Jacking type hydraulic substation system

A hydraulic substation and jacking technology, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, and container discharge methods, etc., can solve the problems of long strokes of hydraulic cylinders, large lifting angles, etc. Small area, compact structure, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

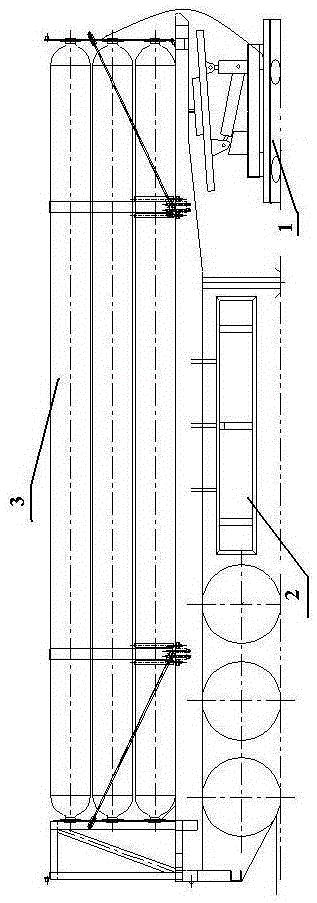

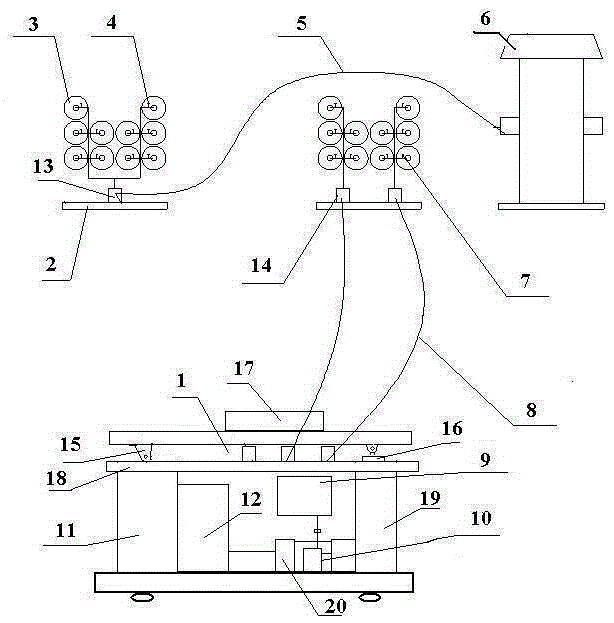

[0016] see figure 1 and figure 2 Shown, the present invention comprises trailer 2 that ten cylinders are housed, ground hydraulic jacking device 1, substation hydraulic oil tank 9, hydraulic pump 10, gas filling machine 6, is fixed with ten independent cylinders on the traveling mechanism of trailer 2 The gas cylinders 3, the front end of each gas cylinder 3 is an air inlet and outlet circuit, and its rear end is an oil inlet and outlet circuit, all of which are pneumatic valve control switches. All the inlet and outlet gas lines converge to an air tube socket 13, and the oil inlet and outlet channels of every five gas cylinders converge to an oil tube socket 14. Both the gas tube socket 13 and the oil tube socket 14 are equipped with quick connectors, which are connected through a high-pressure soft The pipes are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com