Subsurface drainage ditch bottom hardening structure

A single and cover plate technology, applied in the field of hardened structure at the bottom of the drainage ditch, can solve the problems of difficult engineering, large engineering investment, easy accumulation of water at the bottom of the ditch, etc., and achieve the effect of reducing engineering investment, reducing engineering investment and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

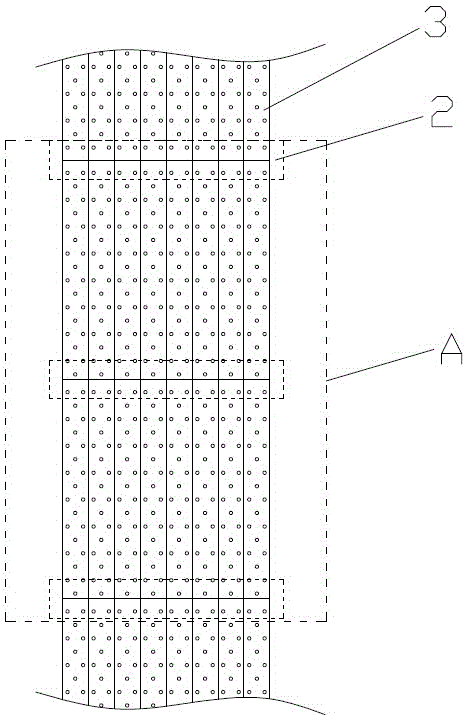

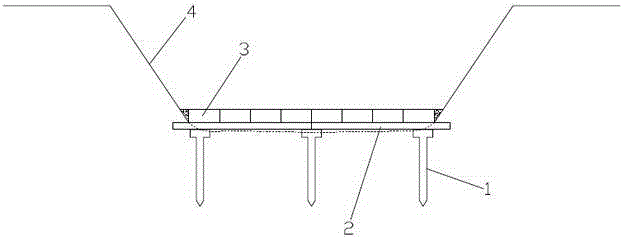

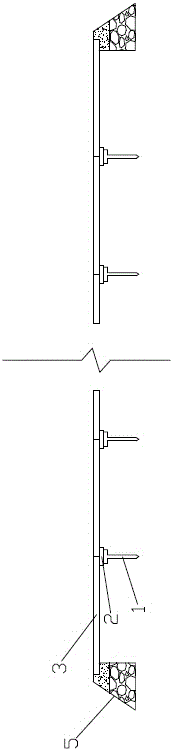

[0025] Such as Figure 1~4 As shown, a hardening structure at the bottom of the drainage ditch includes a bottom hardening device, which is arranged at the bottom of the drainage ditch, and the bottom hardening device includes a T-shaped pile 1, a beam 2, a cover plate 3, and a T-shaped pile 1 Set at the bottom of the drainage ditch, completely inserted into the ground, the top surfaces of multiple T-shaped piles 1 are on the same level, and beams 2 are arranged on multiple T-shaped piles 1, and multiple cover plates are arranged on the beams 2 3.

[0026] The cover plate 3 is a cover plate with through holes.

[0027] Cement mortar is poured in the gap between the cover plate 3 and the slope body 4 .

[0028] Both ends of the bottom hardening device are provided with thrust piers 5 to prevent longitudinal displacement.

[0029] The lower part of the thrust pier 5 is made of masonry rubble, and the upper part of the thrust pier 5 is made of cast-in-place concrete.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com