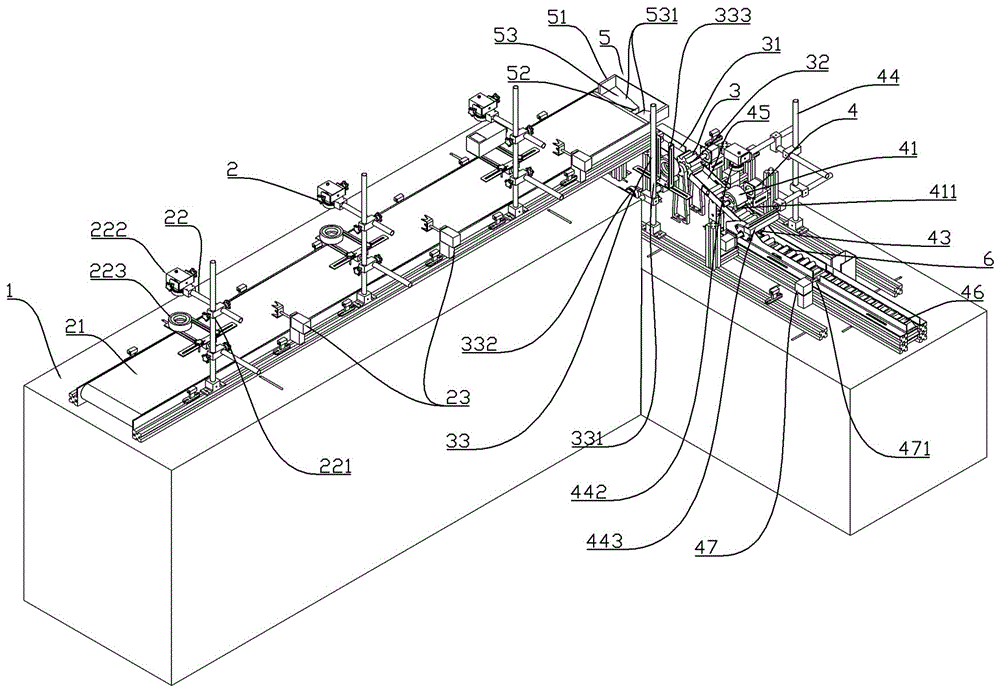

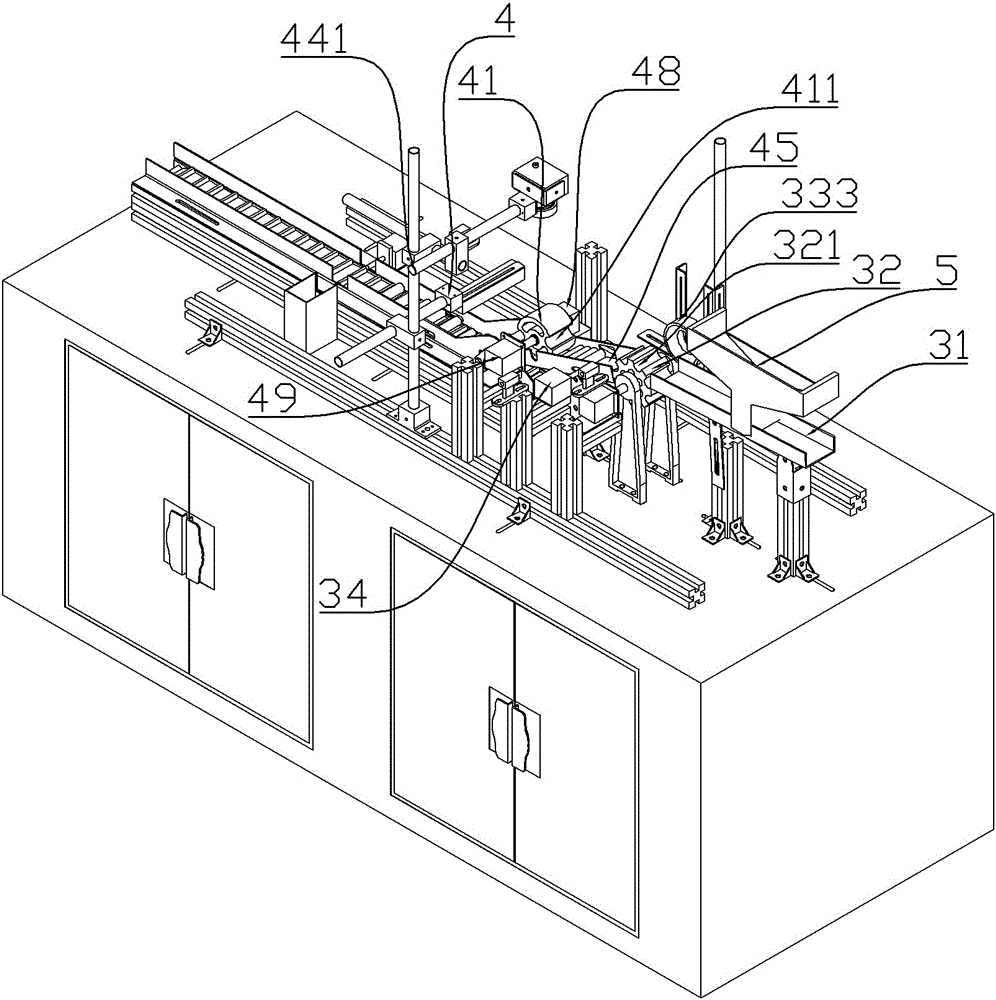

Surface visual inspection pipeline and inner bottom surface detection device for battery cases

A technology for visual inspection and detection device, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low detection efficiency of the detection device, and achieve the effects of solving low detection efficiency, convenient control, and improving accuracy and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

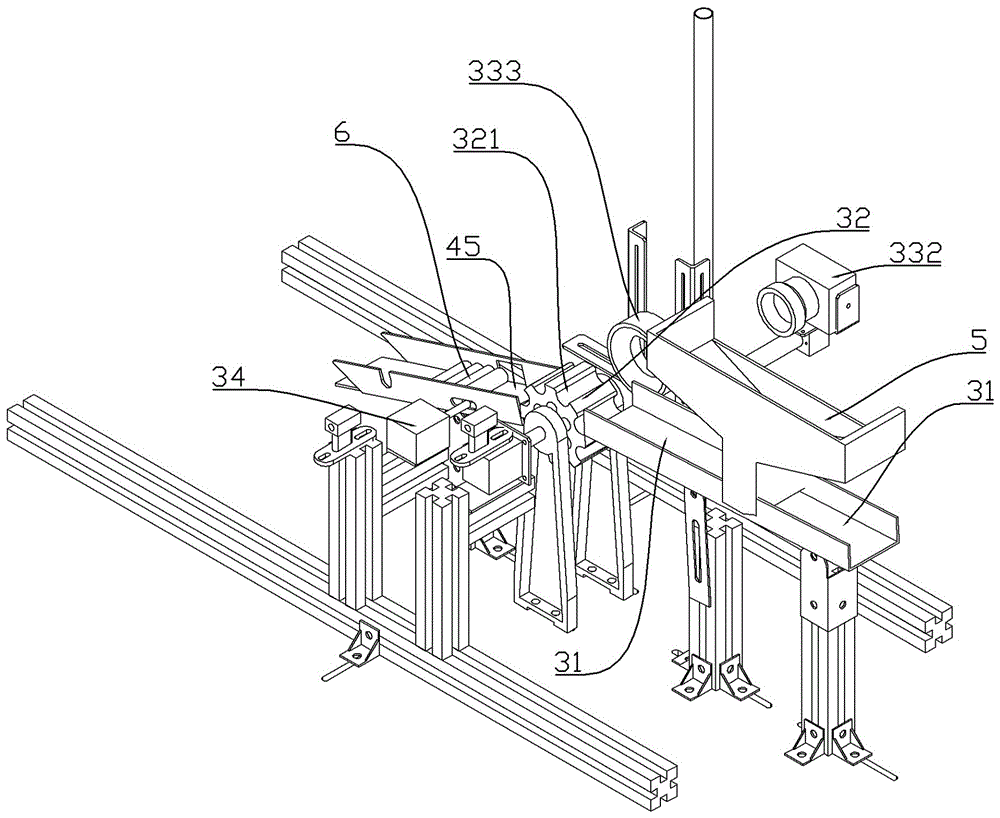

[0059] The specific embodiment 2 of the battery case surface visual detection assembly line of the present invention, the difference between this embodiment and the above-mentioned embodiment is only that: as shown in Figure 7, the calibration port 560 of the battery case attitude adjustment device The plate 550 is surrounded by the wall of the buffer cavity, and the outlet 5410 of the battery case adopts a slope guiding structure 570 .

[0060] A specific embodiment of the detection device for the inner bottom surface of the battery case of the present invention, the structure of the detection device for the inner bottom surface of the battery case is the same as the structure of the detection device for the inner bottom surface of the battery case described in the specific embodiment 1 or 2 of the above-mentioned battery case surface visual detection assembly line Same, no more details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com