One-time pouring forming construction method of partition beam in elevator shaft

A construction method and elevator shaft technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of difficult construction, high cost, and slow construction progress of partition beams in elevator shafts, and achieve simplified construction , reduce stamping, and speed up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

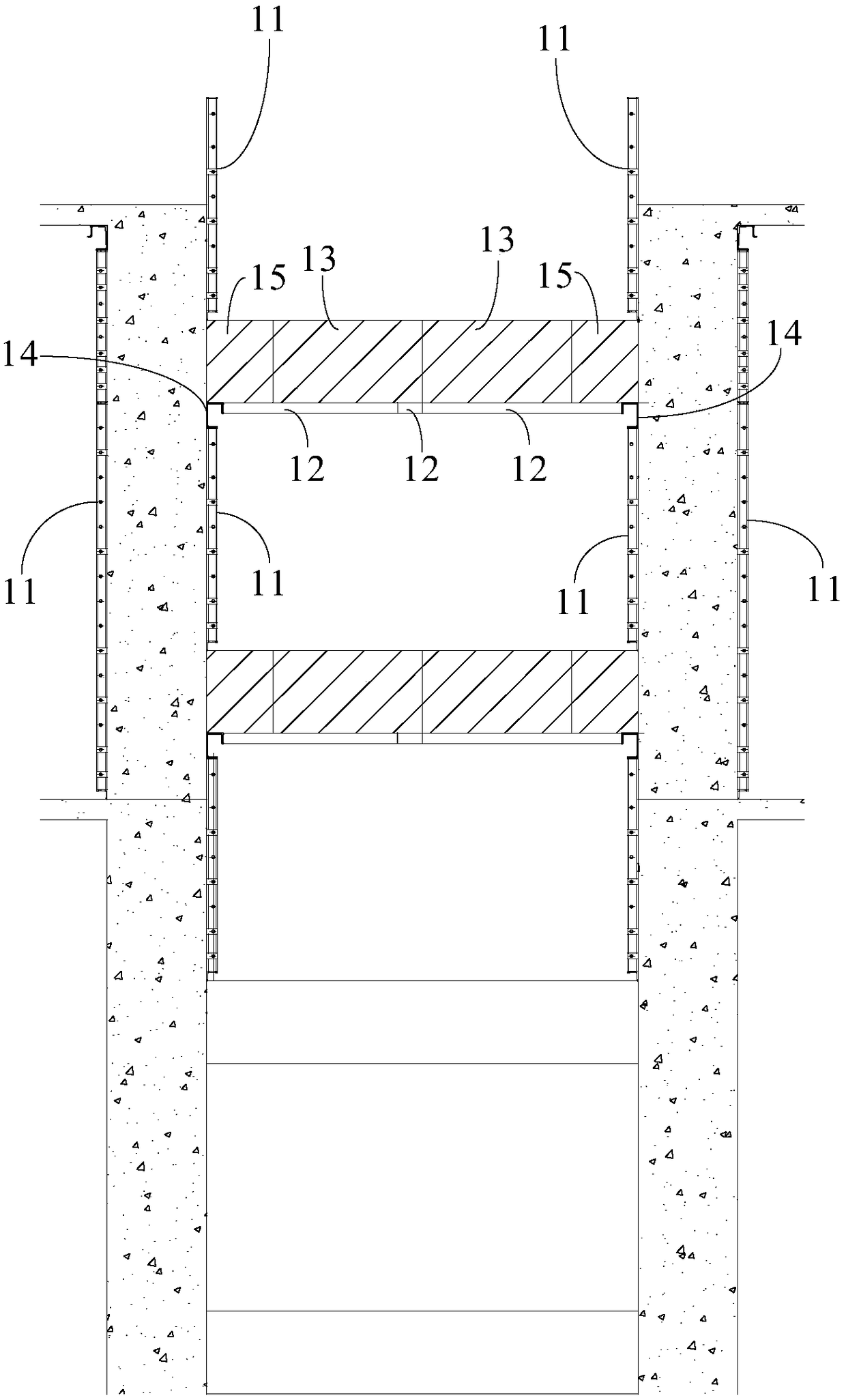

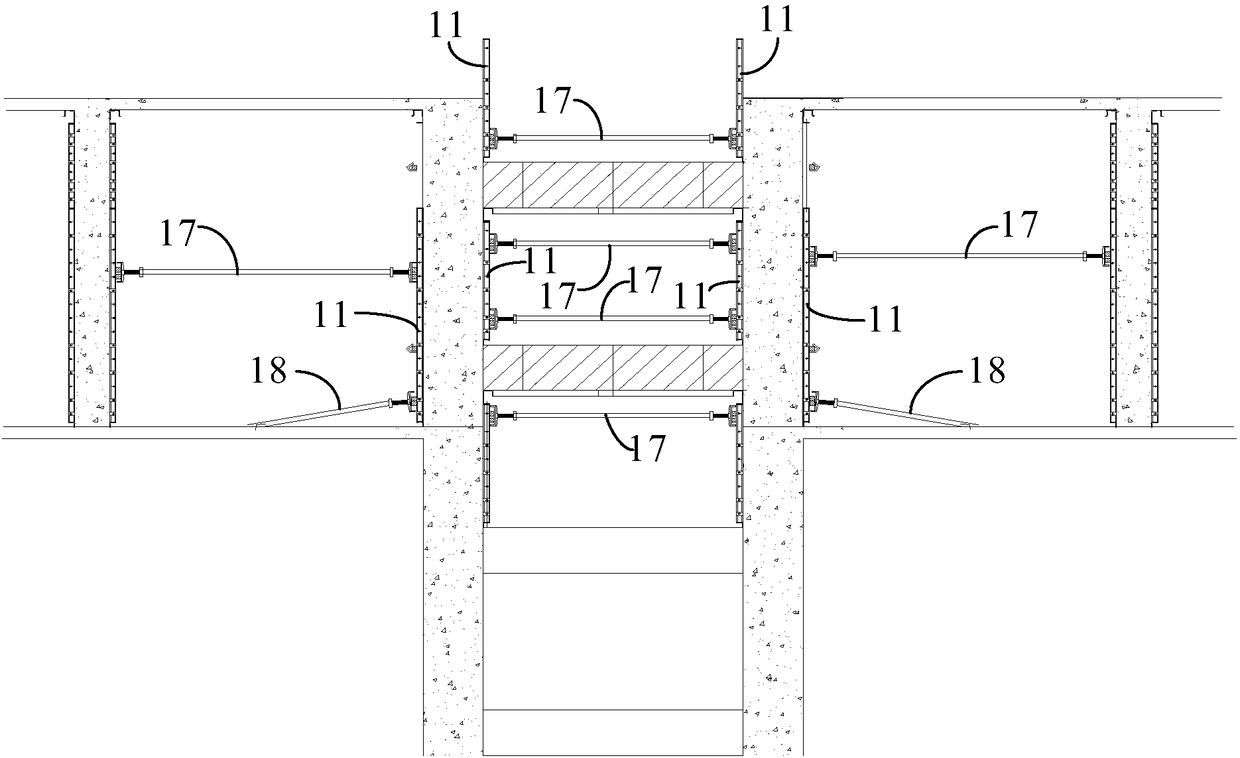

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The construction method of one-time pouring and forming of the inner partition beam of the elevator shaft of the present invention mainly realizes the one-time pouring of the elevator shaft inner partition beam, the shear wall, and the structural beam slab under the condition that the distance between the inner partition beam and the height of the structural floor slab is not an integer multiple. The construction method simplifies the construction of the inner partition beam, speeds up the construction progress and reduces the project cost.

