Feeding mechanism for machine tool

A technology of feeding mechanism and machine tool, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of reducing production efficiency, damage and slipping of aluminum ingot materials, and achieve the effect of improving feeding efficiency, reducing load capacity and uniform efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

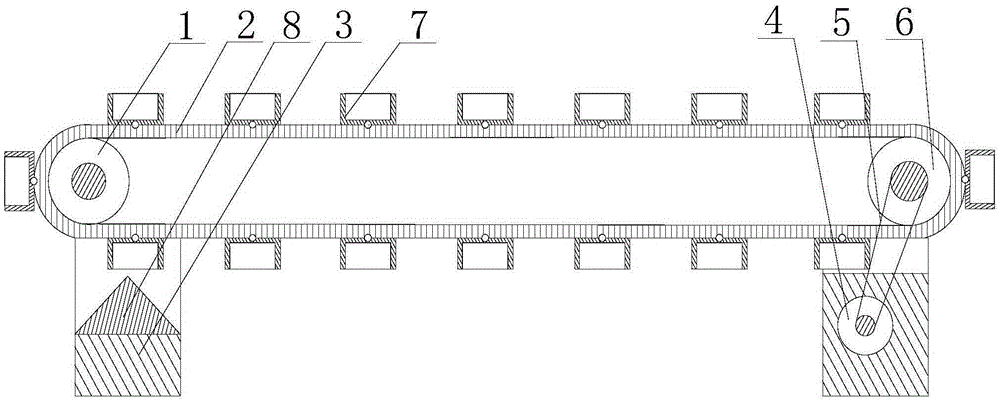

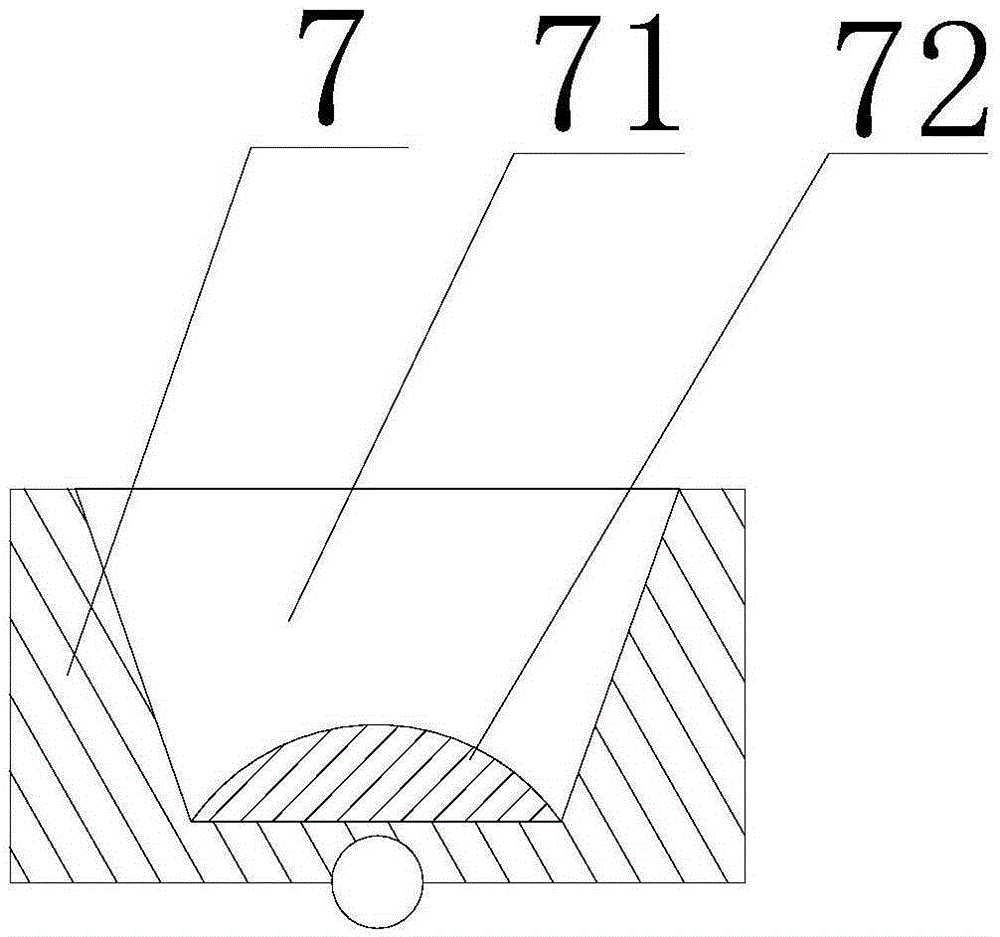

[0020] Such as figure 1 and figure 2 As shown, the present embodiment includes two U-shaped support bases 3 arranged at intervals and a transmission chain plate 2, the main roller 6 and the slave roller 1 are respectively rotated and arranged on the two support bases 3, and the two ends of the transmission chain plate 2 Placed in the U-shaped area of the support seat 3 and matched with the main roller 6 and the slave roller 1, the conveying chain plate 2 is hingedly provided with a plurality of hoppers 7 whose interior matches the shape of the aluminum ingot, and also includes Motor 4, the motor 4 is placed at the bottom of the support seat 3 and its output end is connected and matched with the rotating shaft of the main roller 6 through the belt 5; a collection block 8 is installed at the bottom of the U-shaped area of the support seat 3 corresponding to the slave roller 1 , the upper end of the collection block 8 is composed of two interconnected inclined surfaces, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com