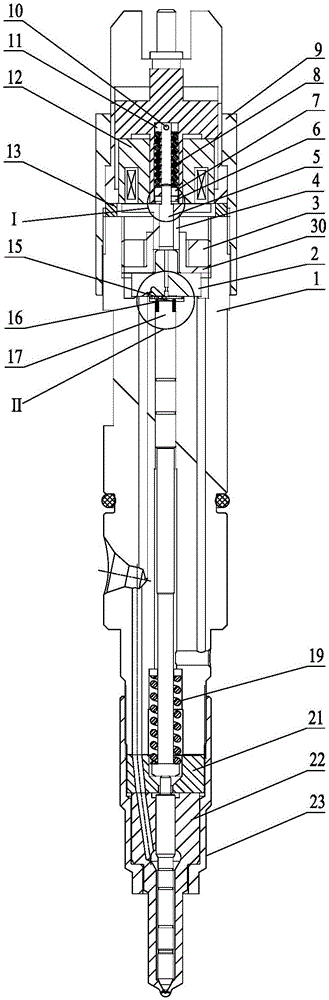

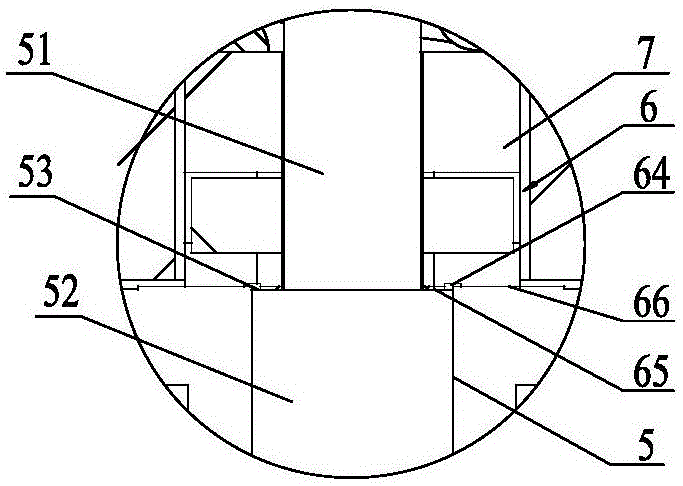

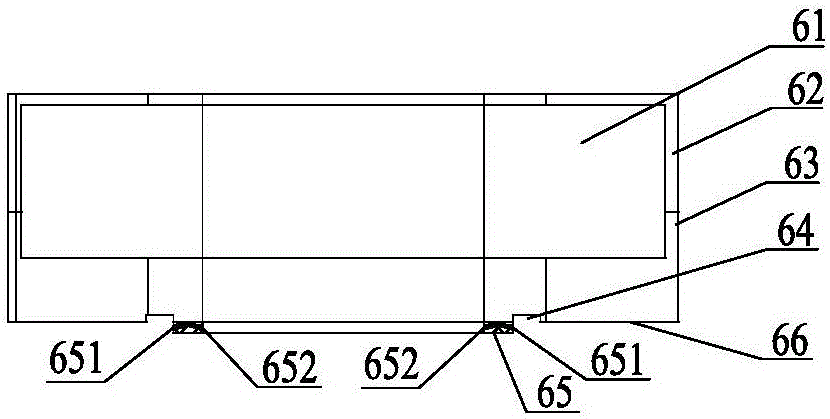

[0029] Such as Figure 1~Figure 6 As shown, the weak leakage anti-return fuel injection device in embodiment 1 is mainly composed of injector body 1, throttle orifice plate 2, control valve seat 3, armature 4, valve core 5, sealing gasket 6, and adjusting gasket 7 , Armature preload spring 8, electromagnet tight cap 9, pin 10, connecting ring 11, electromagnet assembly 12, stroke adjustment ring 13, control panel 15, control panel preload spring 16 control piston 17, preload spring 19, The transition block 21, the oil nozzle coupler 22, the oil nozzle tight cap 23 and the armature guide sleeve 30 etc. are composed.

[0030] The control valve seat 3 is assembled in the upper chamber of the fuel injector body 1 and is threadedly connected with it, and the throttle orifice 2 is fixed between the control valve seat 3 and the fuel injector body 1; the control piston 17 is assembled in the central through hole of the injector body 1, and the upper part of the control piston 17 is m...

Embodiment 2

[0043] Such as Figure 8 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, so the similarities will not be repeated. The difference between embodiment 2 and embodiment 1 is: the weak leakage anti-oil return fuel injection device in embodiment 2 has added a push rod adjusting gasket 18 between the upper end of the pretension spring 19 and the injector body 1; and will implement The control piston 17 in Example 1 is shortened, and a push rod 20 is added between the shortened control piston 17 and the needle valve. On, the lower end of pretension spring 19 is supported on the step.

Embodiment 3

[0045] Such as Figure 9 As shown, the structure of embodiment 3 is basically the same as that of embodiment 2, so the similarities will not be repeated. The difference between embodiment 3 and embodiment 2 is that the weak leakage anti-oil return fuel injection device in embodiment 3 is provided with a return spring 14 between the control valve seat 3 and the armature 4, and the upper part of the control valve seat 3 is provided with An annular valve seat boss 31, the return spring 14 is sleeved on the valve seat boss. In addition, the armature 4 in Embodiment 3 is composed of an armature disc 41 and an armature rod 42, the armature disc 41 is circular, and the upper surface of the armature disc 41 is provided with at least one radial groove 411; the armature rod 42 It is a cylindrical ring, and the armature disk 41 and the armature rod 42 are laser welded as one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com