Method and device for adjusting steam turbine gas seal with jet auxiliary center support for damping vibration

A technology for auxiliary centers and steam turbines, applied to mechanical equipment, engine components, machines/engines, etc., to achieve the effects of reducing steam leakage, maintaining stability, and reducing radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

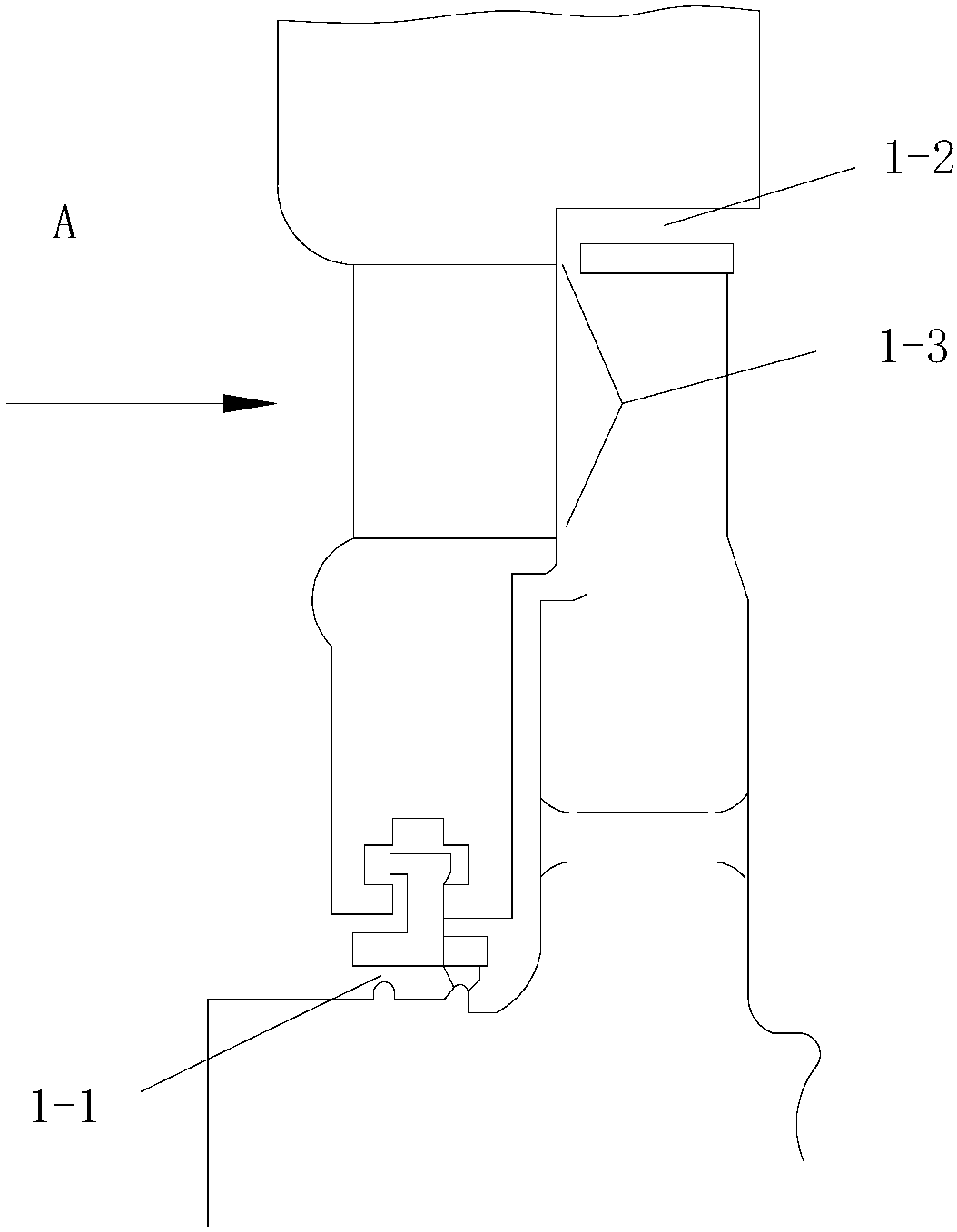

[0045] Specific implementation mode one: the following combination Figure 6 to Figure 12 This embodiment will be specifically described. This implementation mode is realized through the following steps:

