Novel flange end face boring bevelling machine

A beveling machine and end face technology, which is used in boring/drilling, large fixed members, metal processing machinery parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

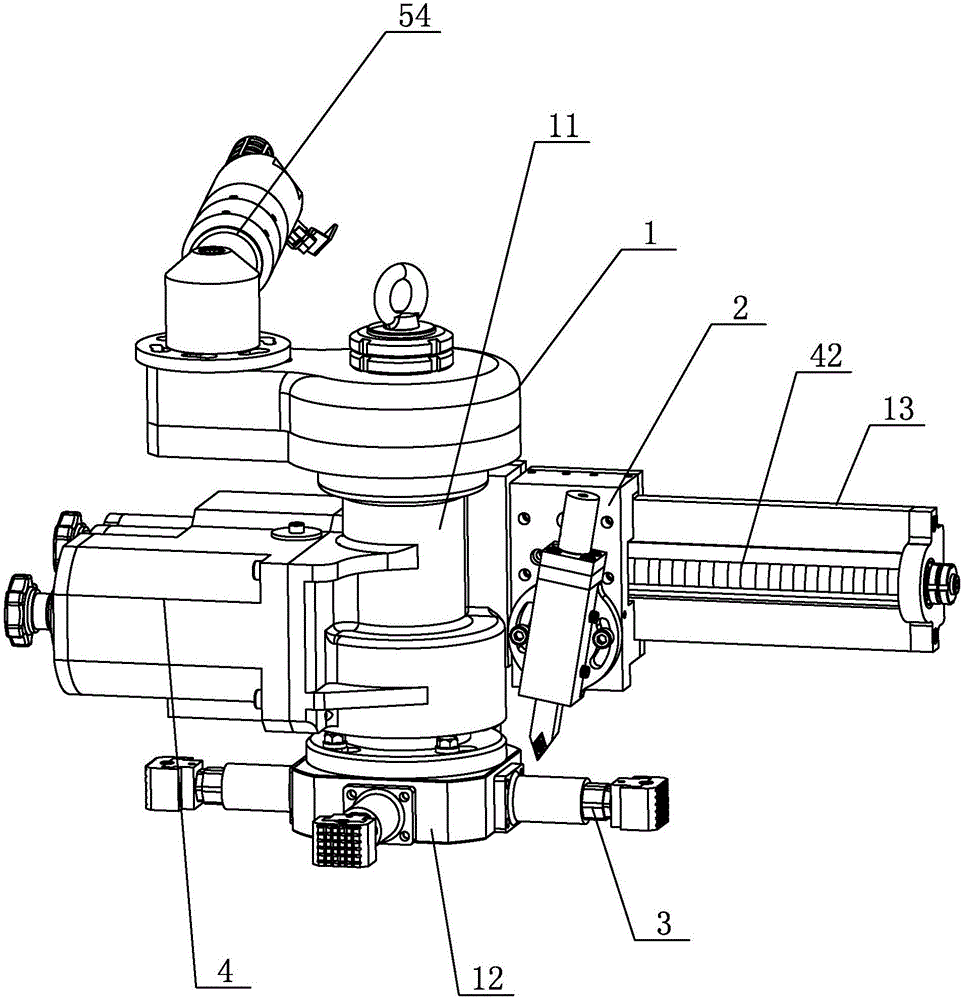

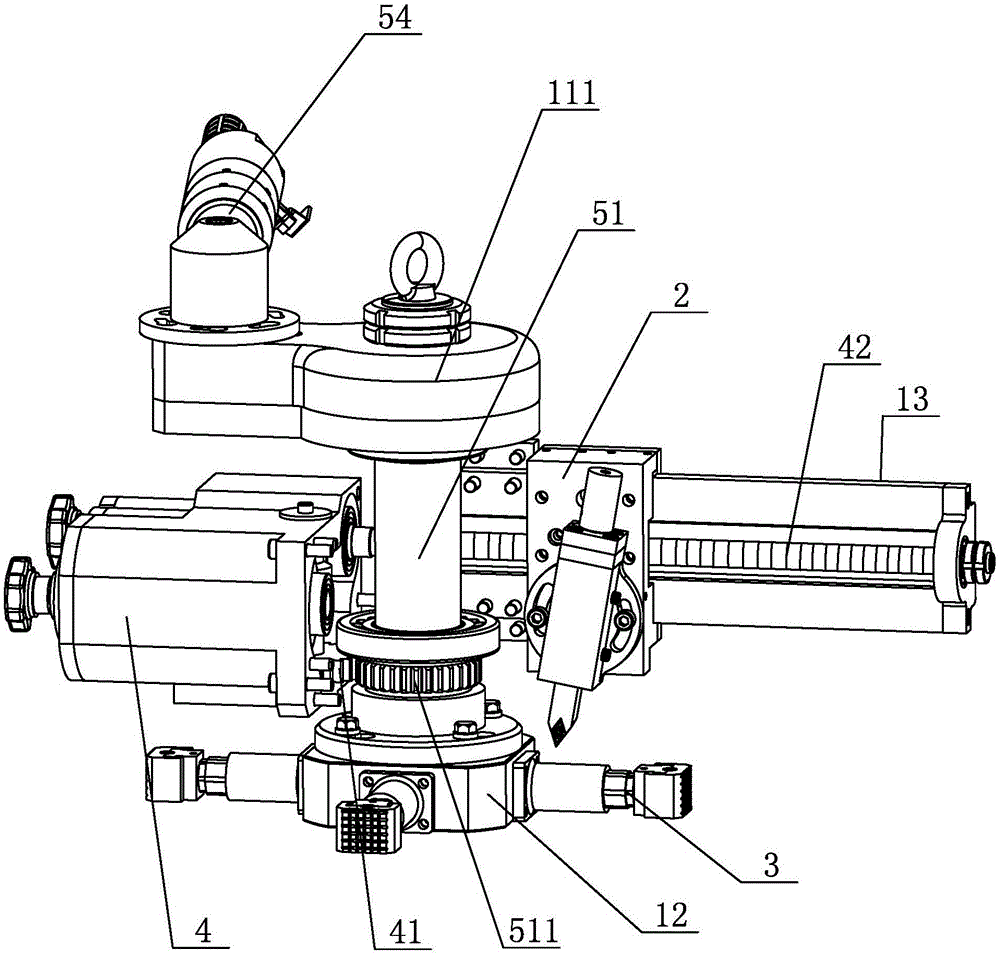

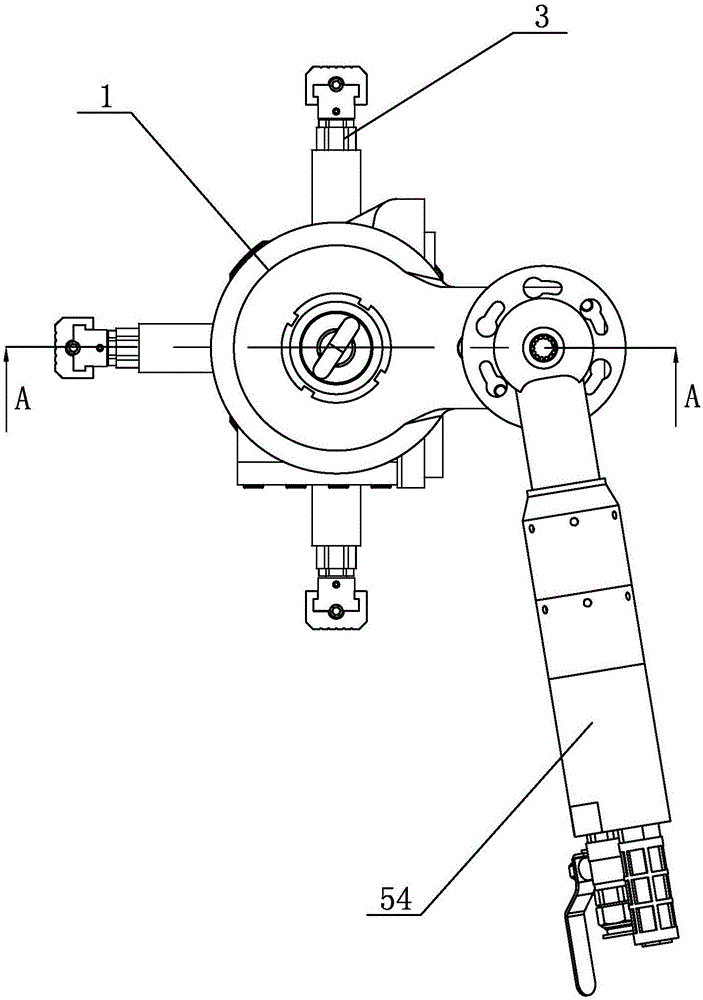

[0043] Such as Figure 1-17 As shown, a new type of flange end face boring and beveling machine includes a body 1 on which a tool mounting frame 2, a tensioning mechanism 3 and a drive device 4 for advancing and retreating the knife are arranged. The body 1 includes an upper machine base 11 and a tensioning The base 12, the advance and retreat knife transmission device 4 are arranged on the upper machine base 11, the tensioning mechanism 3 is arranged on the tensioning base 12, the body 1 is fixedly provided with a mounting bracket 13, and the tool mounting frame 2 is slidably arranged on the mounting bracket 13, the tool mounting frame 2 is provided with a tool 21, the tool 21 can be adjusted to adjust the angle, the upper base 11 is rotatably arranged on the tension base 12, and the advancing and retreating drive device 4 includes a variable speed drive gear 41 and a tool advancing To the screw rod 42, the variable speed drive gear 41 drives the cutter feed screw rod 42 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com