Auxiliary power system with direct-current frequency converter and direct-current variable-frequency motor

A technology of DC frequency converter and factory power system, applied in the direction of DC motor speed/torque control, AC motor control, control system, etc., can solve the problems of low motor operation efficiency, high investment cost of frequency converter, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

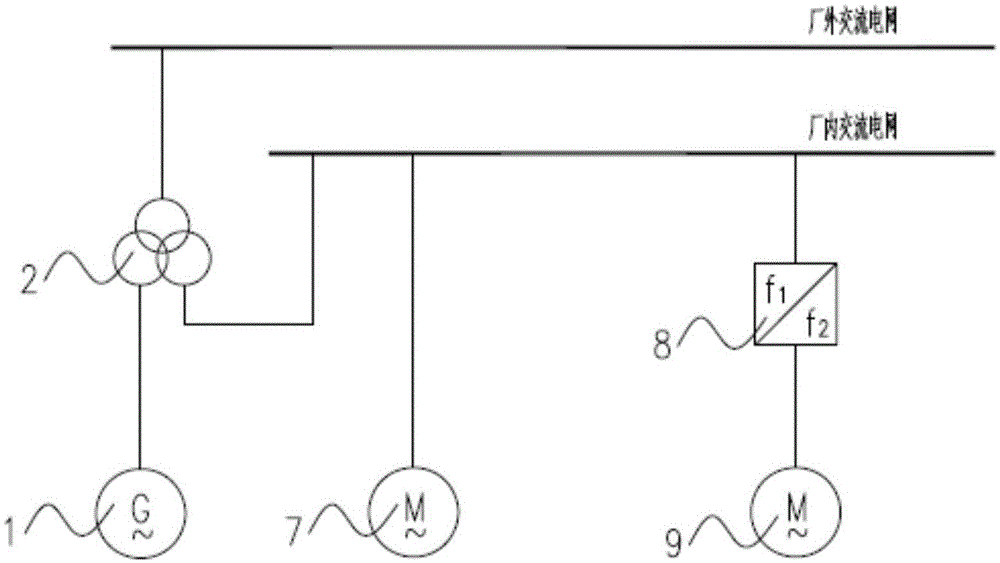

Embodiment 1

[0114] The electricity generated by the AC generator set is transformed by the AC transformer and then sent to the AC power grid outside the factory and inside the factory. The AC power grid in the factory supplies power to the motors of various equipment in the factory. Among them, the AC power frequency motor with higher power can directly use the power frequency AC power provided by the AC power grid in the factory. The DC variable frequency motor needs the help of AC / DC converter or transformer and DC frequency converter. First, the AC / DC converter converts the plant's AC power to the plant's DC power. Secondly, the DC frequency converter converts the DC power in the factory into DC frequency conversion power, which is used to drive the DC frequency conversion motor.

[0115] In this system, both the AC / DC converter and the DC frequency converter are public equipment, and multiple DC variable frequency motors can be connected at the same time, without the need for one-to...

