Multifunctional combined no-tillage film laying and dibbling machine

A combined operating machine and multi-functional technology, applied in the field of agricultural machinery, can solve problems affecting the normal operation of tractors, walking on the road, and inconvenient turning around in the field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

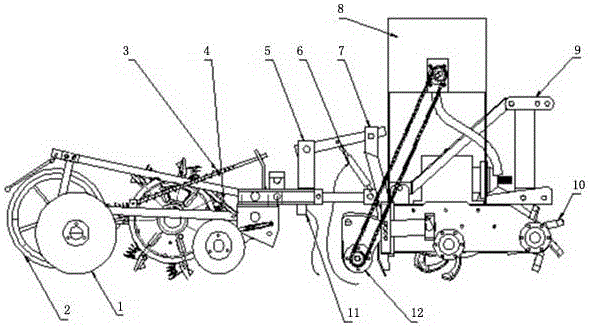

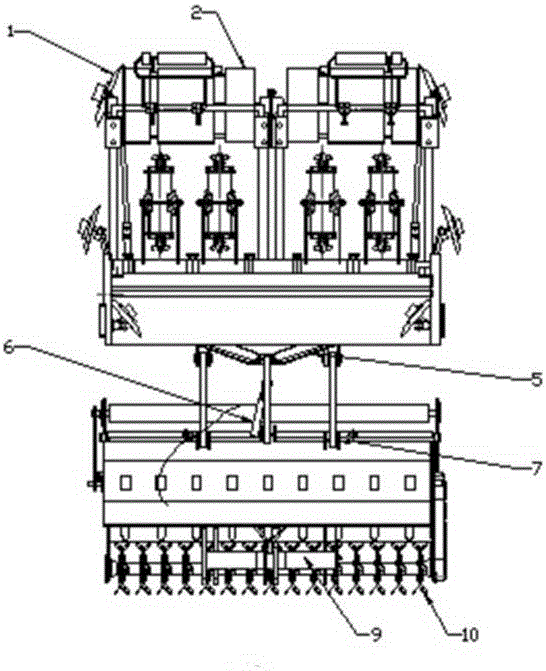

[0024] A multi-functional no-tillage, film-laying, film-on-demand combined operation machine, including soil covering, on-demand seeding, suppression, fertilization, stubble removal and spraying mechanisms, characterized in that the soil covering, on-demand, and chemical spraying mechanisms are arranged at the rear of the frame 5, suppressing, The fertilization and stubble removal mechanism are located at the front part of the frame 5; the fertilization box 8 of the fertilization mechanism is respectively provided with a front hitch 9 and a rear hitch 7, and the lower part of the fertilization box 8 is provided with a pressing roller 12 and a stubble cutter 10, and the rear hanger The connecting frame 7 is connected with the frame 5 through the oil cylinder 6 .

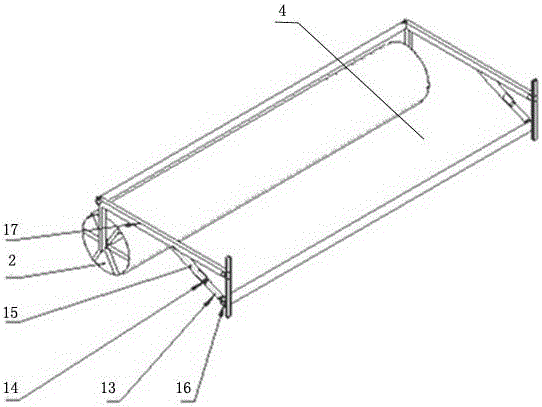

[0025] The soil-covering cylinder 2 of the soil-covering mechanism is connected with the frame 5 through an adjustable limit device 4, and the adjustable limit device 4 includes an adjustment pipe 13, an adjustment nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com