Core and coil of triangular three-dimensional wound core transformer and assembly method for core and coil

A three-dimensional wound iron core, transformer coil technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., can solve serious consumables, triangle three-dimensional wound iron core transformer section The advantages of material energy saving cannot be further expanded, and the production of coiled iron cores is troublesome, so as to achieve the effect of saving material costs, enhancing the production process, and making the production and assembly process simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

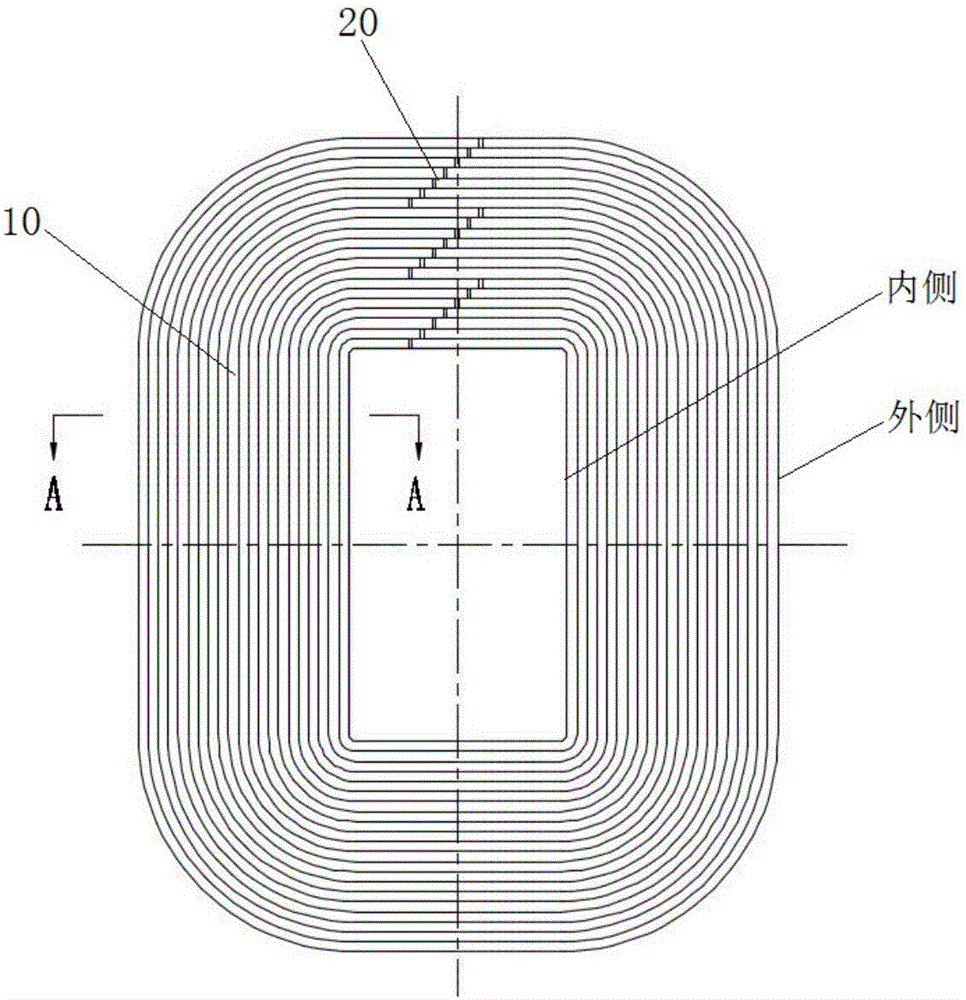

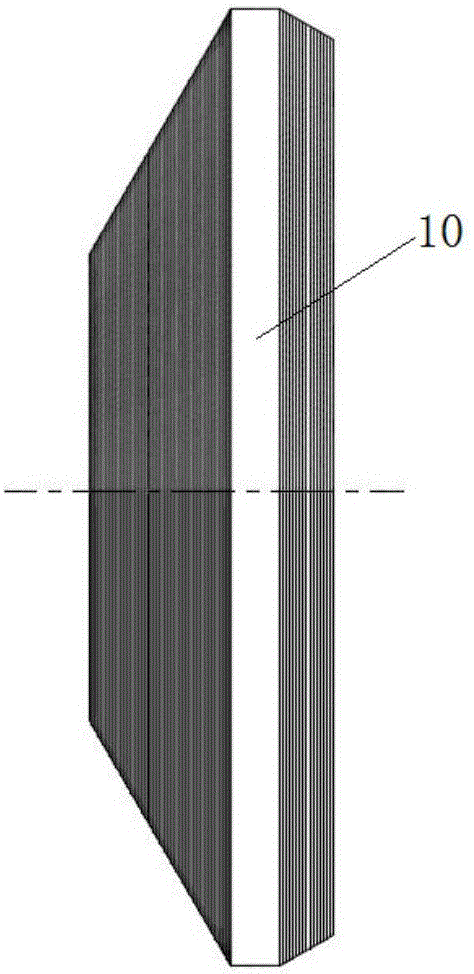

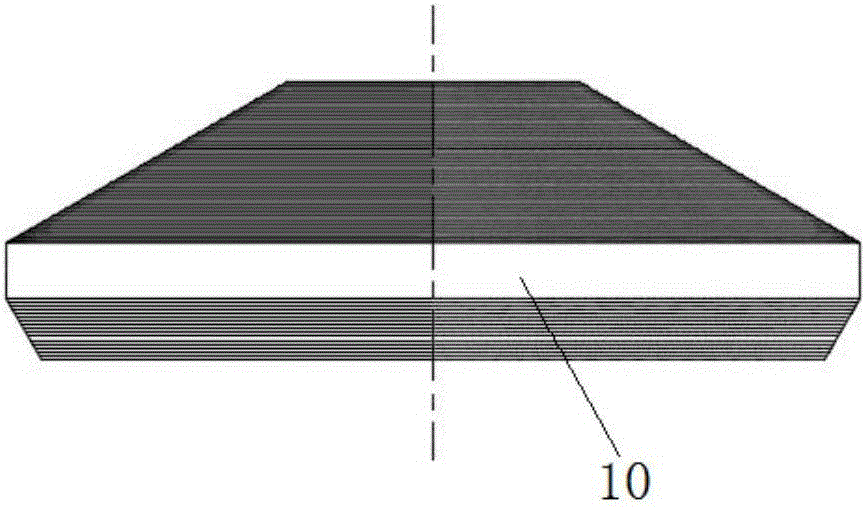

[0052] to combine Figure 8 , Figure 9 with Figure 10 As shown, a triangular three-dimensional wound core transformer core in this embodiment includes three single-frame cores spliced at an angle of 60° to each other, and the three single-frame cores are respectively core one 1, core two 2 and core three 3, The three single-frame iron cores have the same structure, and all have two splicing surfaces 30 at an angle of 120°, and the three single-frame iron cores can be spliced sequentially to form Figure 10 The triangular three-dimensional wound core shown. In this example, if Figure 1 to Figure 4 As shown, the above-mentioned single-frame iron core is rolled or folded by iron core sheets 10 with joints 20. The single-frame iron core is an open-type rolled iron core, and the iron core can be opened to facilitate coil assembly. When using single-frame iron cores, the principle is as follows: the large-width iron core sheet 10 is arranged on the inside of the single-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com