Method and equipment for leaking radiation testing of radiation source components

A technology of testing equipment and a testing method, which is applied in the field of radiation leakage testing of radiation source components, can solve problems such as high equipment procurement costs and high maintenance costs, and achieve the effects of taking into account both testing accuracy and testing efficiency, reducing costs, and simplifying testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

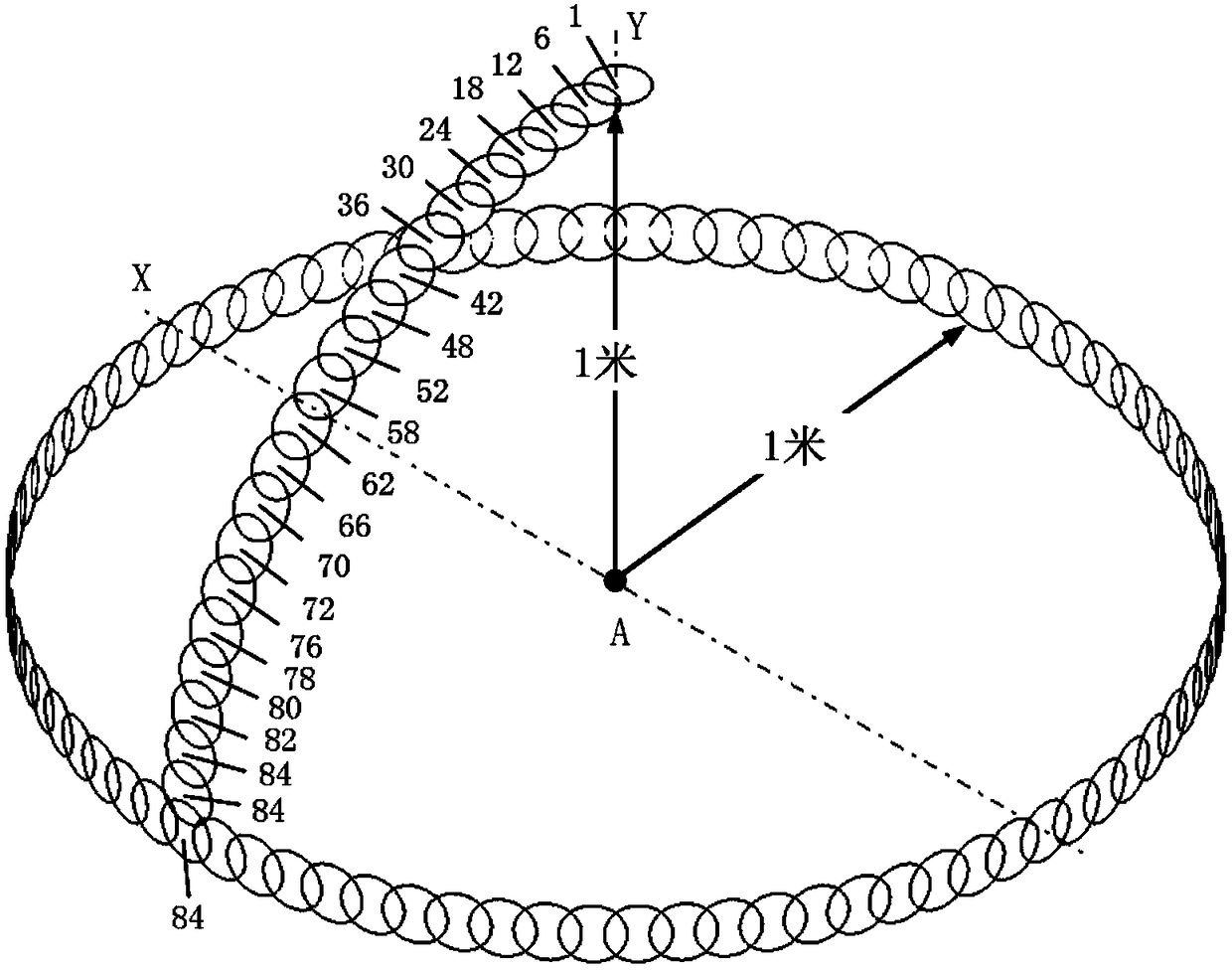

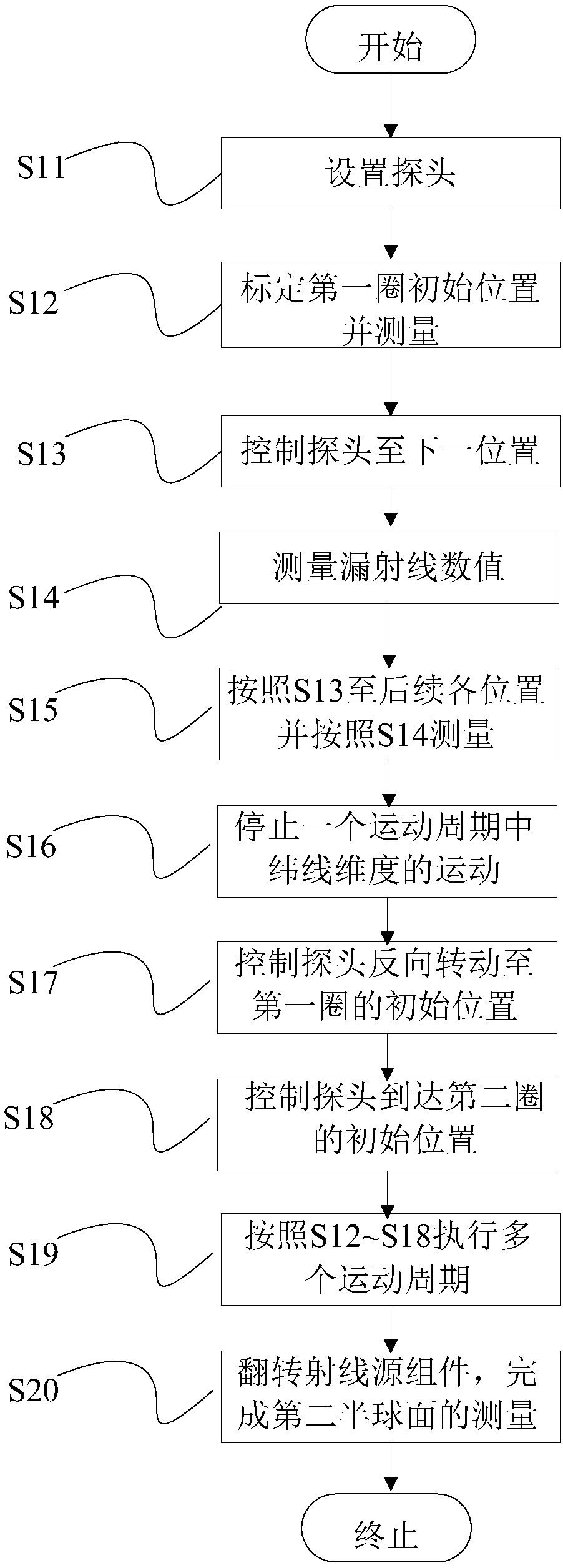

Embodiment 1

[0099] like Figure 4 As shown, in a specific embodiment, the first swing arm 2 can be L-shaped, its horizontal part is used to be hinged with the mounting base 4, and the vertical part is hinged with the second swing arm 3, and the first swing arm 2 The vertical part can be arranged perpendicular to the rotary shaft of the second rotary arm 3. At this time, the rotary shaft of the first rotary arm 2 is in a direction parallel to the vertical part.

[0100] In detail, this embodiment is also provided with a column 9 and a supporting plate 10, the central axis of the column 9 coincides with the axis of rotation of the first rotary arm 2, and the lower end of the column 9 is hinged with the transverse part of the first rotary arm 2. At this time, the column 9 is used as the rotating shaft of the first rotating arm 2; the upper end of the column 9 is provided with a supporting plate 10, and the mounting seat 4 is detachably arranged on the supporting plate 10. Through this struc...

Embodiment 2

[0120] like Figure 5 As shown, in another specific embodiment, the first slewing arm 2 can be in the form of a broken line, including a first arm 21 and a second arm 22 connected to each other, wherein the first arm 21 extends from top to bottom, and the second arm 21 extends from top to bottom. The arm 22 is bent from the lower end of the first arm 21 towards the focal point A of the radiation source in the radiation source assembly, the upper end of the first arm 21 is hinged to the second rotating arm 3, and the second arm 22 is connected with a rotating shaft 23 extending up and down as the first The rotating shaft of a rotating arm 2, that is to say, the rotating shaft 23 can rotate relative to the mounting seat 4, so as to realize the rotation of the first rotating arm 2 relative to the mounting seat 4, and at the same time, the mounting seat 4 is directly above the rotating shaft 23, so as to It is ensured that the rotating shaft 23 can pass through the focal point A o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com