Bellows universal tractor

A technology of tractor and bellows, which is applied in the field of general tractors for bellows, can solve problems such as cumbersome operation, and achieve the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

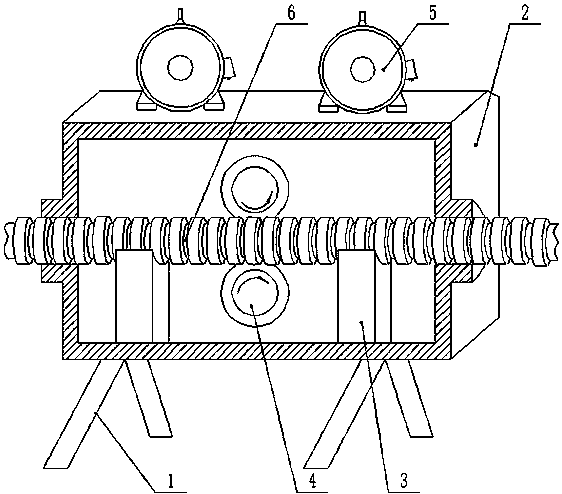

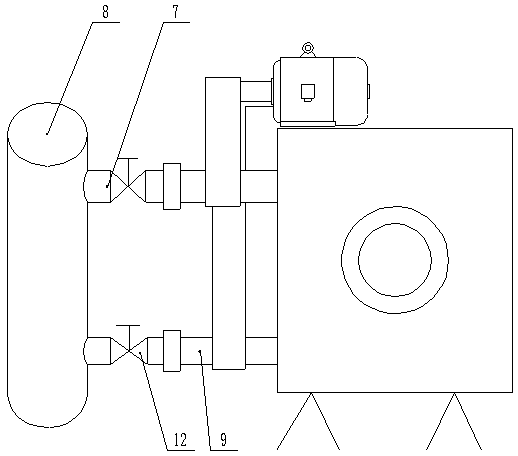

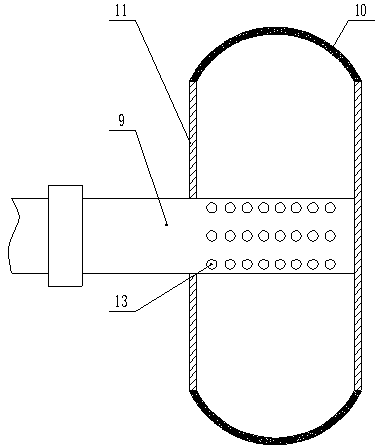

[0016] Description of reference numerals: bracket 1, transmission box 2, support column 3, drive wheel 4, drive motor 5, bellows 6, air pipe 7, inflator 8, drive shaft 9, air bag layer 10, support circular plate 11, air Regulating valve 12, air hole 13.

[0017] Such as figure 1 with figure 2 The shown bellows universal tractor includes a bracket 1 and a transmission box 2, the transmission box 2 is installed on the frame 1, the left and right ends of the transmission box 2 are provided with openings for the bellows 6 to pass in and out, and the transmission box Two support columns 3 are installed at the bottom of the 2, and the top surface of the support columns 3 is an arc surface. The corrugated pipe 6 enters from the opening at the left end of the transmission box 2, passes through the top surface of the support column 3 in the transmission box 2, and then passes out from the right opening of the transmission box 2. Two driving wheels 4 are installed between the two su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com