Turpentine rectification tower vacuum system

A technology of vacuum system and turpentine, applied in the field of vacuum system, can solve the problems of easy damage of vacuum pump, lower product yield, unstable vacuum degree, etc., and achieve the effects of reducing environmental pollution, low cost and stable vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

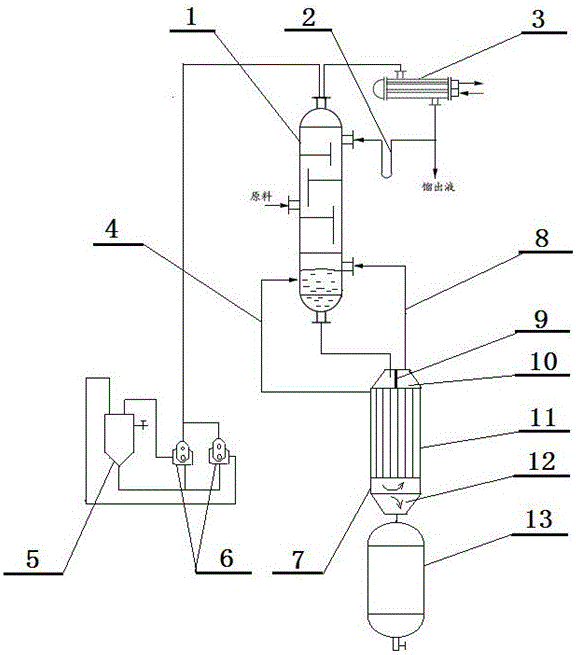

[0026] as attached figure 1 As shown, the vacuum system of the turpentine rectification tower includes a rectification tower 1, a condenser 3, a water ring vacuum pump 6 and a reboiler 7; the outlet of the rectification tower 1 top and the condenser 3 Connected, the bottom of the rectification tower is connected with the feed port at the top of the reboiler 7, the bottom of the reboiler 7 is connected with a waste liquid storage tank 13, the water ring vacuum pump 6 is connected with the top of the rectification tower 1 Connected, the water ring vacuum pump 6 is also connected with the oil-water separator 5.

[0027] Further, two water ring vacuum pumps 6 are arranged in parallel.

[0028] Further, the feed inlet of the rectification tower 1 is located in the middle section of the rectification tower 1 . The packing in the rectifying tower 1 is corrugated packing of stainless steel wire mesh.

[0029] Further, the reboiler 7 is a tube-and-tube reboiler, which includes a tan...

Embodiment 2

[0034] In this embodiment, one water ring vacuum pump 6 is provided, and the rest of the settings are the same as those in Embodiment 1.

[0035] Slash pine turpentine (62.17% α-pinene content and 26.45% β-pinene content in turpentine oil) is preheated to 100°C in the raw material storage tank and sent to the rectification tower through the feed pump, and the water ring vacuum pump is started. The turpentine oil enters the vacuum tube and reaches the water ring vacuum pump. Through the water circulation of the water ring vacuum pump water pipe, it reaches the oil-water separator. Since the turpentine oil is lighter than water, it can be recovered at the recovery port of the oil-water separator after oil-water separation. During the rectification process, the vacuum degree of the control system is -0.09MPa, and the α-pinene gas is isolated at a reflux ratio of 10:1, and the α-pinene gas passes through the condenser separately, and the condensed distillate is detected to meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com