Recovery unit for concrete block cutting process

A technology of concrete block and recycling device, which is applied to the removal of solid waste and other directions, can solve the problems of high cost of the device and increased workload of the waste storage tank inlet, and achieve the effect of reducing the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

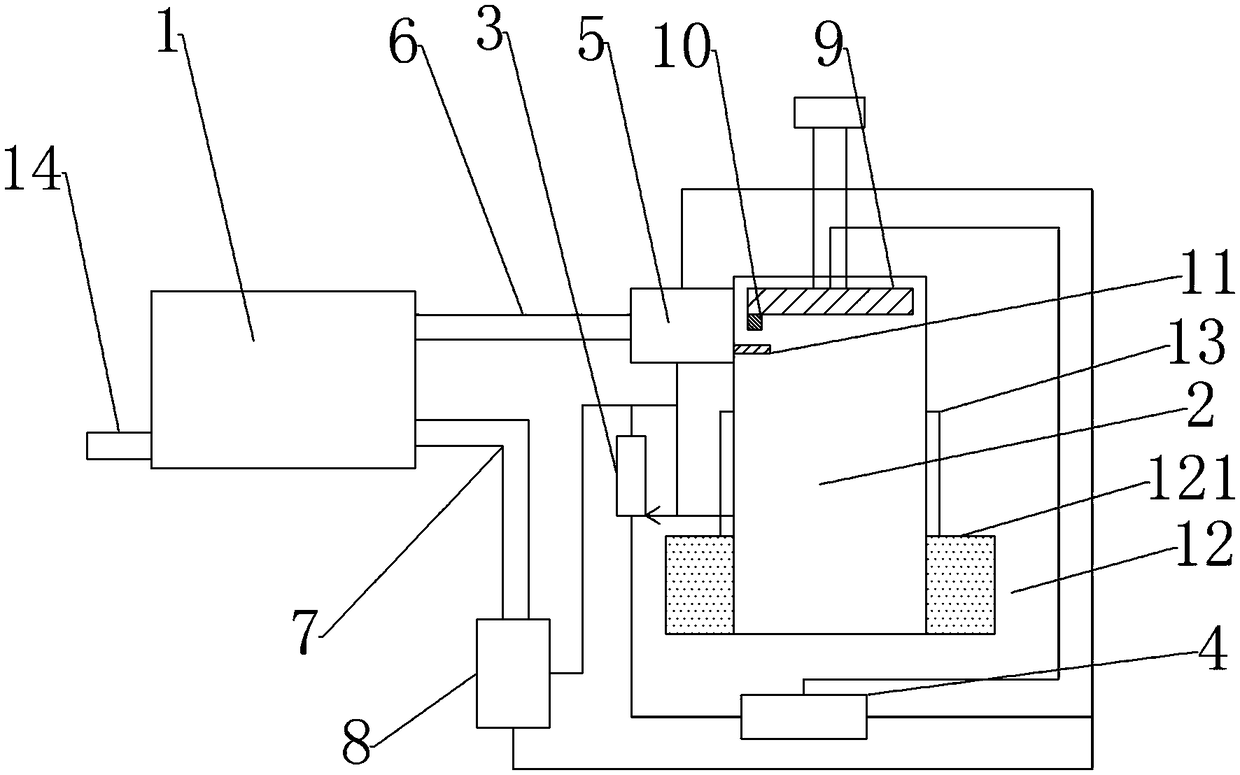

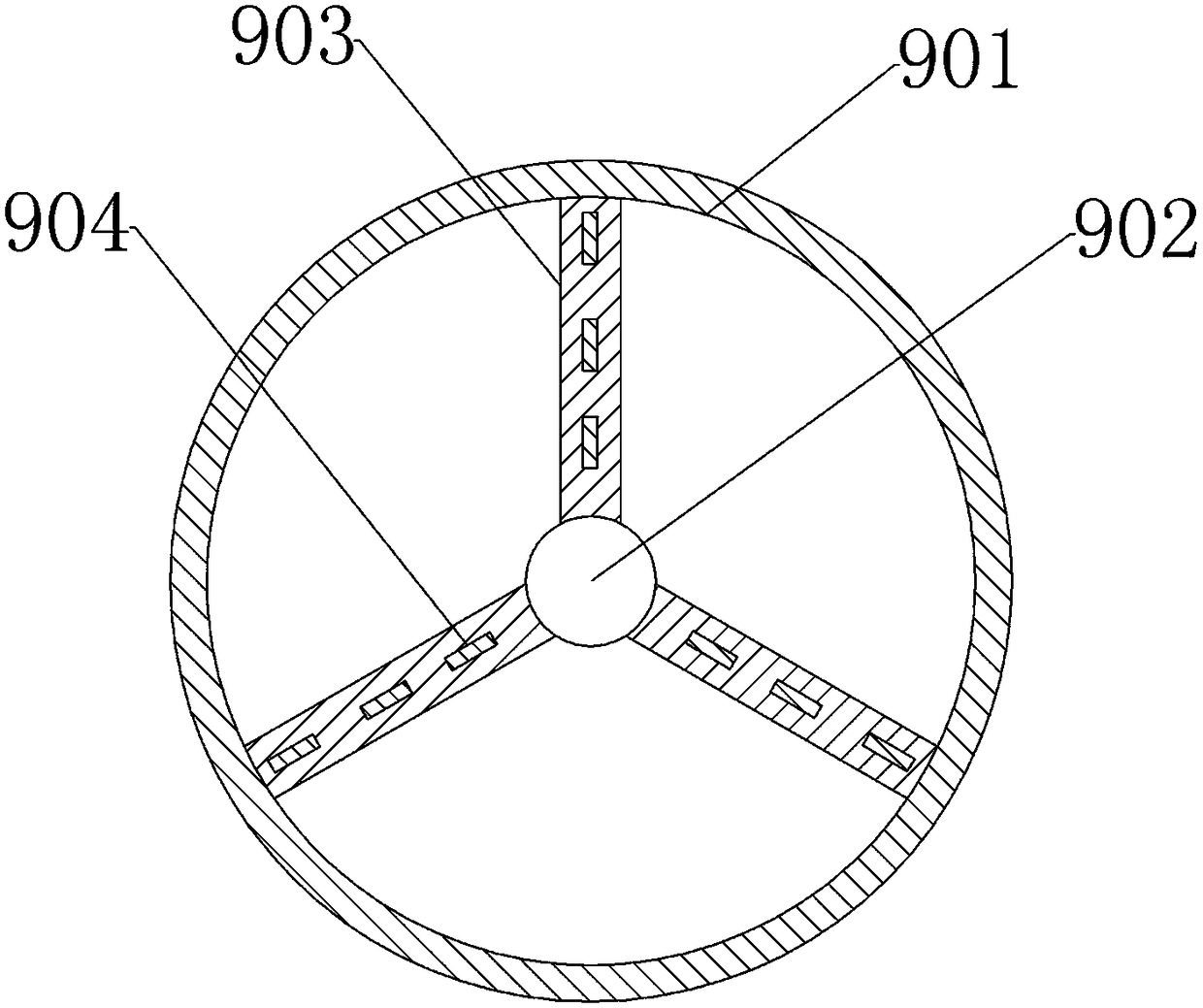

[0023] The reference signs in the accompanying drawings of the description include: grinding device 1, waste material collection tank 2, sliding rheostat 3, power supply 4, waste material lifter 5, feed pipeline 6, water inlet pipeline 7, water pump 8, crushing device 9, circle Shaped frame 901, rotating shaft 902, blade 903, cutter 904, self-resetting switch 10, operation panel 11, liquid storage tank 12, top plate 121, guide sleeve 13, discharge channel 14.

[0024] Example figure 1 and figure 2 As shown, it includes a grinding device 1 and a waste collection tank 2, and the grinding device is provided with a discharge channel 14, a feeding pipeline 6 and a water inlet pipeline 7 communicating therewith. An opening is provided on the top of the waste collection tank 2, and a waste lifter 5 is also provided. The waste lifter 5 is fixedly connected with the feed pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com