Self-locking device of rotary socket

A technology of self-locking device and socket, which is applied in the direction of preventing contact with live contacts, flexible/rotatable wire connectors, electrical components, etc., can solve the problems that the rotating core does not have the self-locking function and reduces the safety performance of rotation, etc. Achieve the effect of avoiding electric shock and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

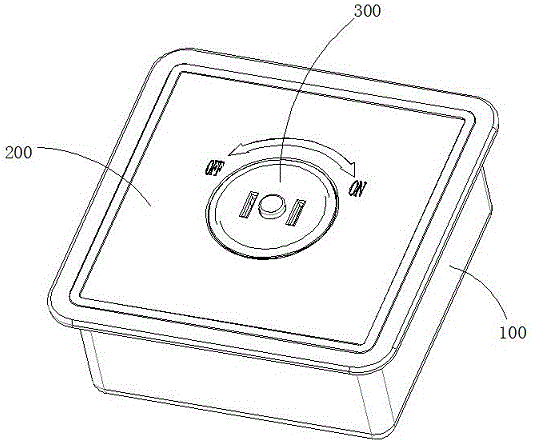

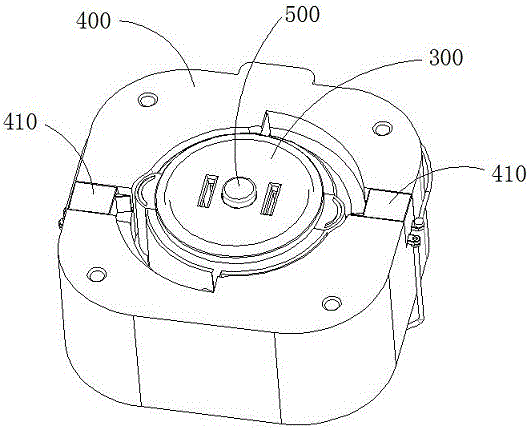

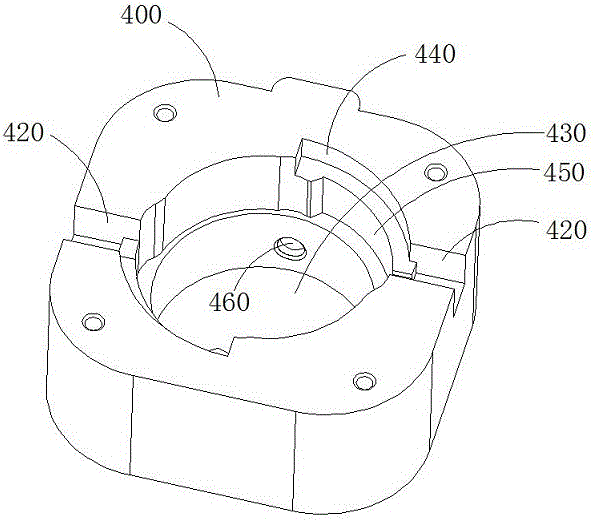

[0026] Such as Figure 1-12 As shown, the anti-electric shock intelligent self-locking socket includes a support body 400, a rotating core 300 that is sleeved in the support body 400 and can rotate around its own axis, a self-locking device 500 installed on the rotating core 300, and the center of the support body 400 There is a rotation hole 430 at the position, and the rotation hole 430 includes an upper rotation hole and a lower rotation hole. The rotation core 300 matches the lower rotation hole of the rotation hole 430 and can rotate around its own axis. Mounting grooves 420 arranged symmetrically at both ends of the hole, the central axes of the mounting grooves 420 at both ends are located on the same extension line and pass through the central axis of the rotating hole 430, and the lower rotating hole is provided with locks arranged symmetrically at both ends of the support body 400 Tight hole 460, the central axes of the locking holes 460 at both ends are located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com