Experimental device for testing fracture toughness of rocks under pore pressure condition

A technology of pore pressure and fracture toughness, which is applied in the direction of measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve the problem that the fracture toughness test results cannot get accurate results, do not consider pore pressure, and cannot reflect Solve problems such as the real situation of the stratum, and achieve the effect of simple structure, accurate fracture toughness and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of a preferred embodiment of the present invention will now be described with reference to the accompanying drawings.

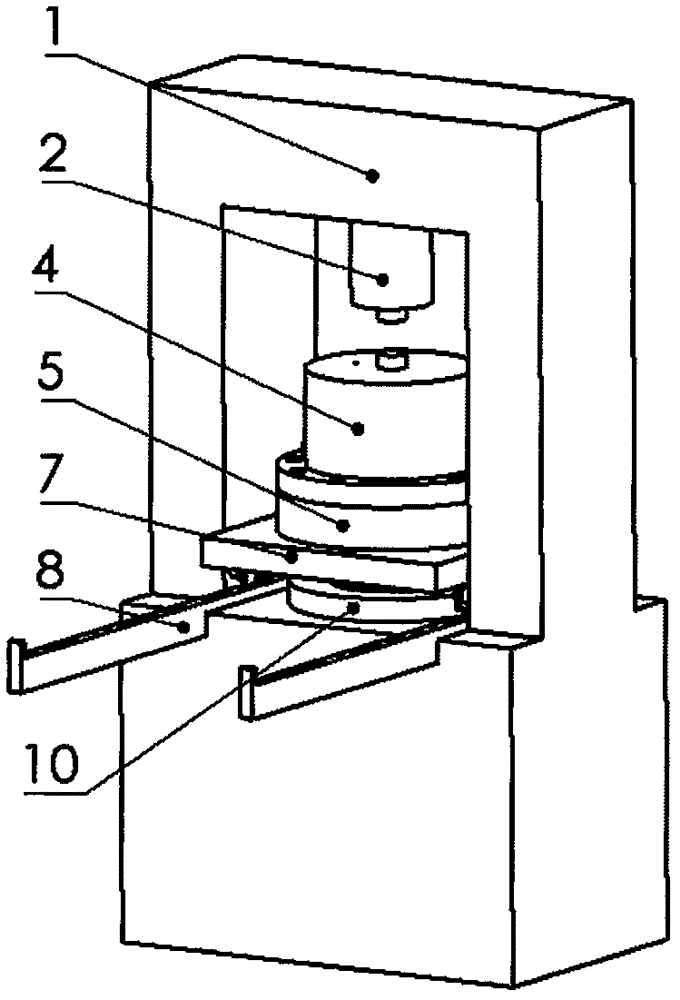

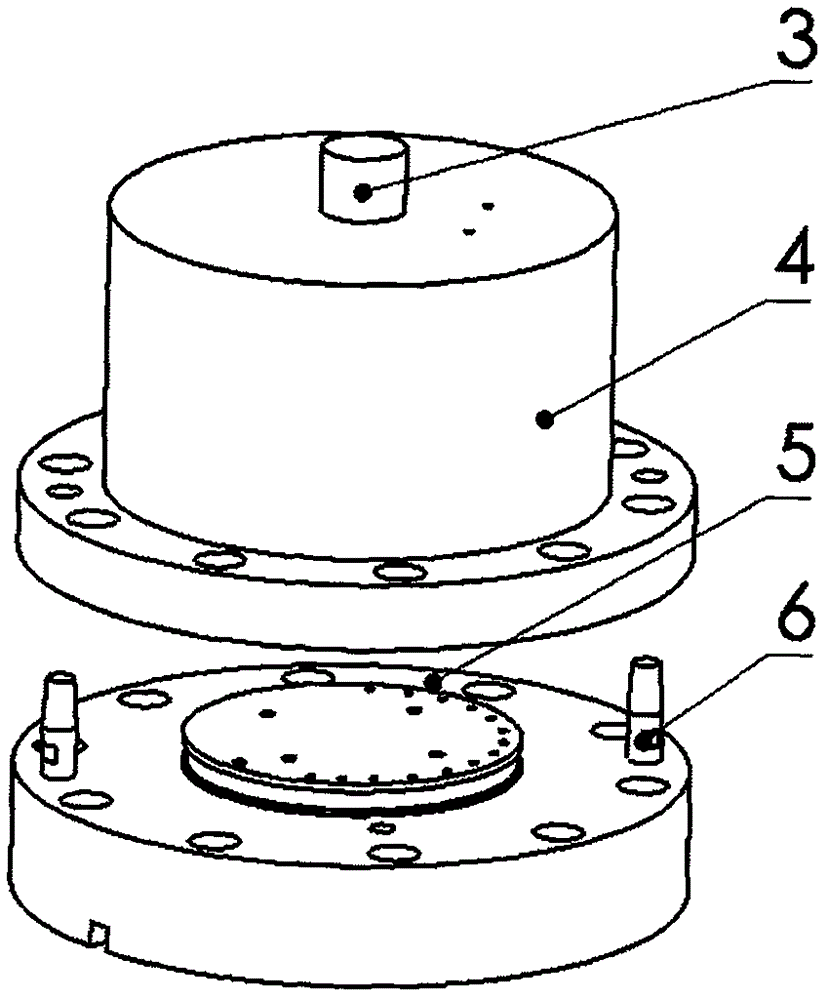

[0039] Figure 1-Figure 6 Shown is an experimental device for testing rock fracture toughness under pore pressure conditions, which includes a testing machine, a confining pressure chamber and a clamping fixture. The testing machine includes testing machine rigid frame 1, rigid frame pressure head 2, trolley 7, slide rail 8, hydraulic shaft 9, hydraulic cylinder 10, rigid frame pressure head 2 is installed on the upper end of testing machine rigid frame 1, and rigid frame pressure head 2 is installed on the lower end of testing machine rigid frame 1. Hydraulic cylinder 10, there is a hydraulic shaft 9 inside the hydraulic cylinder 10, the trolley 7 is located on the platform of the rigid frame 1 of the testing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com