Bubble-drag-reduction-type marine mining riser

A technology of air bubbles and oceans, applied in the direction of mining minerals, special mining, drilling pipes, etc., can solve the problems of large fluid resistance and large energy consumption, and achieve the reduction of liquid viscosity coefficient, frictional resistance, and fluid frictional resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

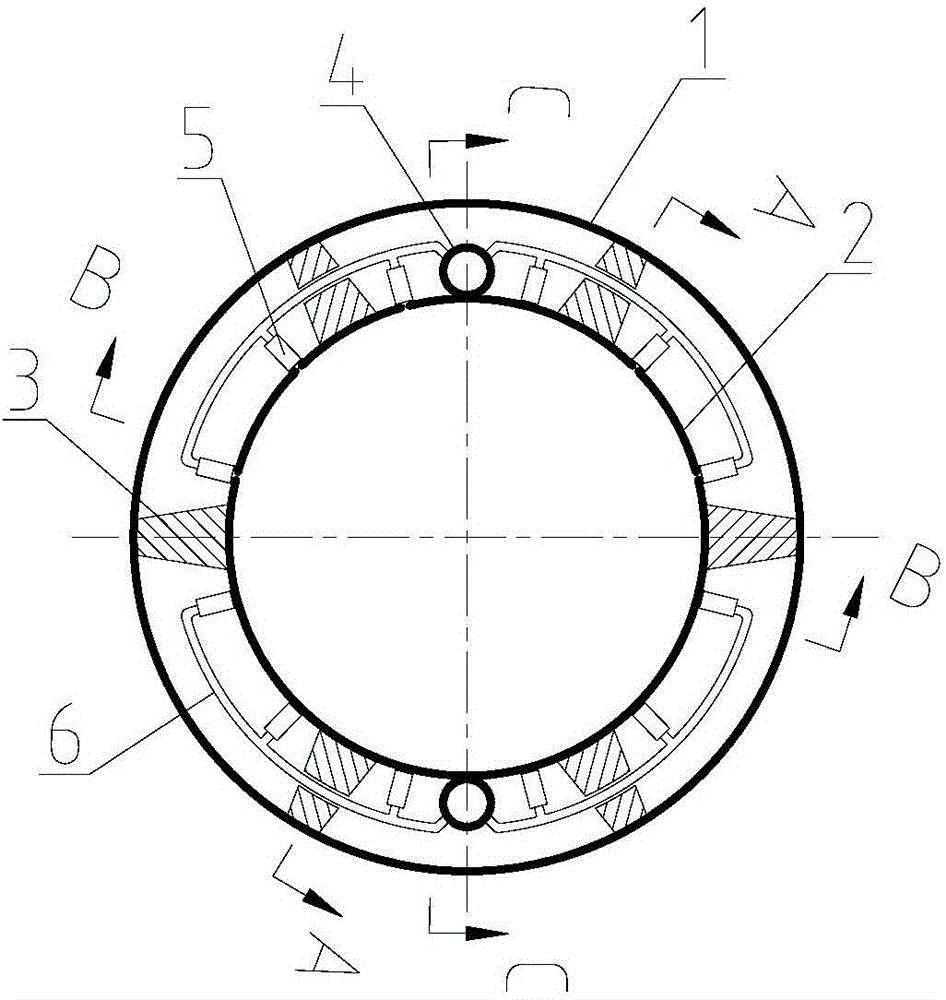

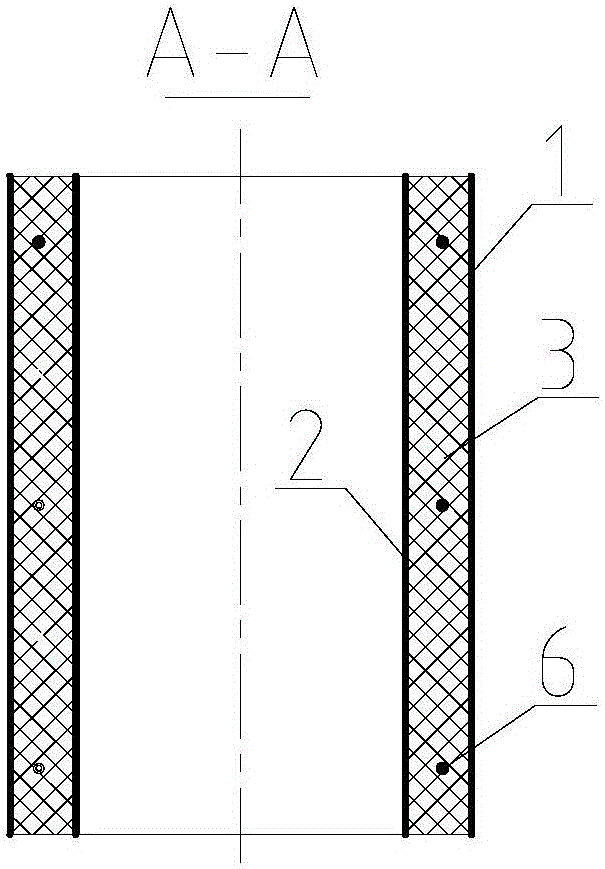

[0022] The present invention provides a marine mining riser for air bubble drag reduction, such as Figure 1 to Figure 4 As shown, it includes an outer tube 1 and an inner tube 2 nested with each other, a main gas delivery pipe 4 arranged between the outer tube 1 and the inner tube 2, a nozzle 5, a gas delivery branch pipe 6 and a support structure 3; the gas delivery There is at least one main pipe 4, which is fixed on the outer wall of the inner pipe 2, and the main pipe 4 for gas transmission is used to connect with the gas supply equipment of the mining ship; the nozzles 5 are evenly distributed along the circumference of the inner pipe 2 to ensure that the air bubbles can cover the inner pipe. The inner wall of the pipe; one end of the nozzle 5 communicates with the inner pipe 2, and the other end of the nozzle communicates with the main gas tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com