[0046] 1. Start the steam turbine; before starting, the gap t between the surface of the inner hole of the air seal assembly at the top of the moving blade of the steam turbine and the outer surface of the turbine blade is between 1.5 and 10 mm;

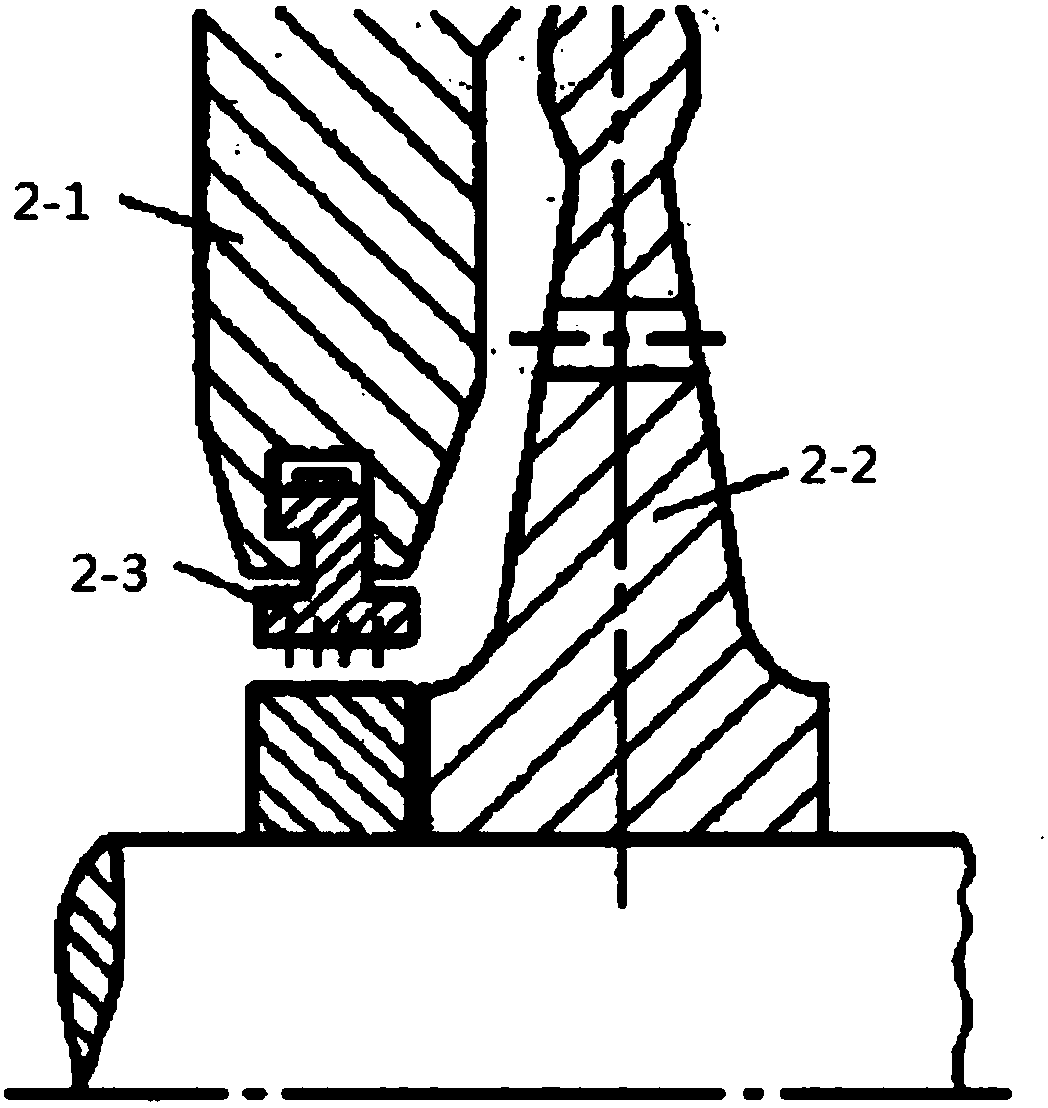

[0047] 2. After the steam turbine reaches the normal speed, adjust the auxiliary support assembly arranged at the inner hole of the partition, so that the auxiliary upper bearing bush and the auxiliary lower bearing bush on the auxiliary support assembly gradually tend to close up and surround the main shaft of the steam turbine, so as to reduce the diameter of the main shaft of the steam turbine. In the initial state, the distance between the inner surface of the auxiliary upper bearing bush 7-1 and the auxiliary lower bearing bu...

