A kind of lug and pole piece transfer structure, battery and manufacturing method thereof

A pole ear and switching technology, applied in the direction of structural parts, circuits, electrical components, etc., can solve the problems of rapid mass production and scale difficulties, difficult soldering of tin, and inability to use, achieve good safety protection performance, reduce explosions and the incidence of combustion, the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

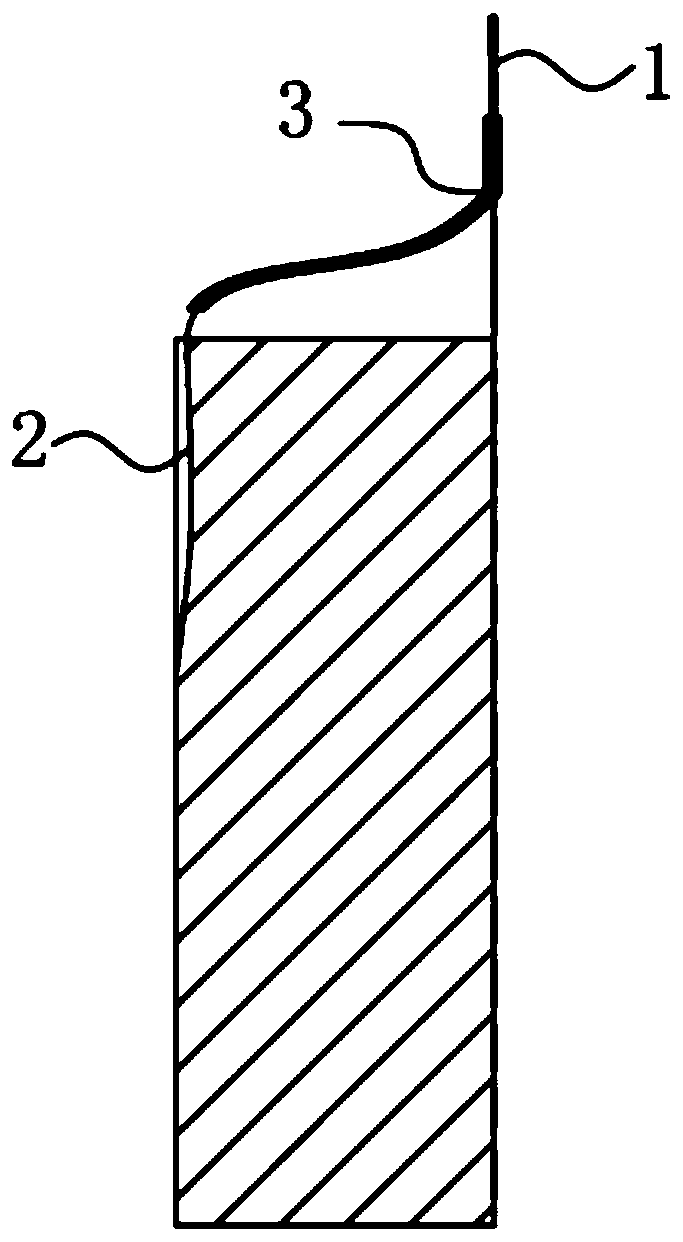

[0033] see figure 1 As shown, this embodiment discloses a tab pole piece transfer structure, including a metal tab 1, a metal strip 2 and an electrode piece, the electrode piece has an electrode collector, and one end of the metal strip 2 is attached to the The other end of the electrode collector surface is connected to the metal tab 1, the thickness of the metal strip 2 is 10-59 μm, the thickness of the metal tab 1 is greater than 50 μm, and the thickness of the metal tab 1 is greater than the thickness of the metal strip 2.

[0034] In this transfer structure, by setting the metal strip 2 with a thickness of only 10-59 μm in direct contact with the electrode collector of the electrode sheet, and then transferring the metal strip 2 through the metal tab 1 of ordinary thickness, it can be as far as possible Avoiding the influence of the thickness of the tab on the overall thickness of the battery, the section thickness of the battery cell using this tab pole piece transfer s...

