Embossing and perfume spraying device for toilet paper

A toilet paper and embossing technology, which is applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of low energy utilization rate, excessive use of equipment, complex structure, etc., and achieve high energy utilization rate, less equipment use, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

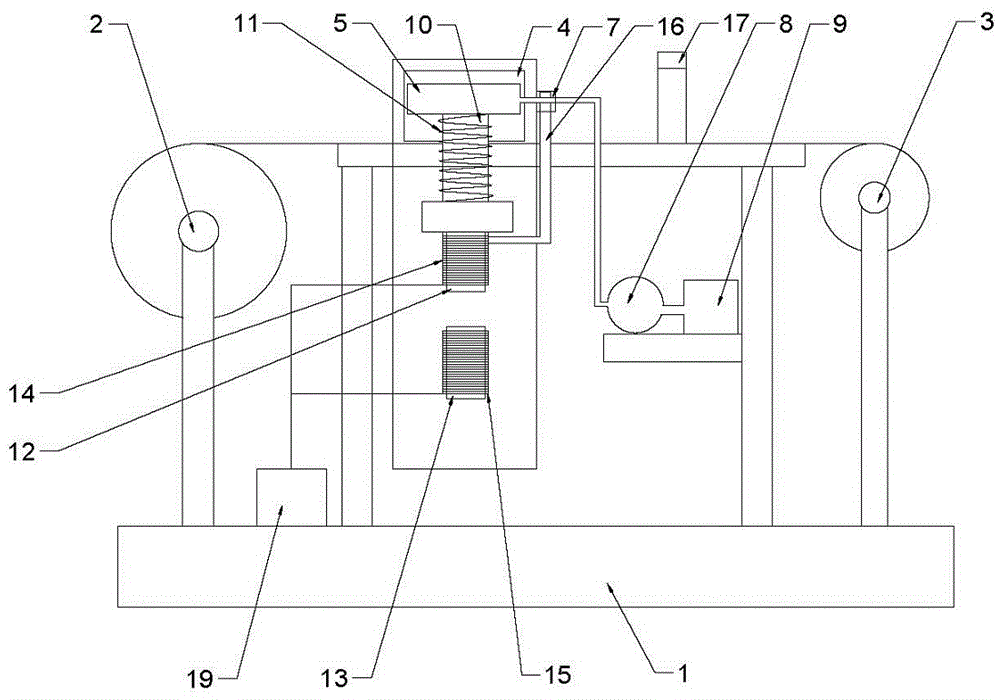

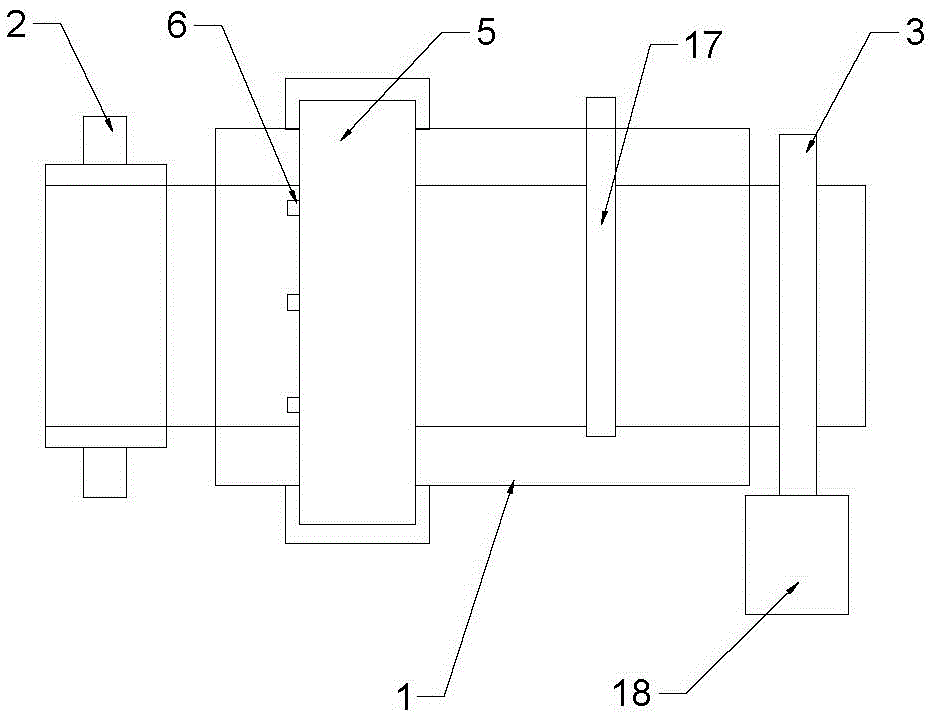

[0019] The reference signs in the drawings of the description include: frame 1, first roller 2, second roller 3, chute 4, embossed plate 5, atomizing nozzle 6, valve 7, pressure pump 8, liquid storage tank 9. Pull rod 10, compression spring 11, upper iron column 12, lower iron column 13, first conductive coil 14, second conductive coil 15, connecting rod 16, heating lamp tube 17, stepper motor 18, pulse power supply 19.

[0020] Example basic reference figure 1 and figure 2 Shown: toilet paper embossing and fragrance spraying device, including a frame 1 and three atomizing nozzles 6, the left and right ends of the frame 1 are rotatably connected with a first roller 2 and a second roller 3, and the ends of the second roller 3 A stepper motor 18 is fixedly connected, and a symmetrical chute 4 is opened on the vertical direction of the frame 1, and an embossed plate 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com