Composite anode for a galvanic cell and a galvanic cell

A primary battery and anode technology, applied to large-size batteries/battery packs, small-size batteries/battery packs, battery electrodes, etc., to avoid deep discharge states, improve service life, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

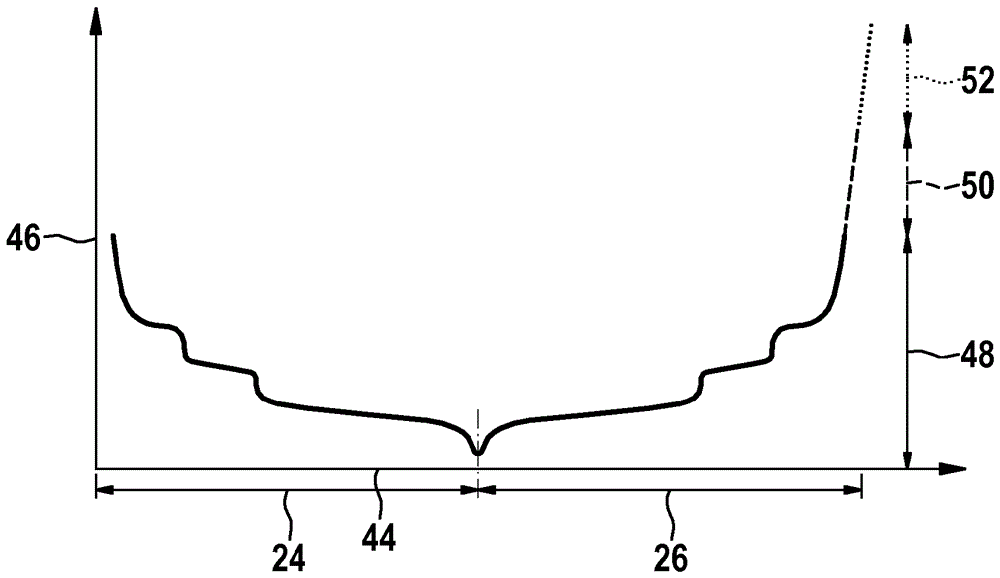

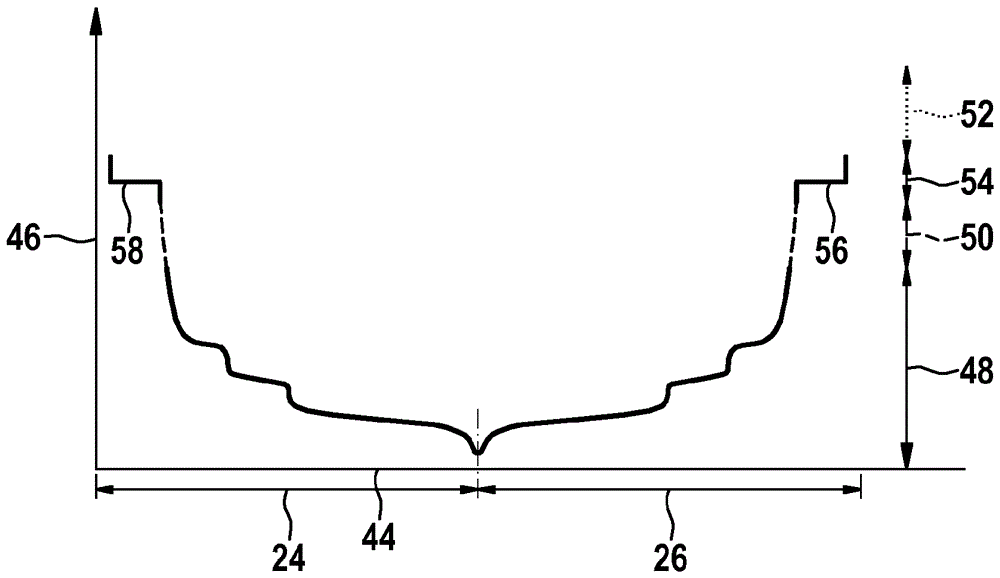

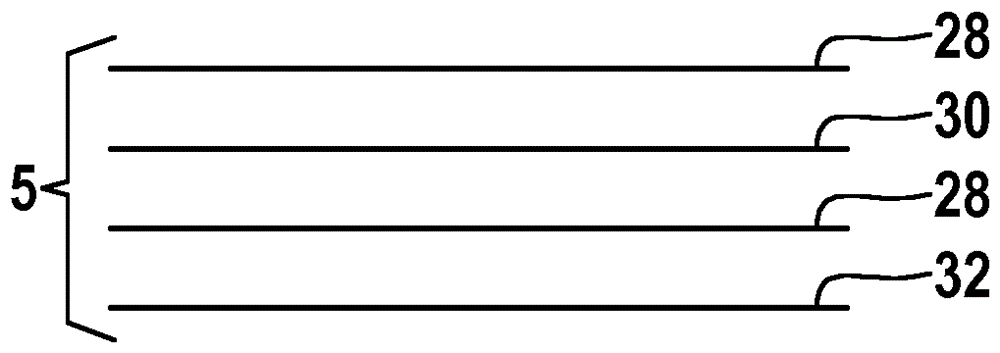

[0039] figure 1 The prismatic battery cell 1 is shown in an exploded view. The prismatic battery cell 1 has a winding element 3 comprising an anode and a cathode, which has a wound layer stack 5 . For electrical contacting, the anodes and the cathodes are stacked on top of each other in a slightly offset manner along the winding axis in opposite directions, so that the anodes and the cathodes project on opposite narrow sides slightly beyond the The corresponding edge of the winding element 3. A current collector 7 is welded onto the raised edge region 4 such that it is electrically connected to the anode of the winding element 3 . A second current collector 9 is welded to the opposite edge region in order to establish electrical contact with the cathode of the winding element 3 . The winding element 3 equipped with current collectors 7 and 9 is located in a hermetically sealed battery housing 11 in which a liquid electrolyte is located. The rectangular parallelepiped batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com