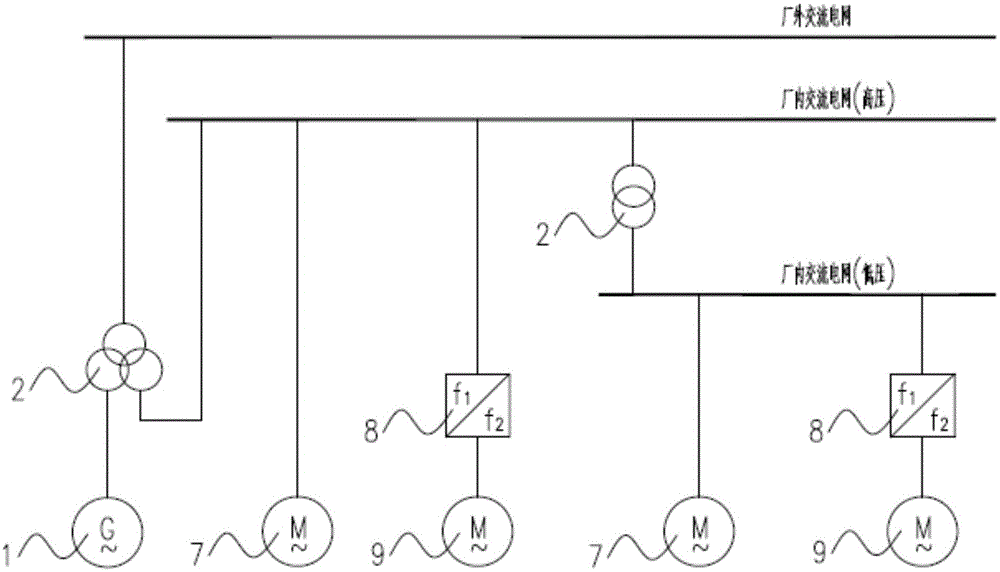

Embodiment 2

[0117] Figure 4 The proposed scheme and image 3 The basic principle of the scheme is the same, the difference is that for equipment motors operating under low-voltage conditions, an AC transformer is added as needed to provide low-voltage in-plant AC power frequency. Low-voltage in-factory AC power can supply power to AC power-frequency motors, and can also be converted into low-voltage in-factory DC power through AC / DC converters, and then supplied to DC variable-frequency motors after frequency conversion by DC converters. and image 3 similar, Figure 4 The converters and DC frequency converters on the medium, high and low voltage sides are common, and can drive multiple DC variable frequency motors at the same time.

[0118] and figure 2 compared to, Figure 4 The electrical system shown is obviously simplified, the system energy loss is also greatly reduced, and the power supply economy is obviously improved.

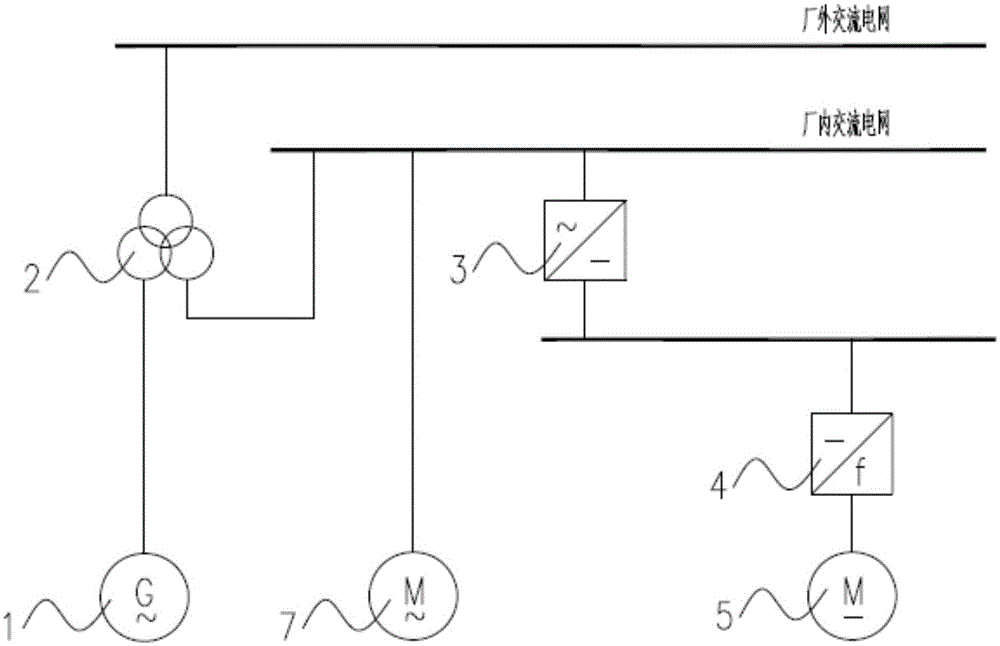

Embodiment 3

[0120] Figure 5 The schemes shown are image 3 The basic principles of the scheme are the same, the difference is that Figure 5 The AC frequency conversion motor is still retained in the factory, and this part of the motor still uses the AC frequency conversion system, that is, the AC frequency converter in the factory is still converted into AC frequency conversion power, and the AC frequency conversion power is used to drive the AC frequency conversion motor.

[0121] This plant power system scheme integrates the AC frequency conversion plant power system and the DC frequency conversion plant power system, which provides energy-saving space for the existing AC frequency conversion plant power system. For the built AC variable frequency plant power system, it is possible to retain part of the AC variable frequency motor to reduce the cost of transformation, and to improve the efficiency and economy of the plant power system to meet the requirements of energy saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com