Preparation device of supersaturated nanobubble hydrogen solution and preparation method of supersaturated nanobubble hydrogen solution

A technology for preparing device and hydrogen, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve problems such as toxicity, poor metal taste, slow reaction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

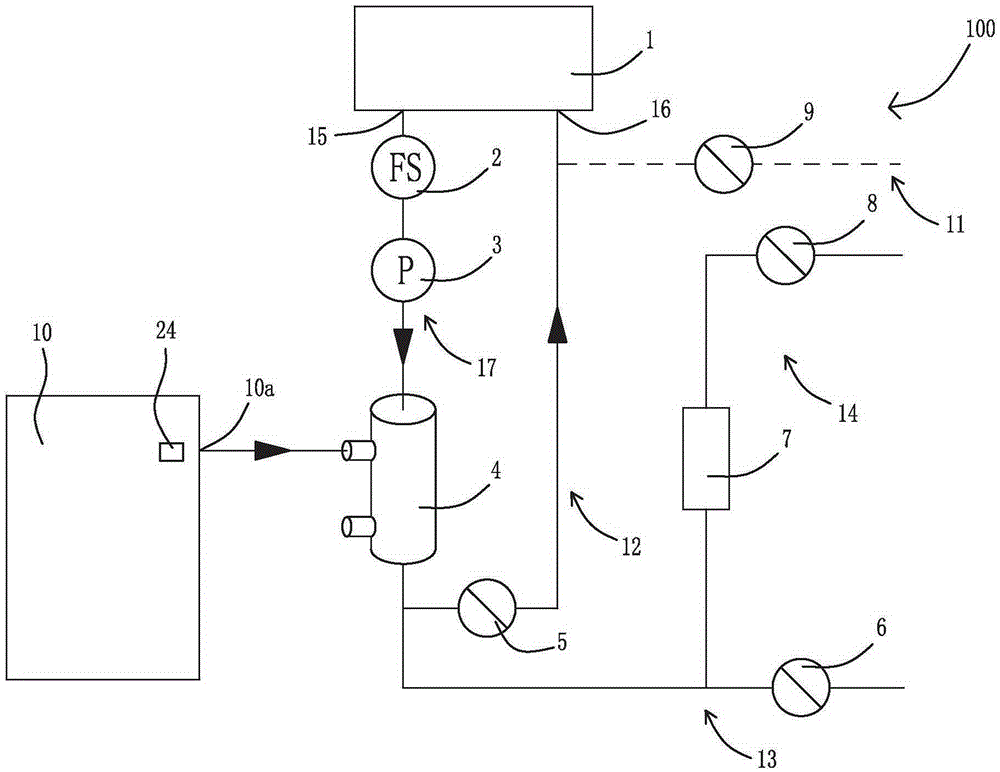

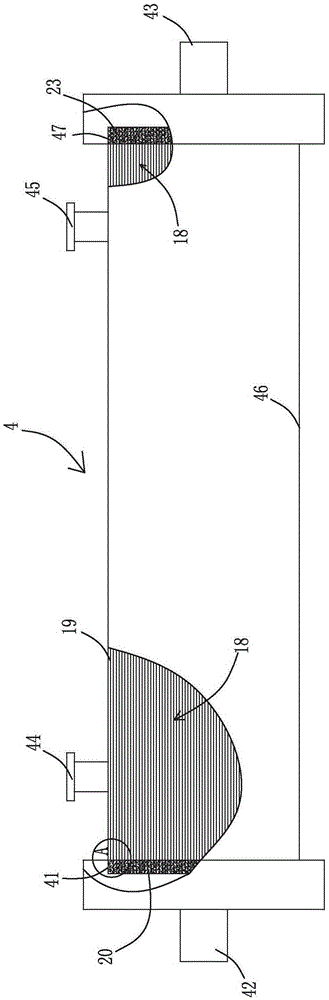

[0108] The key to the preparation device of the supersaturated hydrogen solution of the present invention is to provide a hollow fiber membrane group comprising a plurality of hollow fiber membrane tubes, and then make the liquid flow inside the hollow fiber membrane tubes, and at the same time make the hydrogen pass through the hollow fiber membrane tubes The membrane pores enter the hollow fiber membrane tube and mix with the liquid, thereby producing a supersaturated hydrogen solution. Under the above principle and method, various structural forms of the preparation device can be used to achieve the purpose of the present invention.

[0109] As an illustration, examples of preparing a supersaturated hydrogen solution under different conditions are listed below.

example 1

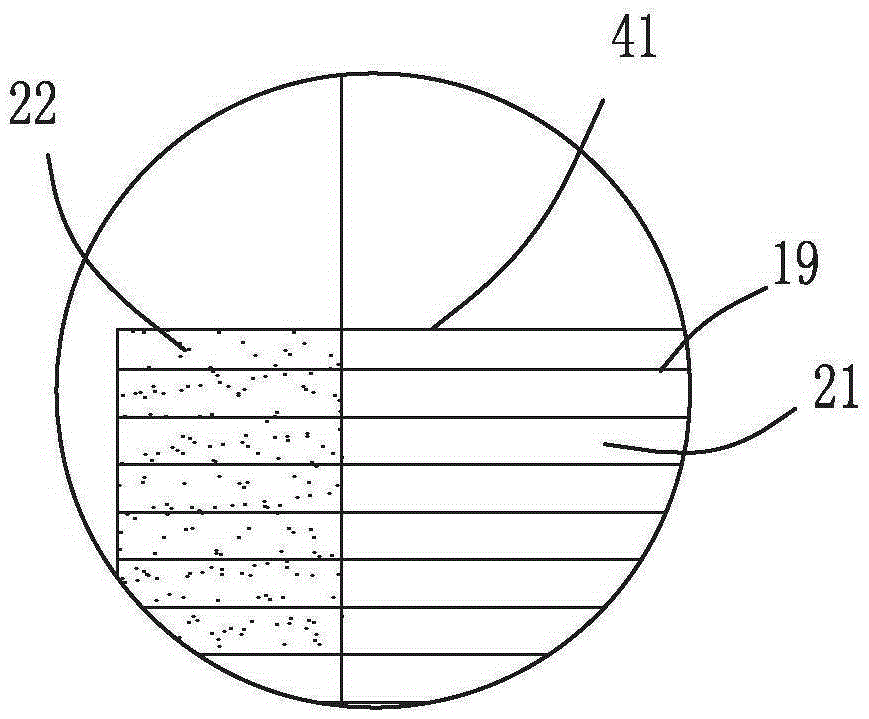

[0111] 15,000 polyethersulfone hollow fiber membrane tubes with an inner diameter of 200 μm, a membrane wall thickness of 35 μm, a membrane pore diameter of 5-7 nm, and a porosity of 40% are packaged in a polycarbonate shell with an outer diameter of 32 mm and a length of 264 mm to form a single group Hollow fiber membrane group gas-liquid mixer, wherein the formed hollow fiber membrane group has a maximum diameter of about 37mm and a total length of about 305mm. The air inlet is connected to a hydrogen generator, the air outlet is connected to a safety valve, the liquid inlet is connected to drinking bottled water through a pipeline, and the water outlet of the pump is connected to a pipeline to discharge water directly. The pressure at the inlet end is maintained at 0.18MPa, the water pressure is normal pressure (about 0.1MPa), the flow rate of the outlet water is stable at 760ml / min, the hydrogen content of the inlet water is 0, and the hydrogen content of the outlet water i...

example 2

[0113] The equipment is the same as Example 1, the pressure at the inlet end is maintained at 0.138MPa, the water pressure is at normal pressure (about 0.1MPa), and the flow rate of the outlet water is greater than 900ml / min. The hydrogen content in the influent water is 0, and the hydrogen content in the effluent water is 3.6ppm, which is 2.25 times the hydrogen saturation at 20°C and 1 standard atmospheric pressure.

[0114] Conclusion: Compared with higher inlet pressure and lower flow rate, the concentration of saturated solution prepared by lower inlet pressure and higher flow rate is significantly lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com