Molding machine for EPS insulation board

The technology of a plate forming machine and a demoulding mechanism, which is applied in the field of decorative plate forming, can solve the problems of easy breakage of finished products, consuming manpower and time, affecting construction efficiency, etc., achieving large finished product size, saving production costs, and saving assembly time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

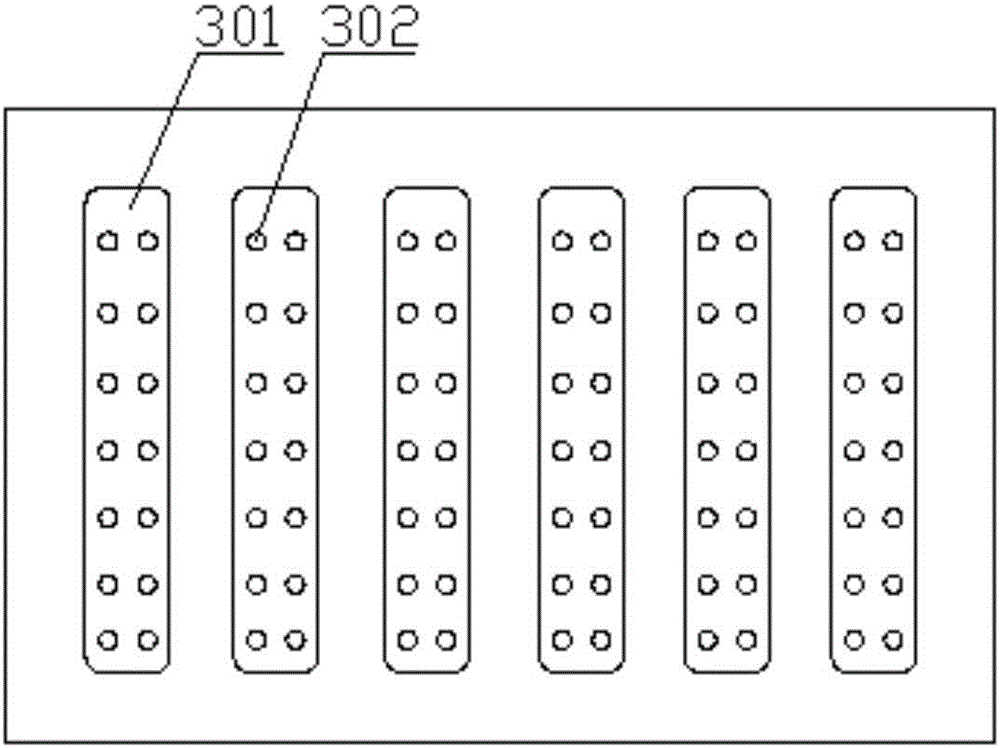

[0013] The invention relates to an EPS insulation board forming machine, comprising a bracket 1, a horizontal guide rod 2 in the bracket 1, and a demoulding mechanism arranged in the bracket 1 for sliding and demoulding by means of the guide rod 2, and the demoulding mechanism is connected with a heating system and cooling system, characterized in that: the demoulding mechanism includes two product molds 3 that slide along the guide rod 2 and are symmetrically arranged, and a top mold mechanism located at both ends of the guide rod 2, and the two product molds 3 are adjacent to each other. A group of symmetrical mold cavities 301 are arranged on the end face of the mold cavity. The thickness of the mold cavity 301 is 80-100mm. The two product molds 3 slide and merge with the guide rod 2 to form the forming cavity of the EPS insulation board. The outer end of the product mold 3 is set There is a top mold hole 302 corresponding to the mold cavity 301. The top mold mechanism inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com