A peanut peeling machine

A technology of fruit machine and peanut, which is applied in the field of peanut peeling machine, can solve the problems of large manpower consumption, affecting the effect of peeling fruit, interference and entanglement of peanuts, etc., and achieves the effect of improving the effect of peeling fruit, easy to use and low in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

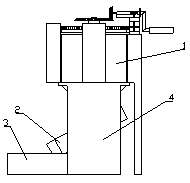

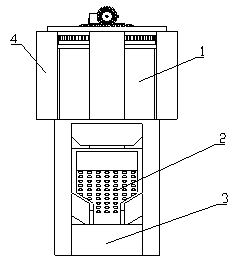

[0039] see Figure 1 to Figure 14 , the present invention provides a peanut peeling machine, comprising a vertical separation mechanism 1, the lower end of the separation mechanism 1 is a discharge port, a sieve box 2 is arranged obliquely below the discharge port, and a receiving box 3 is provided on one side of the sieve box 2, and the sieve box 2 The bottom of the box 2 is provided with a mesh, the separation mechanism 1 and the outside of the sieve box 2 are provided with a bracket 4, the separation mechanism 1 includes a separation cylinder 11, and a clamping mechanism 12 arranged in the separation cylinder 11, and the inner wall of the separation cylinder 11 is provided with a stopper. The plate 10 is provided with a drive mechanism 5 on one side of the separation mechanism 1 , and the clamping mechanism 12 is driven to rotate by the drive mechanism 5 .

[0040] The clamping mechanism 12 includes a rotating drum 121 and a clamp 131. The rotating drum 121 is arranged on t...

Embodiment 2

[0058] On the basis of Embodiment 1, the difference from Embodiment 1 is that the crank handle 54 is replaced by a motor, and the output shaft of the motor is connected with the worm 53 . Change the driving part of the device from manual to electric.

Embodiment 3

[0060] On the basis of Embodiment 1, the difference from Embodiment 1 is that the crank handle 54 is replaced by a turntable. pedal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com