Quenching robot

A robot and quenching tank technology, applied in the field of heat treatment, can solve the problems of large dimensional changes and easy deformation, and achieve the effect of changing the cooling speed, reducing labor intensity and stabilizing the quality of quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

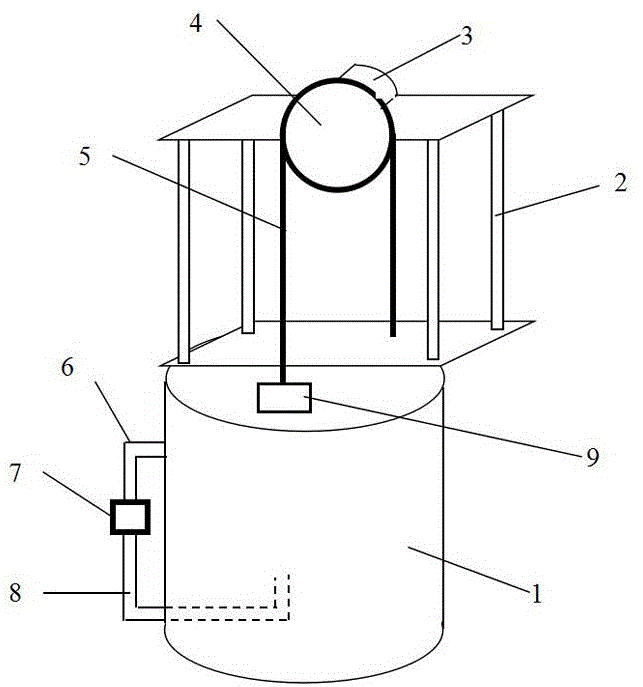

[0014] Such as figure 1 Shown: a kind of quenching robot, comprises the quenching tank 1 that is used to store quenching medium and a lifting mechanism that is used to drive quenched workpiece 9 lifting, the upper end opening of described quenching tank 1 is provided with, and quenching tank 1 is also provided with The inlet pipe 6 and the outlet pipe 8, the outlet pipe 8 is located below the inlet pipe 6, and a pipeline booster pump 7 for pressurizing the quenching medium is arranged between the outlet pipe 8 and the inlet pipe 6, and the lifting mechanism passes through the bracket 2 Set on one side of the quenching tank 1, the lifting mechanism includes a motor 3, a sprocket 4 connected to the output end of the motor 3 and a chain 5 matched with the sprocket 4, one end of the chain 5 is the connection end of the workpiece to be quenched, and the other end of the chain 5 for the free end.

Embodiment 2

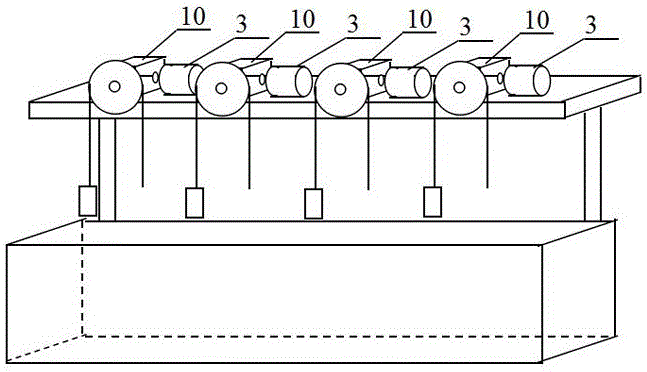

[0016] Such as figure 2 Shown: a quenching robot, including a quenching tank 1 for storing quenching medium and four lifting mechanisms for driving the quenched workpiece 9 to lift, the upper end of the quenching tank 1 is open, and the quenching tank 1 is also set There are an inlet pipe 6 and an outlet pipe 8, the outlet pipe 8 is located below the inlet pipe 6, and a pipeline booster pump 7 for pressurizing the quenching medium is arranged between the outlet pipe 8 and the inlet pipe 6, and the lifting mechanism passes through the bracket 2 Set on one side of the quenching tank 1, the lifting mechanism includes a motor 3, a sprocket 4 connected to the output end of the motor 3 and a chain 5 matching with the sprocket 4, and a reducer is arranged between the sprocket 4 and the output shaft of the motor 3 10. One end of the chain 5 is the connection end of the workpiece to be quenched, and the other end of the chain 5 is the free end.

[0017] The quenching robot of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com