specific Embodiment approach 2

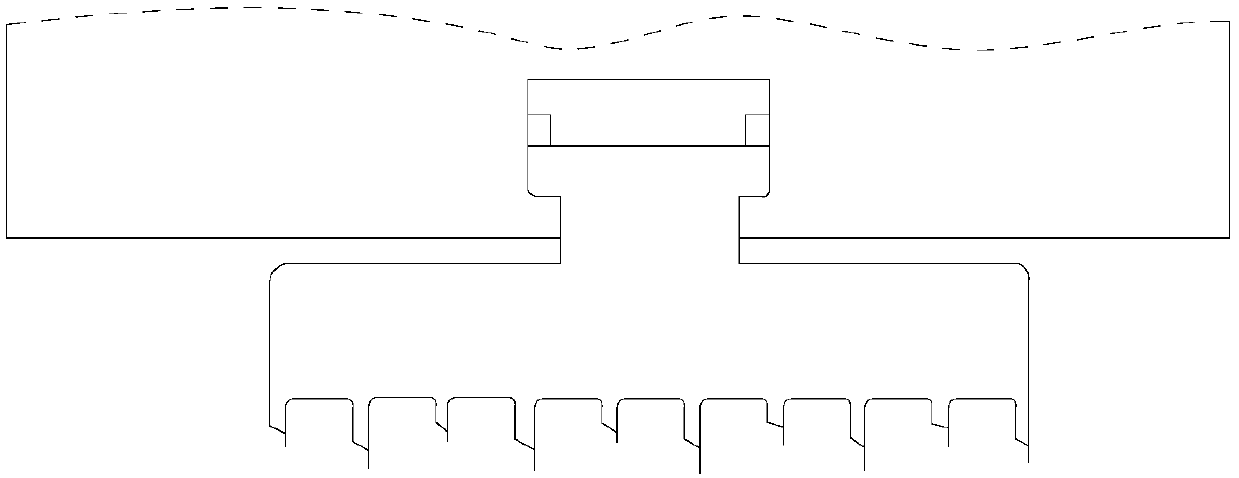

[0057] Specific implementation mode two: the following combination Image 6 , 8 and Figure 9This embodiment will be specifically described. This embodiment is compared with Embodiment 1: this method also includes three groups of distance sensors 6-14 and a group of vibration sensors 8-1, and the group of distance sensors 6-14 is arranged on the air seal body 6-11 for real-time Measure the gap between the gas seal body 6-11 and the outer surface of the steam turbine blade 6-12 and the radial runout of the outer surface of the steam turbine blade 6-12; the other group of distance sensors 6-14 is arranged on the main upper bearing bush 9-1 and the main On the lower bearing bush 9-2, to measure the gap between the main upper bearing bush 9-1 and the main lower bearing bush 9-2 and the steam turbine main shaft 9-3 and the radial runout of the steam turbine main shaft 9-3 in real time; the other set of distance sensors 6 -14 is set on the auxiliary upper bearing shell 7-1 and th...

specific Embodiment approach 3

[0061] Specific implementation mode three: the following combination Image 6 This embodiment will be specifically described. The fifth step also includes the following technical means. During the process of making the surface of the inner hole of the air seal assembly at the top of the moving blade close to the outer surface of the steam turbine blade 6-12, the outer surface of the air seal body 6-11 and the steam turbine blade 6-12 are collected in real time. The surface gap, the radial runout of the outer surface of the steam turbine blade 6-12, and the vibration data collected by the vibration sensor 8-1 are used to ensure that the value of the gap is always greater than the value of the radial runout. Increase the distance between the surface of the inner hole of the air seal assembly at the top of the moving blade and the outer surface of the turbine blade 6-12, and resume operation when the vibration data returns to the value before the abnormal increase. The abnormal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com