Embodiment 2

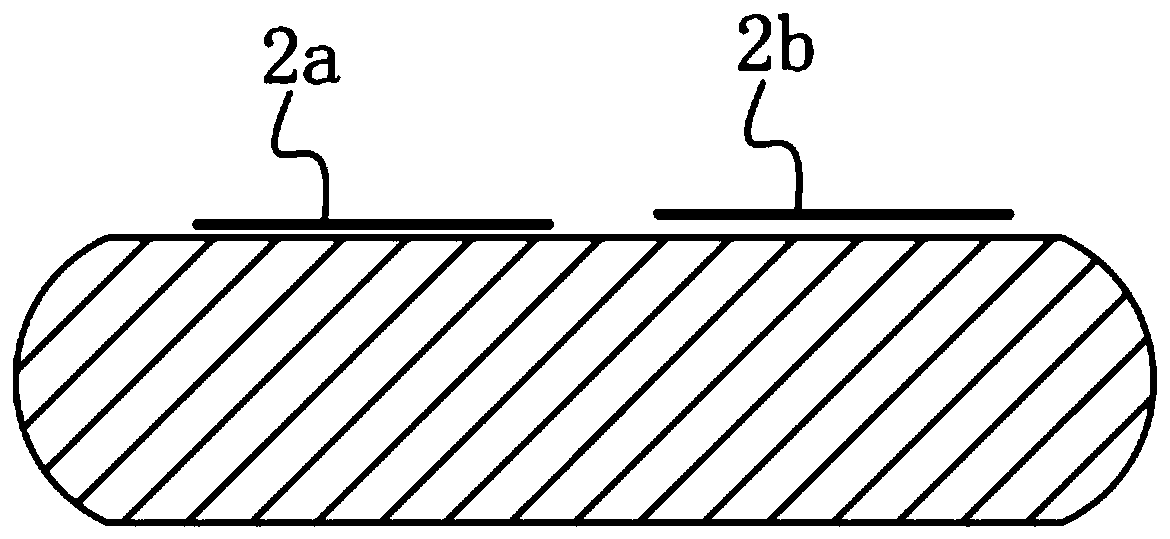

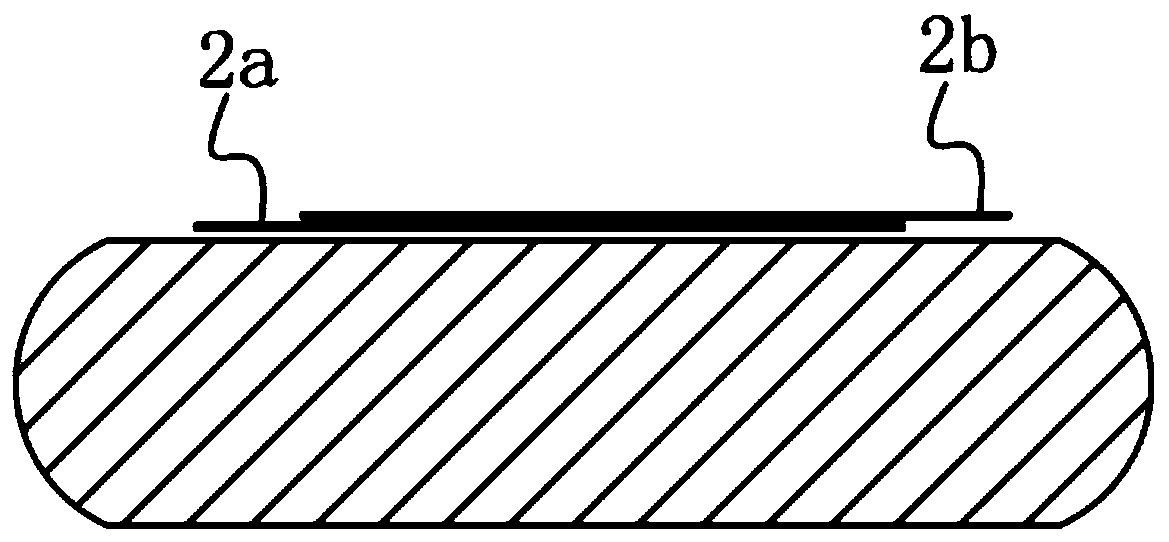

[0048] In another embodiment of the present invention, a battery cell is disclosed, including a diaphragm and the tab pole piece transfer structure as described in Embodiment 1, the number of the tab pole piece transition structures is 2, They are respectively the tab transfer structure of the positive electrode and the tab transfer structure of the negative electrode. The electrode sheet includes a positive electrode sheet and a negative electrode sheet. The positive electrode sheet includes a positive electrode collector and is coated on the positive electrode collector The positive electrode active material on the negative electrode sheet includes a negative electrode current collector and a negative electrode active material coated on the negative electrode current collector. The metal belt 2 includes a positive electrode metal belt 2a and a negative electrode metal belt 2b. The metal tab 1 includes a positive electrode tab and a negative electrode tab. The positive electro...

Embodiment 3

[0057] This embodiment discloses a battery manufacturing method as described in Embodiment 2, which is characterized in that it includes the following steps:

[0058] Ultrasonic welding is performed on the positive electrode metal strip 2a and the positive electrode tab, and ultrasonic welding is performed on the negative electrode metal strip 2b and the negative electrode tab, and the welding points are respectively wrapped with insulating tape 3;

[0059] To obtain a positive electrode sheet and a negative electrode sheet, the end of the positive electrode metal strip 2a away from the positive electrode lug is ultrasonically welded on the positive electrode current collector at the end of the positive electrode sheet, and the positive electrode metal strip 2a is along the length direction of the positive electrode sheet The vertical direction is drawn; the negative electrode metal strip 2b is ultrasonically welded on the negative electrode current collector at the end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com