Automatic detection and air filling and degassing system of tire pressure and method for detecting air filling and degassing thereof

An automatic detection, inflation and deflation technology, applied in the field of tire inflation and deflation, can solve the problems of large memory usage, errors, and large system calculation, and achieve the effects of strong anti-interference ability, low tire blowout rate, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

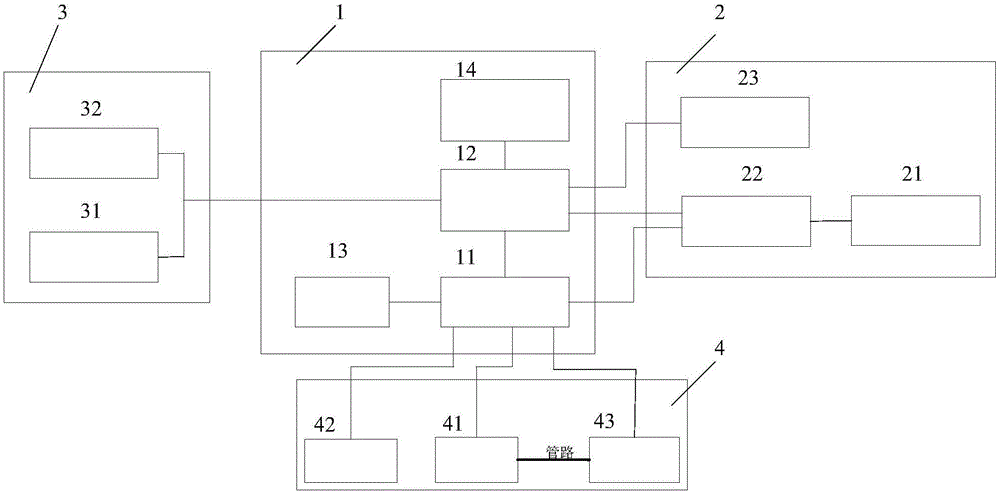

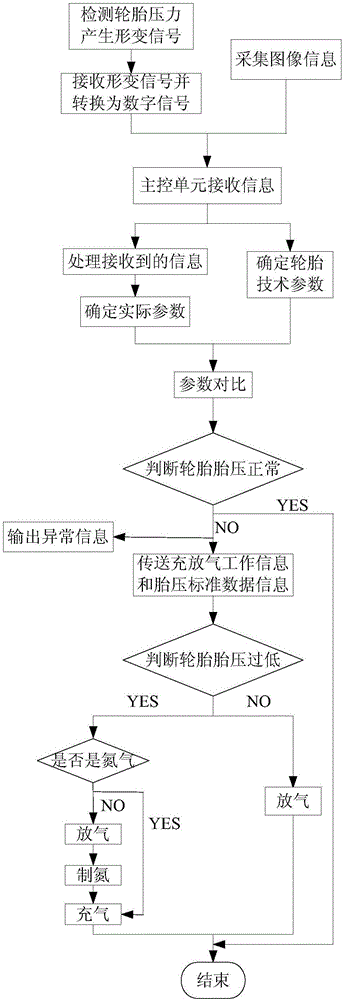

[0071] Such as figure 1 As shown, the system is set in the tire pressure detection area, including a main control unit 1, a detection unit 2, an output unit 3 and an inflation and deflation unit 4;

[0072] The detection unit 2 includes: a sensor 21, a signal conversion device 22 and an image signal acquisition device 23,

[0073] One or more sensors 21 are evenly arranged on the ground, used to sense tire pressure and generate deformation signals;

[0074] The signal conversion device 22 receives the deformation signal of the sensor 21 and converts it into a digital signal and an analog signal;

[0075] The image signal collection device 23 is used to collect the image information of the brand, type and model of the vehicle;

[0076] The main control unit 1 includes: a programmable controller 11, an industrial computer 12, an industrial computer display screen 14 and an input device 13,

[0077] The programmable controller 11 receives the deformation signal of the signal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com