Linear cutting slope oscillating bar wire arraying mechanism and linear cutting machine tool

A wire cutting slope and wire cutting technology, applied in metal processing equipment, manufacturing tools, electric processing equipment, etc., can solve the problems of single working mode, the angle of the working section of the electrode wire cannot be changed and adjusted, etc., to achieve the effect of convenient cutting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

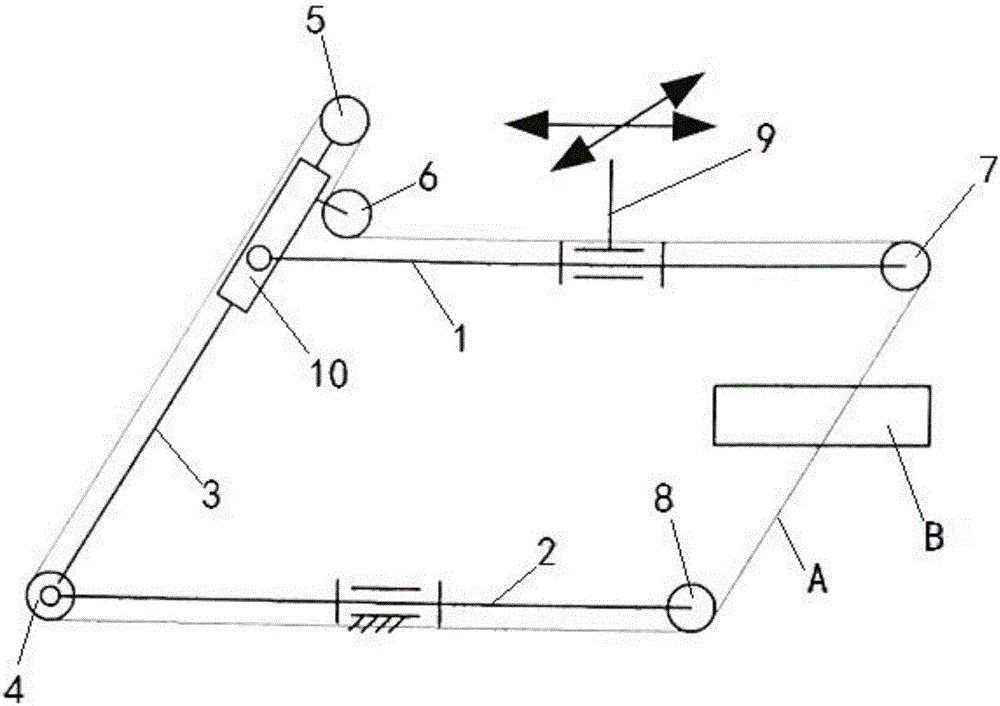

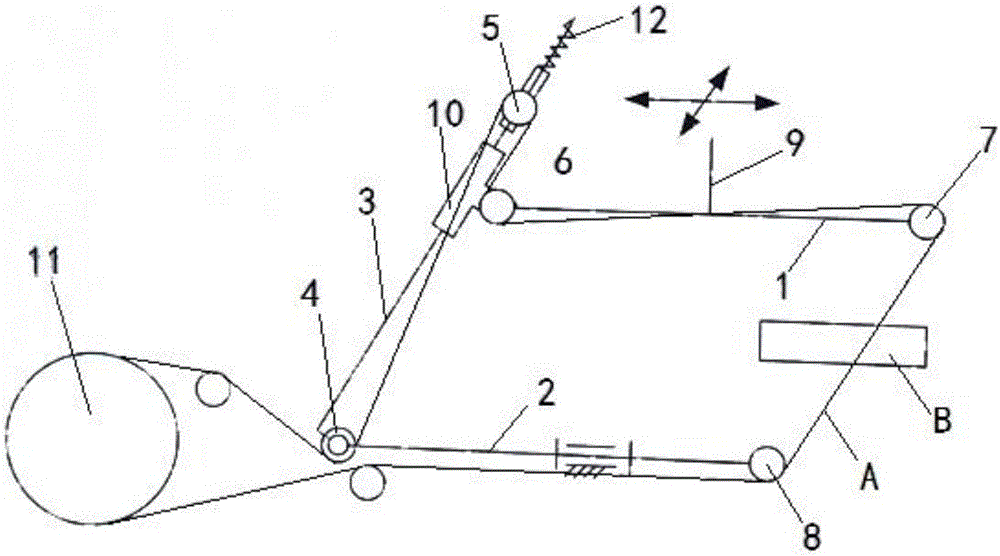

[0030] figure 2 It shows a specific embodiment of the application of the wire-cutting slope swing rod wire-discharging mechanism of the present invention on a wire-cutting machine tool. The mechanism mainly includes a base frame (not shown in the figure), an upper arm 1, a lower arm 2, and a sliding sleeve 10, pendulum bar 3, the first row of silk wheels 4, the second row of silk wheels 5, the third row of silk wheels 6, the fourth row of silk wheels 7 and the fifth row of silk wheels 8. in:

[0031] In actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com