Combined pile casing for power transmission tower foundation

A shielding and foundation technology, which is applied in the field of combined shielding, can solve the problems that large-scale equipment is difficult to complete the lifting work, the construction conditions of special engineering pile foundations are poor, and the risk of surface subsidence increases, so as to avoid unstable installation and improve lifting efficiency. , the effect of reducing the difficulty of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

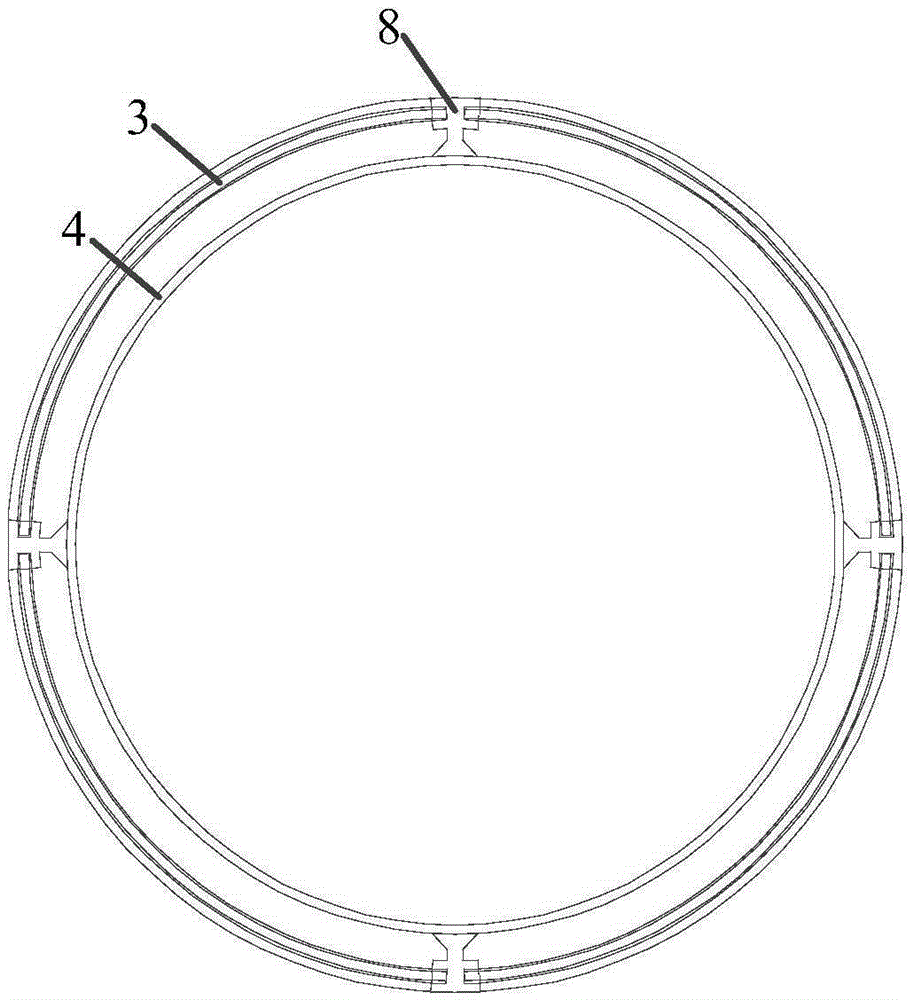

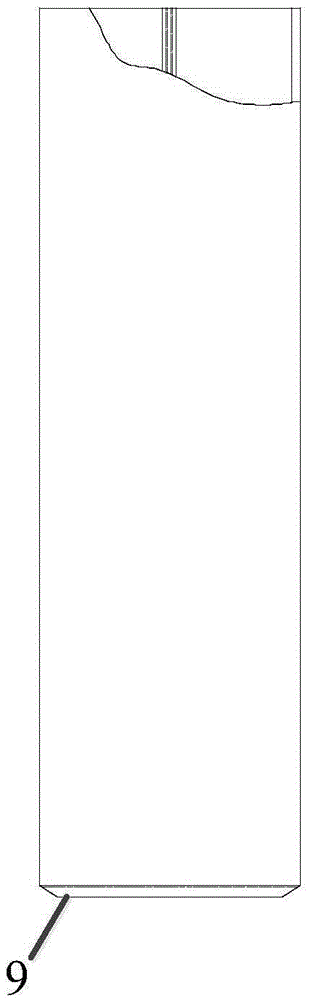

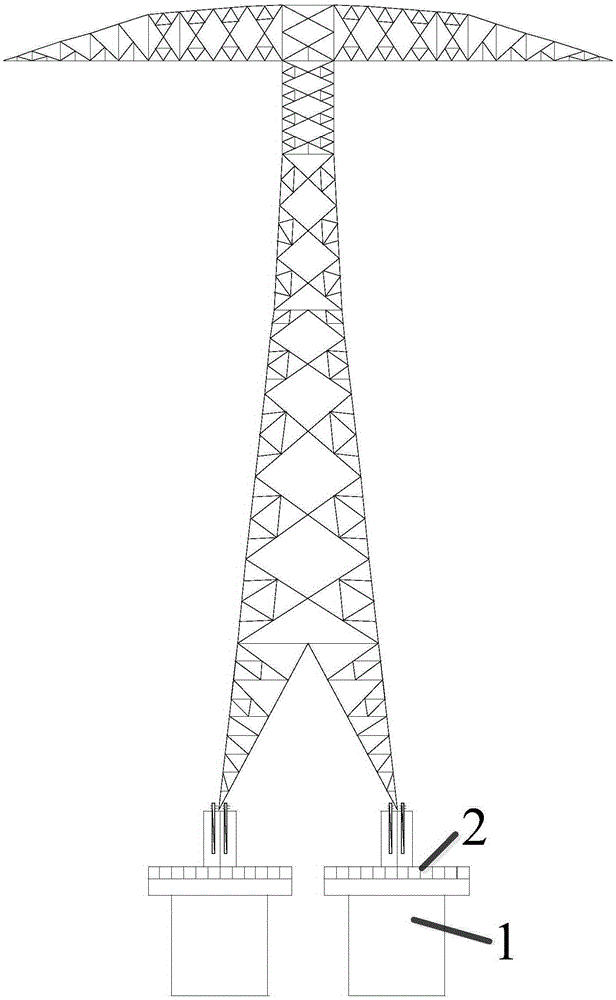

[0042] Such as figure 1 and figure 2 As shown, a combined casing for foundation construction of a transmission tower, the foundation of the transmission tower includes a concrete foundation 1 and a cap 2 arranged on the upper end of the concrete foundation 1, and the composite casing includes an outer steel casing 3 and the inner steel casing 4 socketed in the inner cavity of the outer steel casing 3,

[0043] The upper end of the platform 2 is provided with a fixing assembly 5 for fixing the transmission tower,

[0044] Between the outer steel casing 3 and the inner steel casing 4 , an I-shaped casing connector 8 connecting the casings is arranged in a direction perpendicular to the axis of the composite casing.

[0045] The cap 2 includes a bottom plate 6 and a fixed beam 7 arranged sequentially on the upper end of the concrete foundation 1;

[0046] The bottom plate 6 is a reinforced concrete slab,

[0047] The fixed beam 7 is a reinforced concrete slat arranged transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com