Plastic bucket and plastic bucket feeding, discharging and conveying system

A conveying system and glue hopper technology, which is applied to conveyors, conveyor objects, packaging, etc., can solve problems such as the inability to achieve variable speed requirements, the inability to adjust the cylinder speed, and the impact on production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

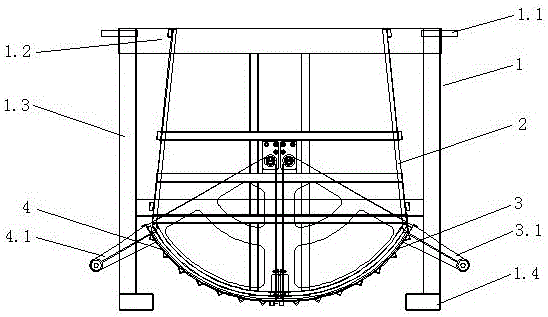

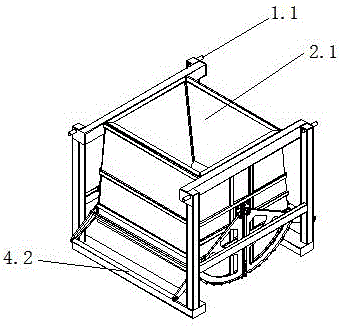

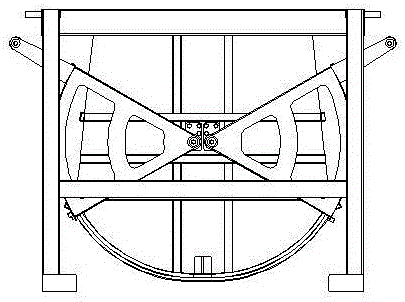

[0028] see Figure 1-Figure 3 , an embodiment of a glue hopper of the present invention, including a bucket body 2, on which the bucket body 2 is provided with a feed inlet, a discharge outlet and a discharge door. The bucket body 2 is arranged in the middle of a frame-shaped base 1, the upper part of the frame-shaped base 1 is provided with a hanger that cooperates with the aerial conveying line, and the bottom of the frame-shaped base 1 is provided with a supporting part that cooperates with the ground conveying line 18. The material opening 2.1 is arranged on the top of the bucket body 2, and the discharge opening is arranged on the bottom of the bucket body 2.

[0029] Specifically: the above-mentioned frame-shaped base 1 is a square frame, including 4 parallel and vertically arranged columns 1.3 and two beams 1.2, the connection line of the upper ends of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com