Plastic pipe production line

A production line and plastic tube technology, applied in the direction of tubular objects, metal processing, and other household appliances, can solve the problem of unfavorable product brand establishment product cost control, manual counting does not have a stable accuracy rate, and the number of plastic tubes is too much or too much Less problems, to achieve the effect of improving accessibility, increasing the speed of counting, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

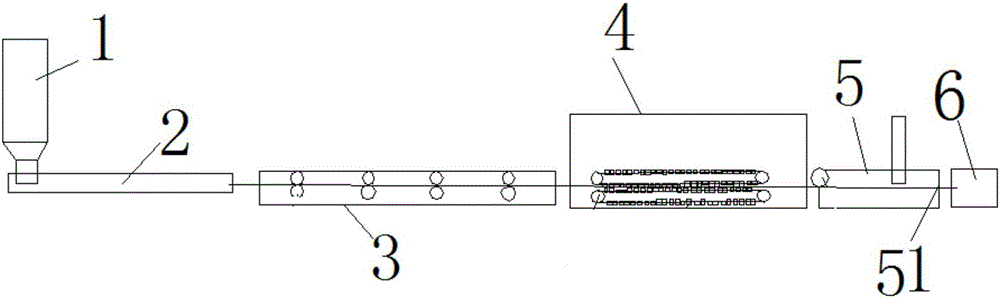

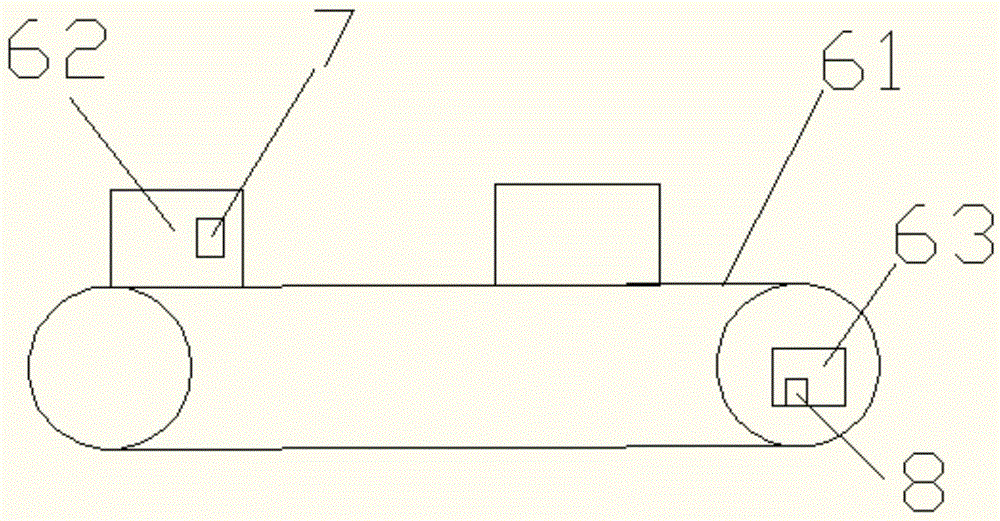

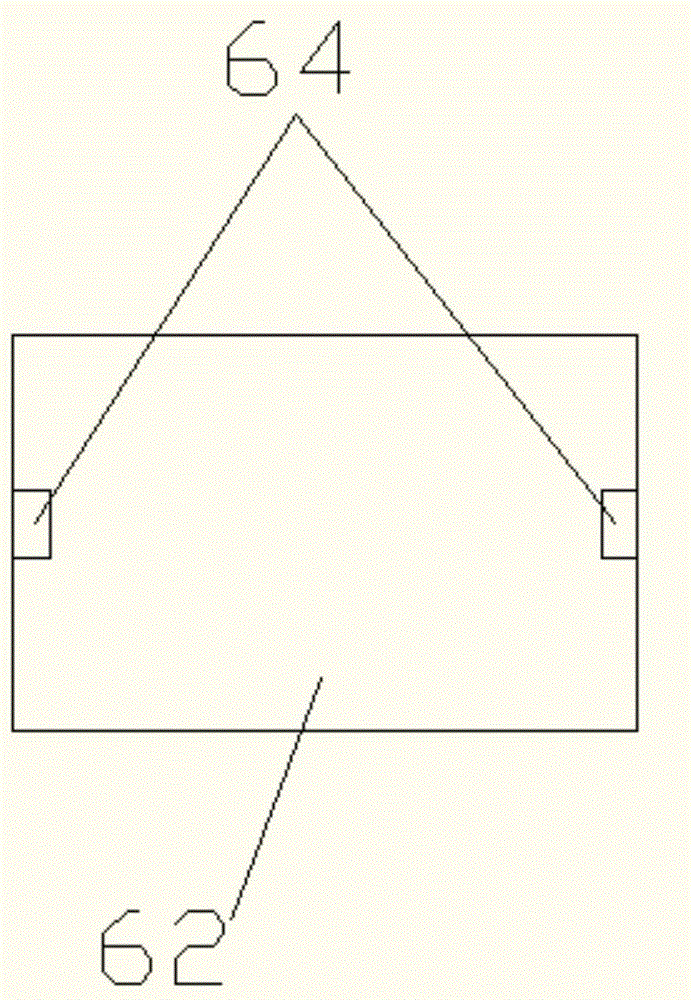

[0018] The plastic pipe production line includes a plastic pipe extruder 2, the plastic pipe extruder 2 is connected with a plurality of auxiliary material extruders, the auxiliary material extruder is connected with the auxiliary material supply device, and the plastic pipe extruder 2 is connected with the main supply The material device 1 is connected, the extrusion head of the plastic pipe extruder 2 is provided with a cooler and a heater, the cooler is connected with the circulating water supply system, and the extrusion head of the plastic pipe extruder 2 is also provided with There is a temperature sensor. The setting of the temperature sensor enables the staff to visually check the temperature of the production device, which is beneficial to control the temperature in the production process. Through the feedback of the temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com