Tracked microstrainer

A microfilter and crawler-type technology, applied in application, fish farming, animal husbandry, etc., can solve the problems of unsatisfactory cleaning effect, high purchase cost, large space occupation, etc. and operating costs, the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

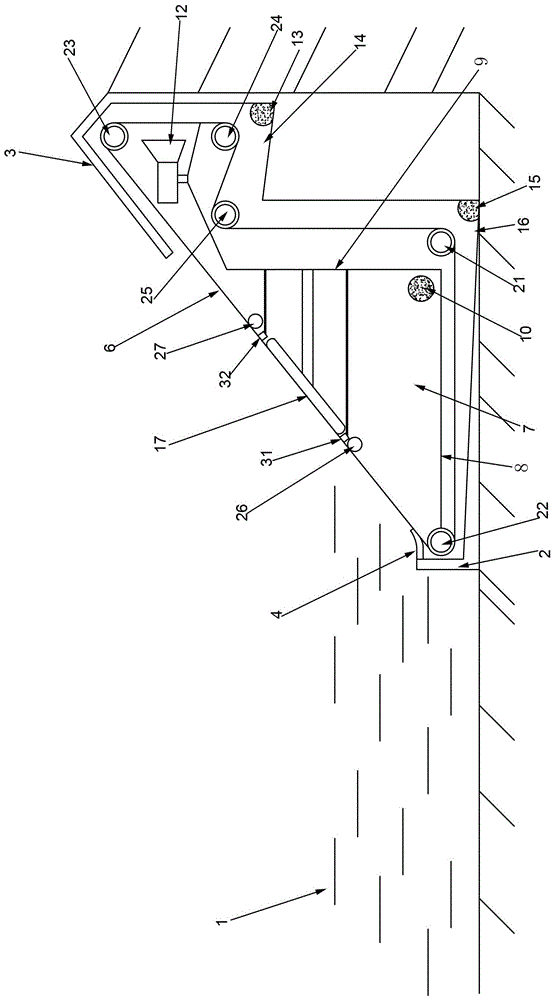

[0027] Such as Figure 1 to Figure 2 As described above, a crawler-type microfiltration machine includes a frame 2 arranged in a water tank 1 , and a cover 3 is provided on the upper end of the frame 2 .

[0028] The bottom is provided with a first support roller 21 and a second support roller 22, the top is provided with a third support roller 23, the middle part is provided with a fourth support roller 24 and a fifth support roller 25, and the inside of the filter cloth 6 bypasses the first support roller 21. The second support roller 22 , the third support roller 23 , the fourth support roller 24 , and the fifth support roller 25 are close to the outside of the filter cloth 6 , so that the filter cloth 6 is in a tensioned state, showing an inverted ladder shape. The filter cloth 6 is made of polyester material, which can effectively remove suspended particles with a diameter of more than 30 μm in the water body through tests. Machine cover can prevent dust from dirtying th...

