Swing crease removal textile mechanism

A technology of weaving and frame, applied in the field of oscillating wrinkle-removing textile mechanisms, can solve the problems of unresolved, wrinkled textiles, wrinkled textiles, etc., and achieves the effects of complete functions, improved quality, and promotion of wrinkle removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

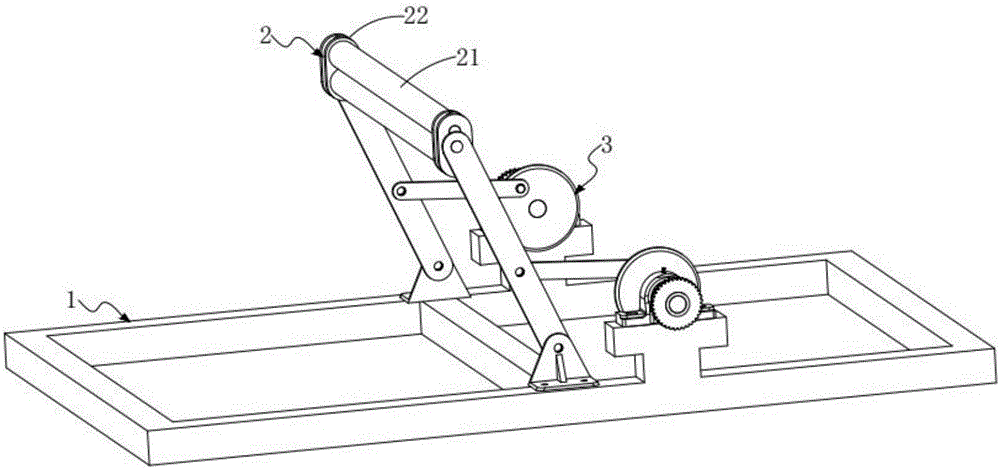

[0030] Such as figure 1 and figure 2 Shown, a kind of swing wrinkle removing textile mechanism comprises:

[0031] Rack 1; and

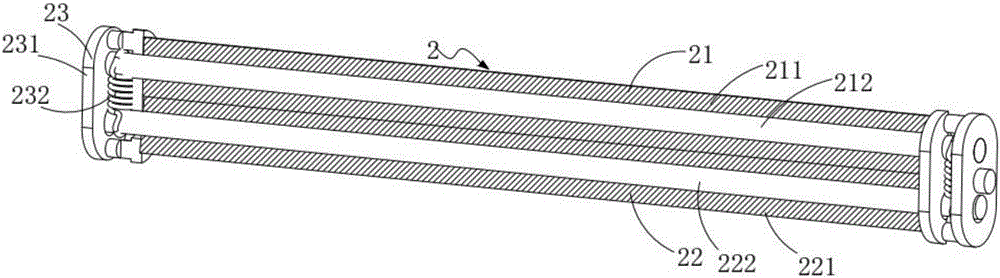

[0032] The wrinkle removal assembly 2, the wrinkle removal assembly 2 is arranged on the top of the frame 1, including an upper wrinkle removal unit 21, a lower wrinkle removal unit 22 and several fixing units 23, and the fixing unit 23 is arranged on the upper wrinkle removal unit 21 and the two ends of the lower wrinkle removal unit 22, and the upper wrinkle removal unit 21 is arranged above the lower wrinkle removal unit 22 and arranged tangentially and parallel to it;

[0033] A plurality of swing assemblies 3, the swing assemblies 3 are arranged at both ends of the wrinkle removal assembly 2, including a rotation unit 31 and a swing unit 32, the rotation unit 31 is fixedly arranged on the frame 1, one end of the swing unit 32 The rotating unit 31 is hinged, and the other end is hinged to the fixing unit 23 .

[0034] It should be noted that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com