High-pressure self-sealing valve

A self-closing, high-pressure technology, applied in valve device, valve details, valve shell structure, etc., can solve the problems of complex internal structure, poor reliability of self-closing function, large valve volume, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

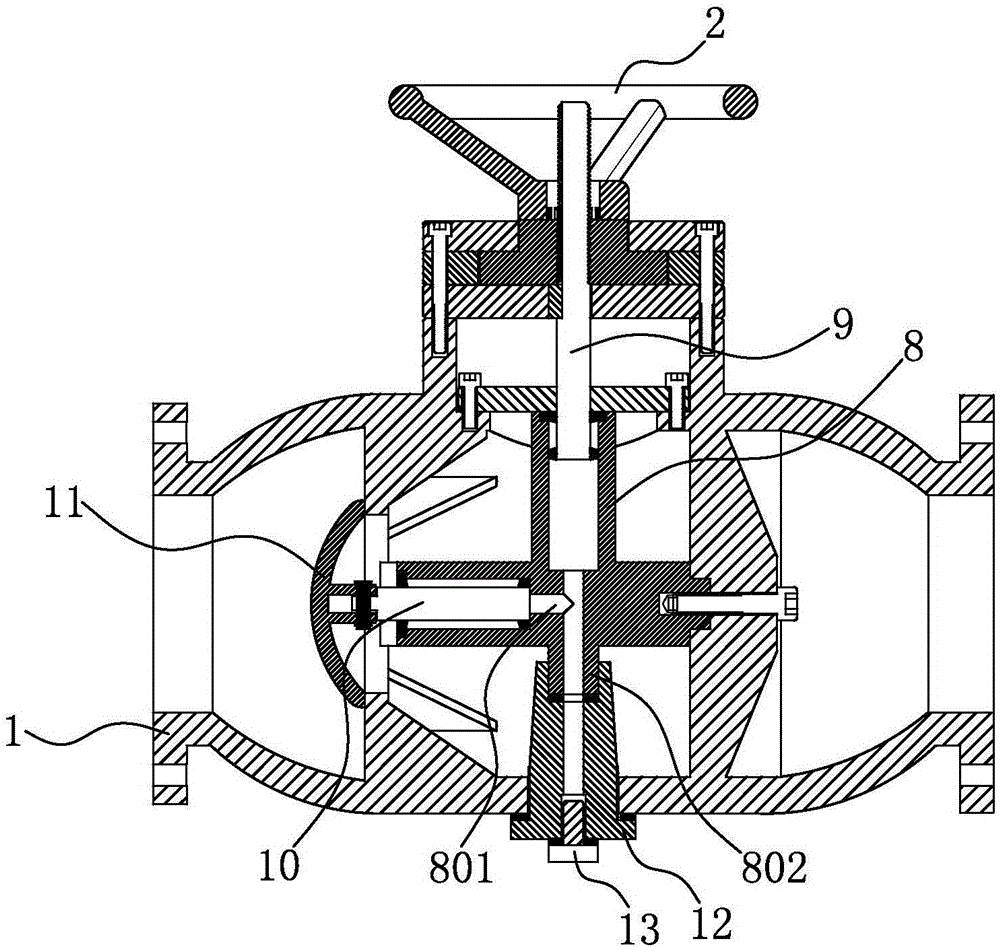

[0014] Now in conjunction with accompanying drawing, the present invention will be further described.

[0015] Such as figure 1 As shown, the high-pressure self-closing valve includes a valve body 1, a valve core assembly, a hand wheel 2, a hand wheel limiting plate 3, a hand wheel positioning plate 5, a guiding positioning plate 6, and a sealing plate 7. The valve body is provided with an inlet 101, an outlet 102, and an operating port 103, and the inlet and the outlet are straight-through, and the operating port is vertical relative to the straight-through direction. The valve body is provided with a connected front bracket 104 and a rear bracket 106. The internal wall is strengthened and fixed by triangular ribs, the front bracket is provided with a valve port 105 leading to the inlet and the outlet along the straight direction from the inlet to the outlet, and the rear bracket is provided with a port connecting the inlet and the outlet. A spool assembly is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com