Hand-beating imitated pork meatball dedicated meat-hammering machine

A technology of pork balls and meat hammer machine is applied in the direction of softening, application, and tenderization of meat by beating, which can solve the problems of reducing the quality of meatballs, and achieve the effects of improving elasticity and gel transparency, improving taste, and reducing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

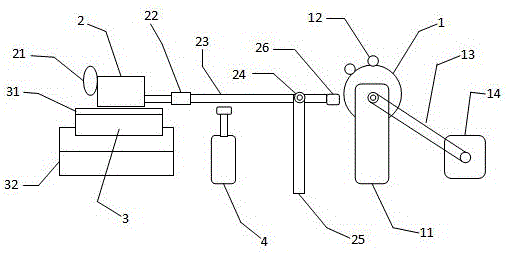

[0025] Such as figure 1 with 2 As shown, a special meat hammering machine imitating hand-made pork balls includes a bone chopping knife 2 and a chopping board 3. The bone chopping knife 2 is a bone chopping knife with an unopened blade, and a counterweight is welded to the front end of the bone chopping knife 2. 21. The back of the bone cutting knife 2 faces downward, the cutting board 3 is arranged under the bone cutting knife 2, the end of the handle of the bone cutting knife 2 is sleeved with a connecting rod 23 through a rubber sleeve 22, and the connecting rod The rear part of 23 is vertically provided with a column 25 through the rotating shaft 24, the end of the connecting rod 23 is provided with a scraper 26, and the rear end of the connecting rod 23 is provided with a drum 1 corresponding to the scraper 26, and the drum 1 is connected by a bearing There is a base 11, the outer surface of the rotating cylinder 1 is provided with a bump 12 corresponding to the scraper ...

Embodiment 2

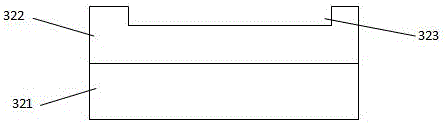

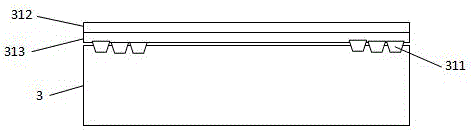

[0027] Such as image 3 As shown, the pigskin 31 adopts pigskin, the dermis 312 of the pigskin is arranged upwards, the epidermis 313 of the pigskin is close to the cutting board 3, and the two sides of the top surface of the cutting board 3 are provided with several Suction cup 311, described suction cup 311 sucks the epidermis 313 of pigskin. Its function is to fix the pigskin through the suction cup 311, prevent the greasy pigskin from deviating, and ensure the integrity of the pigskin edge. Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0029] Such as Figure 4 As shown, the pigskin 31 adopts air-dried pigskin 314, and the two sides of the air-dried pigskin 314 are connected to the cutting board 3 through a fixing mechanism. The fixing mechanism includes: fixed ears 315 arranged on both sides of the cutting board 3, with ratchet The pressing plate 318 of 319 and the screw 316 connecting the fixing ear 315 and the pressing plate 318, the top of the screw 316 is provided with a nut 317, the fixing ear 315 is fixed on both sides of the cutting board 3 by nails, the pressing plate 318 cooperates with the fixing ear 315 A threaded hole for passing through the screw 316 is provided, and the side of the pressing plate 318 with the ratchet 319 is pressed downward toward the edge of the air-dried pigskin 314 . Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com