A thermal switch driven by shape memory alloy in one direction

A technology of memory alloy wire and thermal switch, which is applied to thermal switches, thermal switch parts, electric switches, etc., to achieve the effects of small size, strong applicability, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

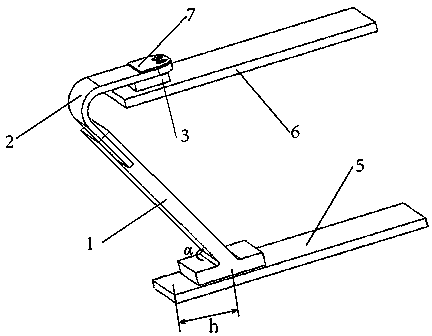

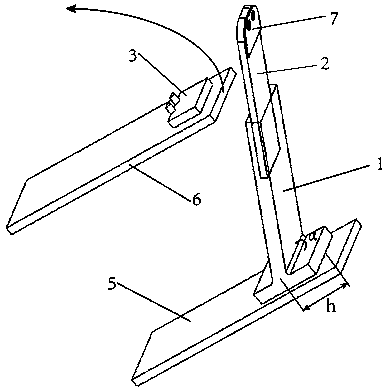

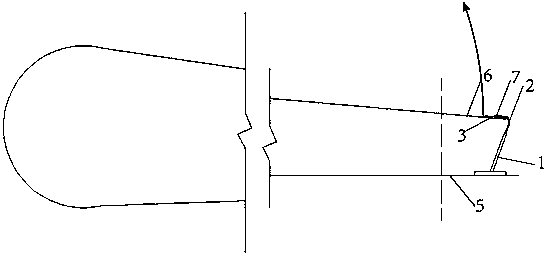

[0023] Such as figure 1 , Figure 4 As shown, the unidirectional drive heat switch of the shape memory alloy of the present invention includes a positioning constraining plate 1, a flexible belt 2, a structural constraining plate 3, a shape memory alloy wire 4 and other components, and the first structural panel 5 is controlled by the switch. and the relative position between the second structural panel 6, and the restraint matching plate 7, the first structural panel 5 and the second structural panel 6 shown in the figure are only part of the actual structural panel, as image 3 As shown, the right side of the dotted line is figure 1 and figure 2 structure representation. When the flexible belt is in the first working state, the first structural panel 5 and the second structural panel 6 are relatively fixed to constrain the movement of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com