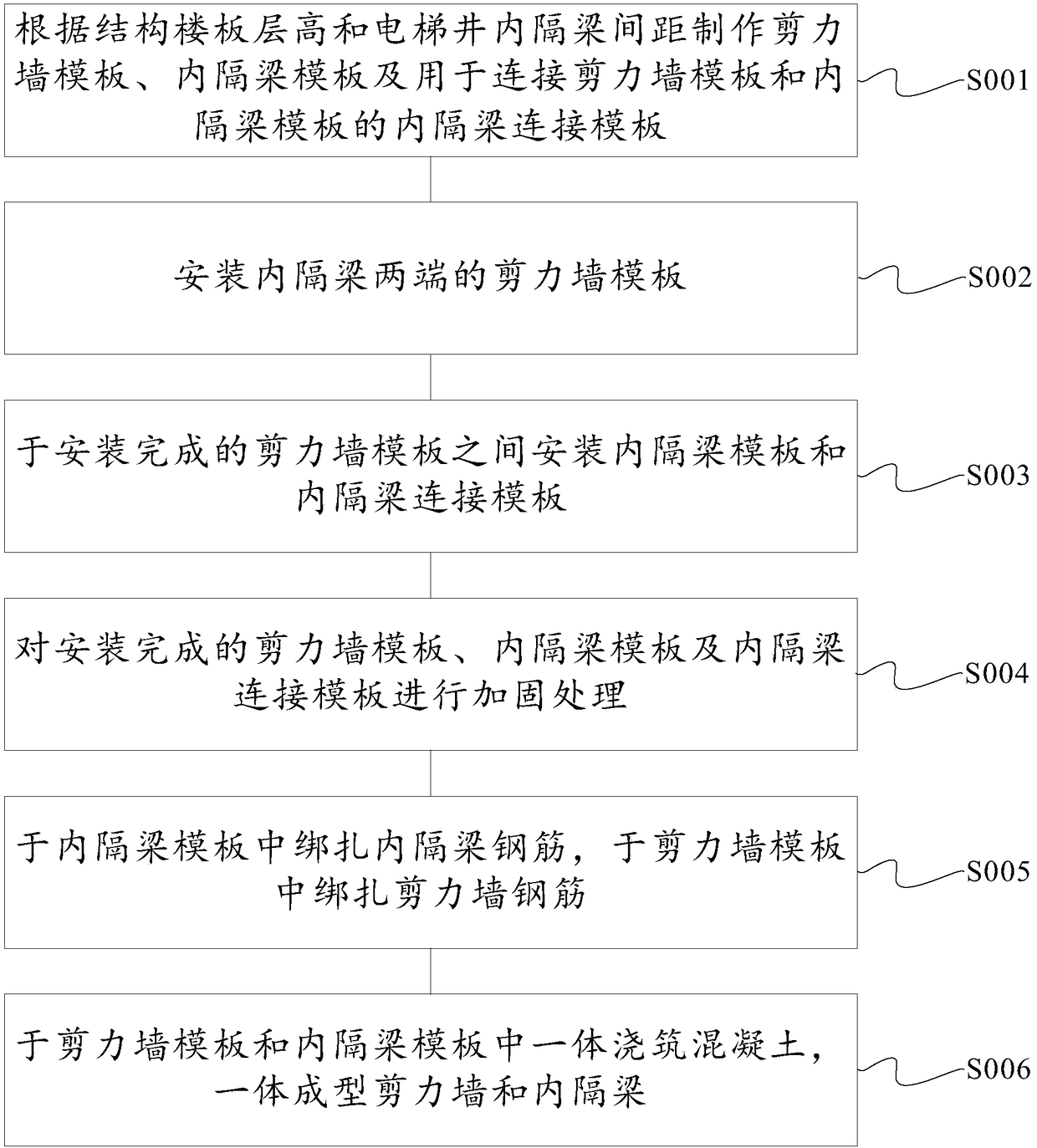

[0046] see first figure 1 Shown, be the process flow diagram of one-time pouring forming construction method of partition beam in the elevator shaft of the present invention, it specifically comprises following construction technology:

[0047] S001: According to the height of the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com