Embodiment 2

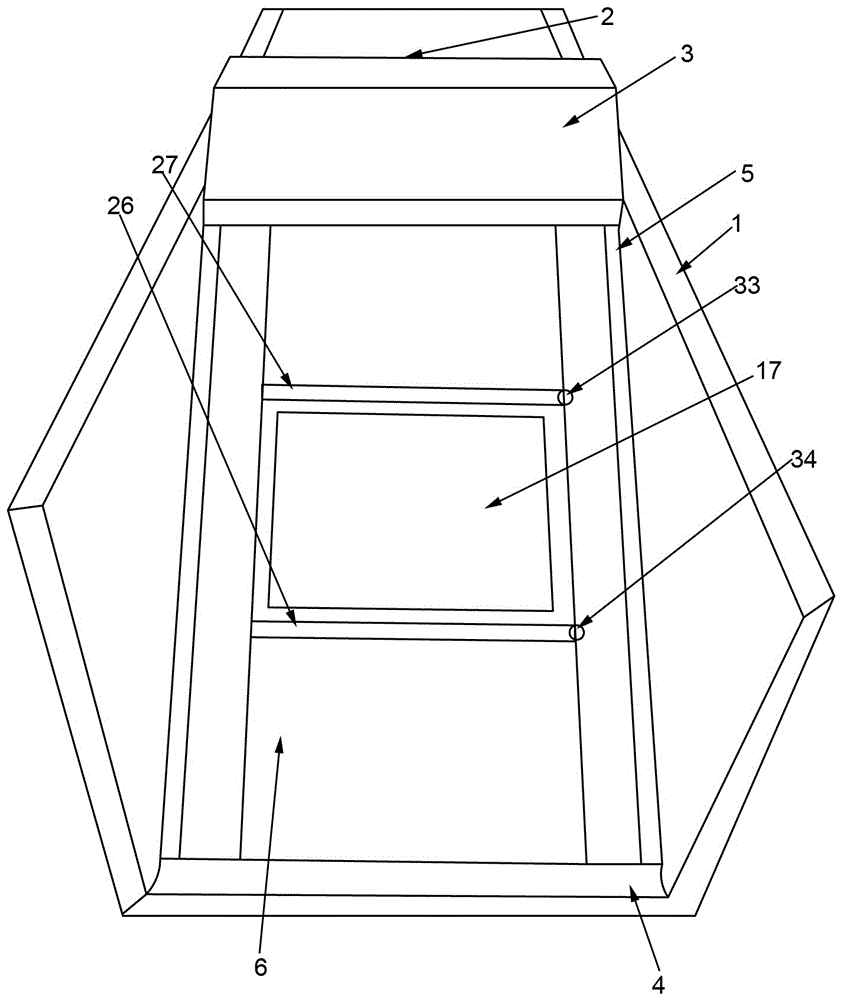

[0036] Different from Embodiment 1, this device does not have a water level sensor, but a sixth support roller 26 and a seventh support roller 27 are arranged between the second support roller 22 and the third support roller 23, and the sixth support roller 26 Located below the ultrasonic vibrating plate 17 , the seventh support roller 27 is located above the ultrasonic vibrating plate 17 . A first pressure sensor 33 and a second pressure sensor 34 are arranged below the sixth support roller 26 and the seventh support roller 27 respectively; the first pressure sensor 33 and the second pressure sensor 34 are respectively electrically connected to the controller. For the device where the sixth and seventh support rollers are arranged between the second and third support rollers, pressure sensors can be further installed under the sixth and seventh support rollers to detect the water level and make the detection more accurate.

Embodiment 3

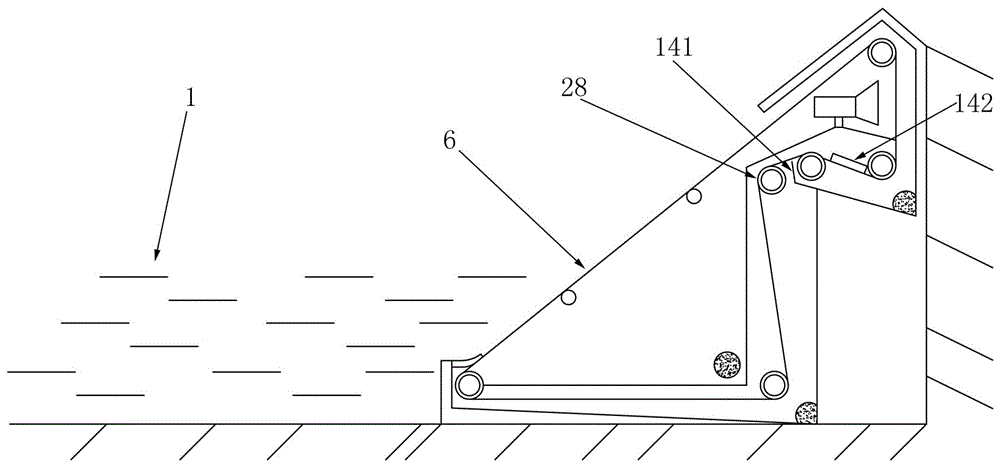

[0038] Such as figure 1 and image 3 As shown, a crawler-type microfiltration machine includes a frame 2 arranged in a water tank 1, a machine cover 3 is provided at the upper end of the frame 2, a first support roller 21 and a second support roller 22 are provided at the bottom, and a second support roller 22 is provided at the top. Three supporting rollers 23, the middle part is provided with the fourth supporting roller 24, the fifth supporting roller 25, the inner side of the filter cloth 6 bypasses the first supporting roller 21, the second supporting roller 22, the third supporting roller 23, the fourth supporting roller 24, The fifth support roller 25 is close to the outer side of the filter cloth 6, so that the filter cloth 6 is in a tight state, showing an inverted ladder shape; the third support roller 23 is connected with a motor, and the motor drives the third support roller 23 to rotate, so as to realize the circulation of the filter cloth 6 Transmission; the fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com