Method for pretreating air or fuel gas through high-voltage electrostatic field

A high-voltage electrostatic field and pretreatment technology, applied in the field of high-voltage electrostatic field pretreatment of air and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

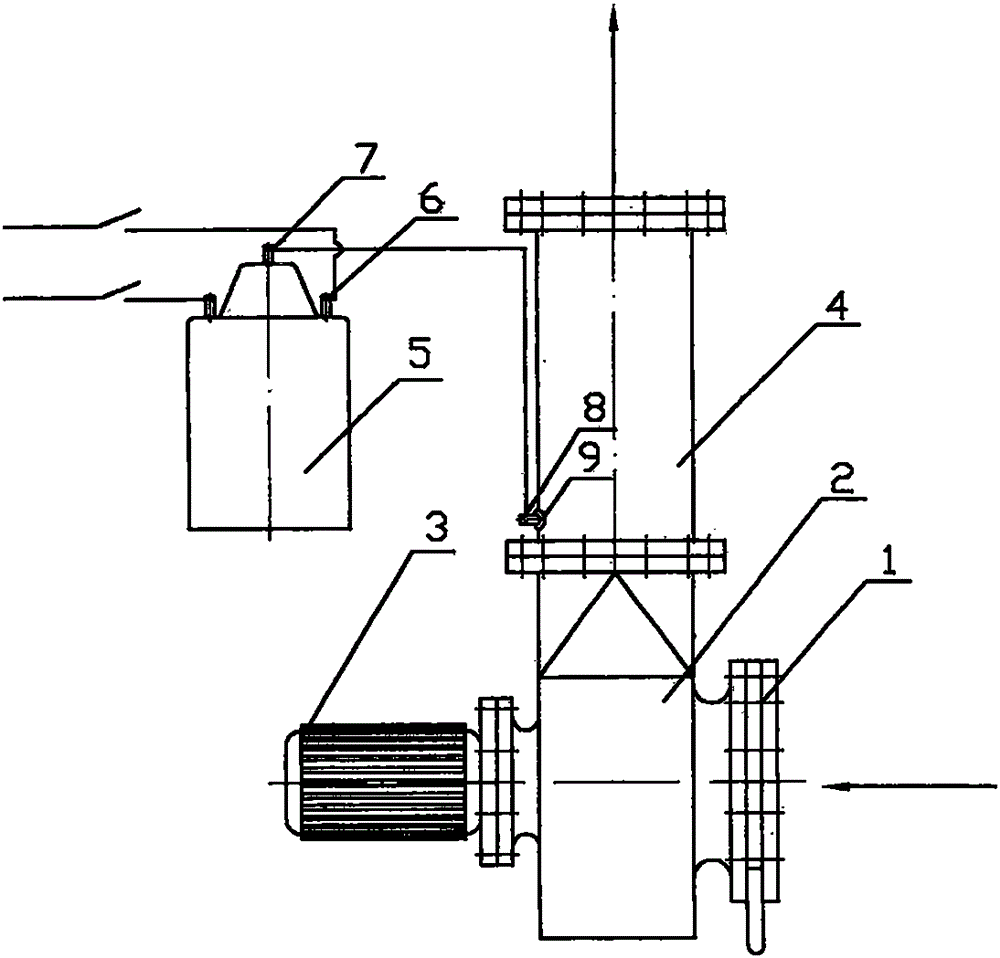

[0010] exist figure 1 Among them, the blower 2 is equipped with a motor 3, the air inlet of the blower is equipped with a damper 1, the outlet of the blower is connected with one end of the metal ionization tube 4, the other end of the metal ionization tube 4 is connected with the boiler combustion chamber, and the primary winding terminal 6 Connected to the network power supply, the secondary winding terminal 7 is connected to the high-voltage spiral electrode terminal 8 passing through the insulating rubber gasket 9 .

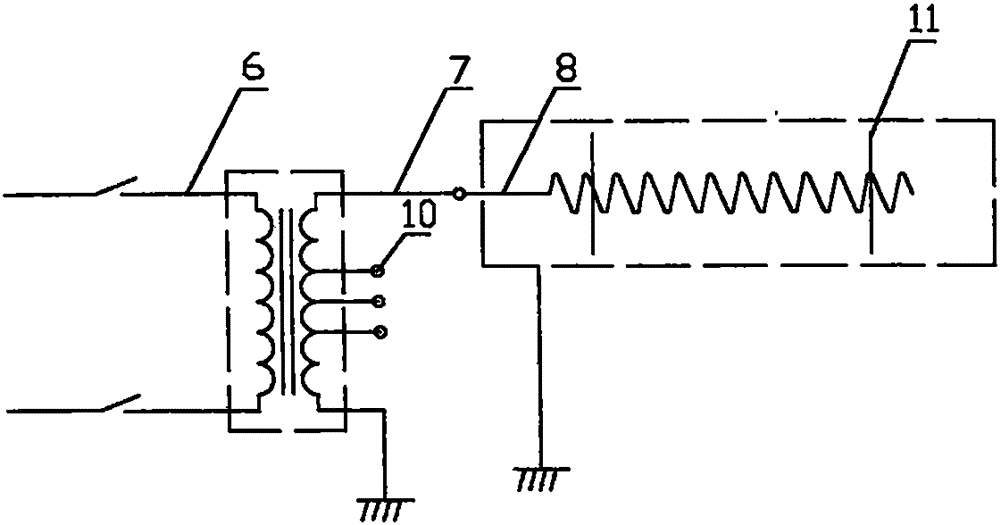

[0011] exist figure 2 In the shown embodiment, the metal ionization tube 4 is grounded to form a circuit of the high-voltage electrode, and the high-voltage spiral electrode is fixed on the insulating tripod support frame 11 , and the output voltage is adjusted through the tap 10 of the secondary winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com