VARI (Vacuum Assistant Resin Infused) integral moulding clear dimension composite material ribbed structure manufacturing method

A technology of integral molding and composite materials, which is applied in the field of VARI integral molding and net-size composite material reinforced structure manufacturing, can solve the problems of high manufacturing cost and poor connection strength, reduce assembly workload, improve rigidity and strength, and process low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

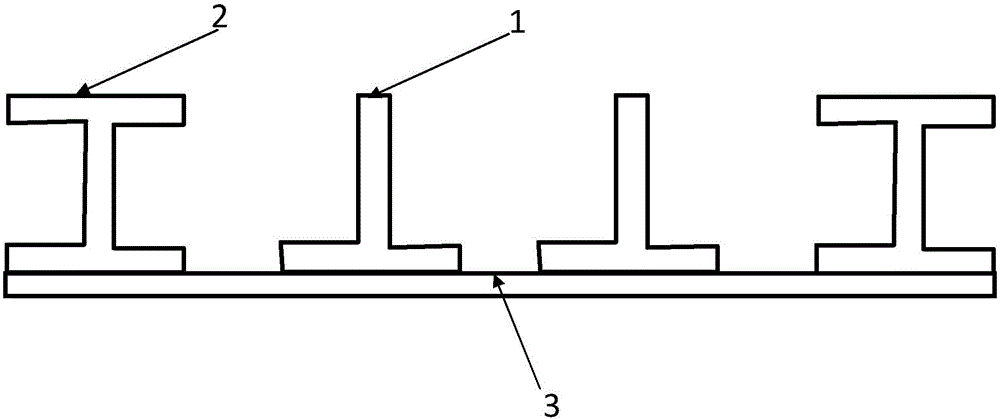

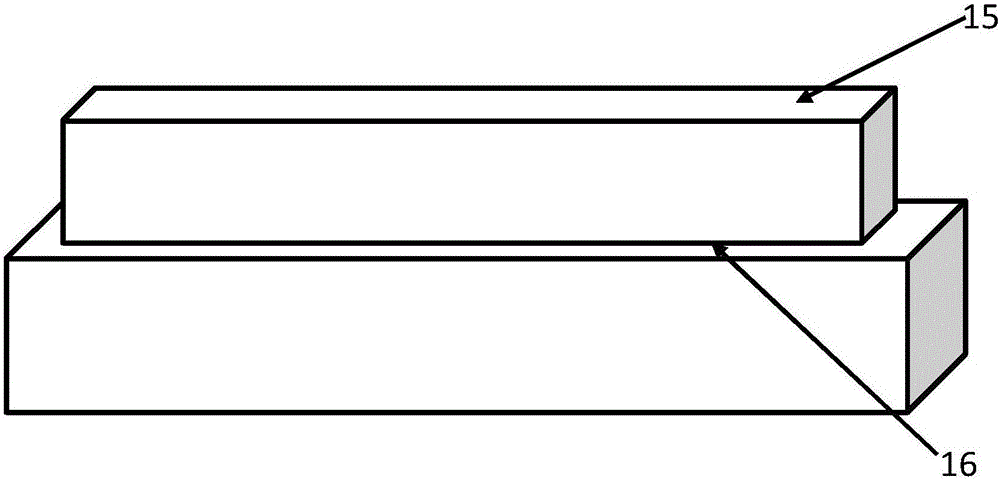

[0025] attached figure 1 It is a schematic cross-sectional view of a composite material reinforced structure. It can be seen from the figure that the net size composite material reinforced structure is composed of a skin 3, an internal reinforcing rib "C" type rib 1 and an I-beam 2. The existing forming process of the composite material reinforced structure is to use the autoclave process to separately form the skin and internal reinforcement, then process the skin and reinforcement to the required size, and then use riveting or screw connection to connect the skin and the internal reinforcement. The tendons are connected together. This connection method is a point connection, and the connection strength is not good. In addition, the process cost of prepreg storage and curing in the autoclave process is very high.

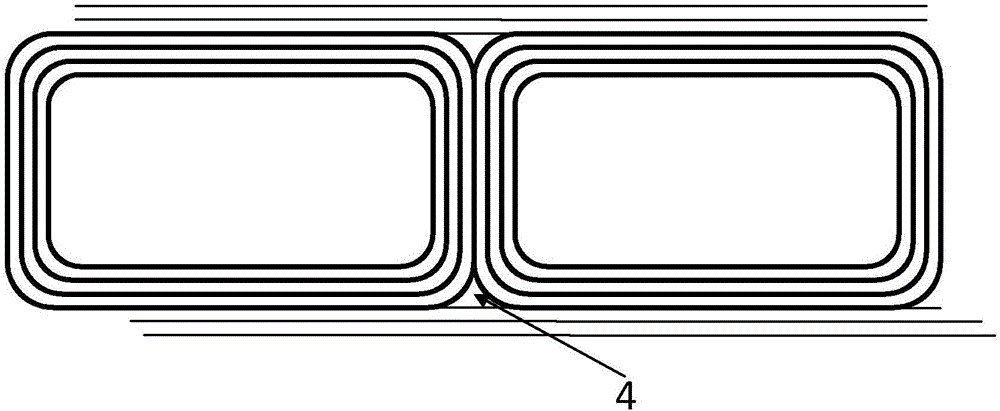

[0026] The manufacturing method of the VARI process of the present invention to integrally form a net-sized composite material reinforced structure comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com