Halbach array permanent magnet face gear set for orthogonal shaft drive

An array type, orthogonal axis technology, applied in the direction of electric components, electromechanical transmissions, permanent magnet clutches/brakes, etc., can solve the problems of limited torque transmission of permanent magnet face gears and bevel gears, and achieve low moment of inertia , cost reduction, large torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

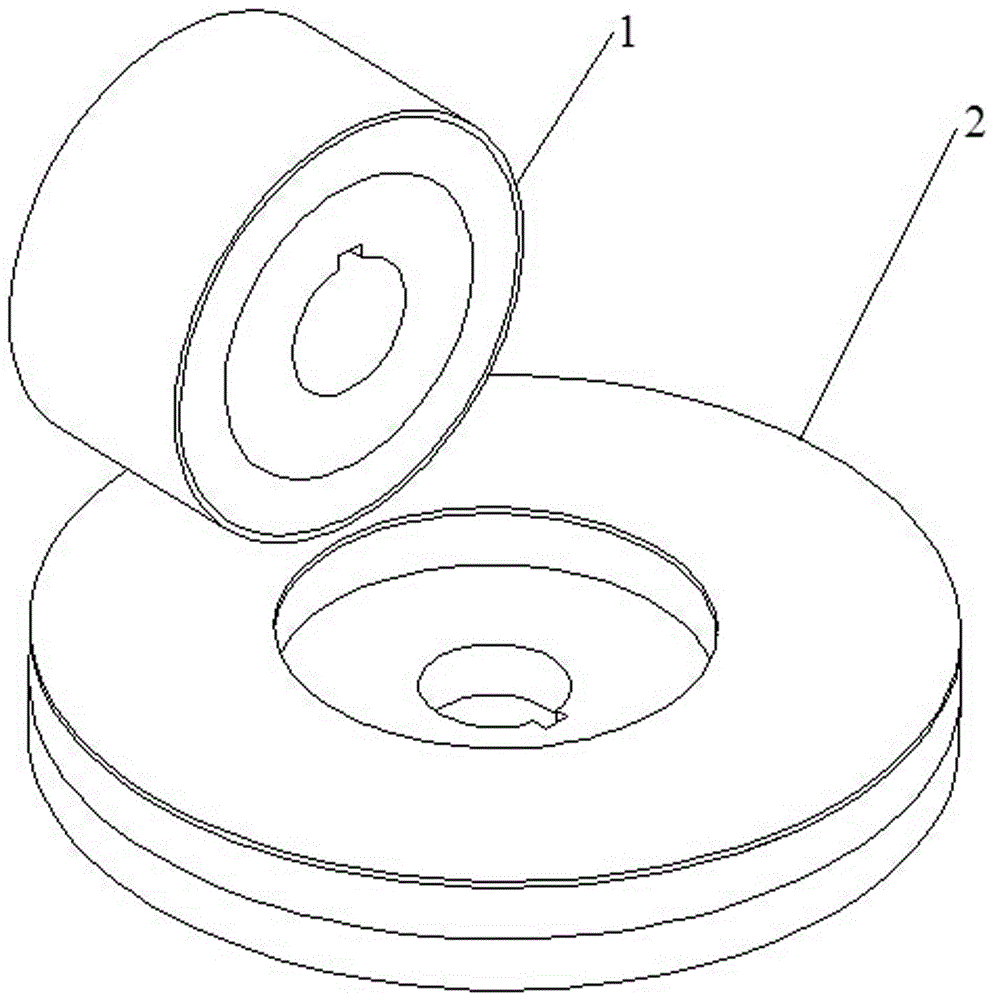

[0027] Specific implementation mode one: as figure 1 , Figure 10 and Figure 11 As shown, a Halbach array permanent magnet face gear set for orthogonal shaft transmission in this embodiment comprises two wheels, the two wheels are magnetic gears, and the two wheels are cylindrical wheels 1 and flat wheel 2, the flat wheel 2 is arranged horizontally, the cylindrical wheel 1 is arranged above the flat wheel 2, and the axis centerlines of the cylindrical wheel 1 and the flat wheel 2 are orthogonal, and the cylindrical wheel 1 and the flat wheel There is an air gap between the two (theoretically, the smaller the air gap, the greater the torque that can be transmitted, but it should be determined comprehensively in combination with the actual installation space and the torque required to be transmitted); when one of the wheels is a driving wheel , the other wheel is a driven wheel, and the driving wheel drives the driven wheel to rotate through magnetic force.

specific Embodiment approach 2

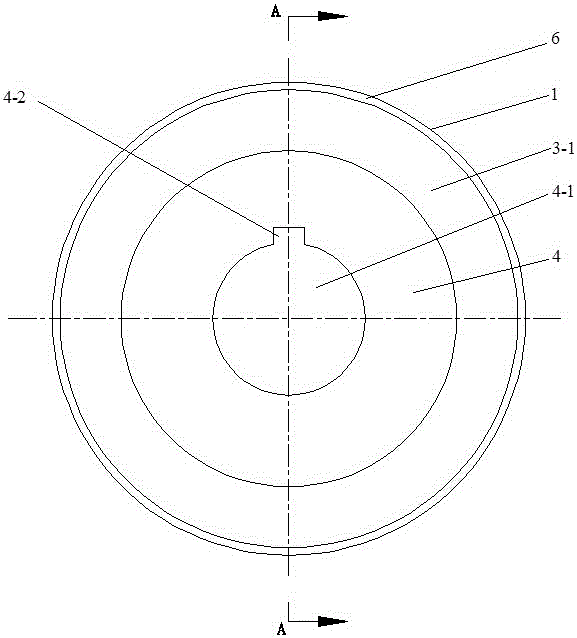

[0028] Specific implementation mode two: as Figure 1~Figure 13 As shown in the first embodiment, a Halbach array permanent magnet face gear set for orthogonal shaft transmission, the cylindrical wheel 1 includes a cylindrical wheel yoke 4 and a plurality of tile-shaped permanent magnets 5; The cylindrical wheel yoke 4 is provided with an axial center hole 4-1, and the inner wall of the axial center hole 4-1 of the cylindrical wheel yoke 4 is provided with a keyway 1 for cooperating with the shafting in the axial direction. 4-2;

[0029] The plurality of tile-shaped permanent magnets 5 includes a plurality of first type tile-shaped permanent magnets 5-1, a plurality of second type tile-shaped permanent magnets 5-2, and a plurality of third type tile-shaped permanent magnets 5-3 and multiple fourth-type tile-shaped permanent magnets 5-4, the multiple first-type tile-shaped permanent magnets 5-1, multiple second-type tile-shaped permanent magnets 5-2, multiple A third-type til...

specific Embodiment approach 3

[0031] Specific implementation mode three: as Figure 2~Figure 4 As shown in the specific embodiment 1 or 2, a Halbach array permanent magnet face gear set for orthogonal shaft transmission, the cylindrical wheel yoke 4 and the plane wheel yoke 11 are all made of non-magnetic materials production.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap